Trim installation – Newport Brass 1-570 User Manual

Page 3

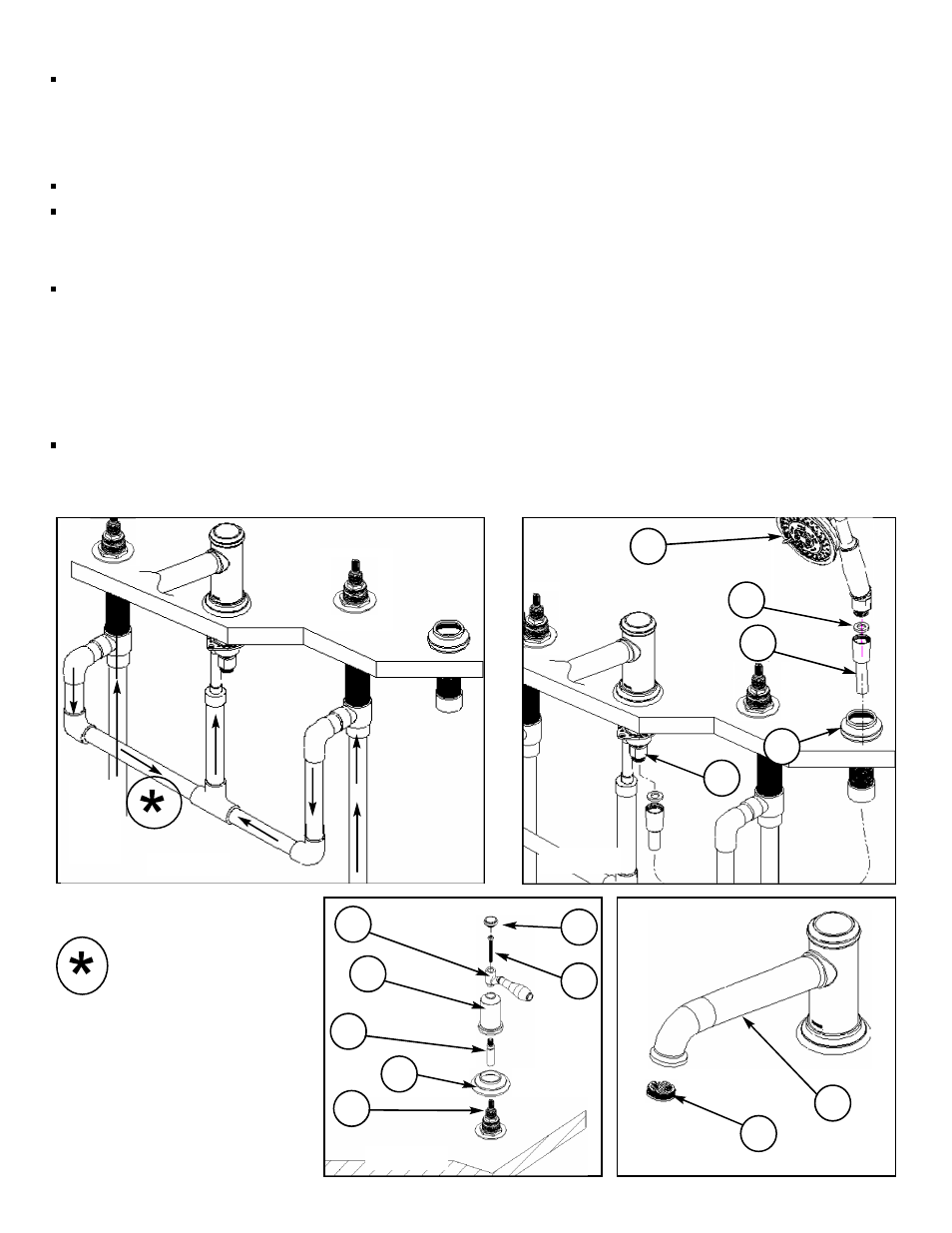

Trim Installation

Utilizing 3/4” copper pipe, make connections between spout, valves & water supply.

See Figure 4.

Warning: To prevent severe damage to valve body, any solder/braze process must be

performed a min. of 4" from ports.

Apply thread sealant and insert a rubber WASHER (16) into each end of HOSE (15).

Attach one end of HOSE (15) to diverter OUTLET (14). Pull other end through deck

FLANGE (18) and attach to hand SHOWER (19). Place hand SHOWER (19) into deck

FLANGE (18). See Figure 5.

Install ESCUTCHEON (21), place broached ROD (27) with o-ring onto STEM (22). Tighten

BONNET (26) over ROD (27) and onto ESCUTCHEON (21). Install LEVER (25) over

BONNET (26). Align & secure with SCREW (24). Press end CAP (23) with o-ring into

top of LEVER (25). Note: Any adjustments for rotational alignment must be made to

the valve BODY (2), not to the CARTRIDGE (22). Repeat for all handles. See Figure

6. (Cartridge Bonnet factory torque is 14-16 ft-lbs.)

Using a thin blade screwdriver, remove AERATOR (28) from SPOUT (8). Turn on water

supply, and flush both valves until water is clear. Check for leaks and make any final

adjustments required. Re-attach AERATOR (28) to the SPOUT (8). See Figure 7.

Figure 4

Inlet

for hot

water

supply

Inlet for cold

water supply

Figure 6

22

21

23

25

28

8

Figure 5

Figure 7

15

14

18

24

26

27

19

16

Note: Some states

require a ASSE 1016

approved Tempering

Valve installation with

this product. See the fol-

lowing disclaimer for

proper installation.

NWP-1-570