Newport Brass 1-563 User Manual

In-wall lavatory kit, Installation instructions, Model no. 1-563

In-Wall Lavatory Kit

Installation Instructions

Model

No. 1-563

We recommend Installation of this product by a Professional Plumbing Contractor

Note: Use Teflon tape or equivalent to seal all threaded port joints.

Warning: To prevent severe damage to valve body, any solder/braze process must be performed a min. of 4” from

ports.

Important: REMOVE CARTRIDGE FROM VALVE BODY (1) PRIOR TO APPLYING ANY HEAT/FLAME.

Utilizing a 3/4” copper supply piping, thread or sweat pipe fittings into inlets of valve BODY (1), (blue STEM (4) is cold,

red STEM (5) is hot). If sweating supplies directly to valve inlets, remove cartridges during this process.

Note: If cartridges are removed during installation, re-torque to factory specification of 14-16 ft-lbs.

Attach supply source to inlet of VALVE (1). Water flow direction is indicated by "ARROW" on side of body.

Attach end device to outlet of VALVE (1).

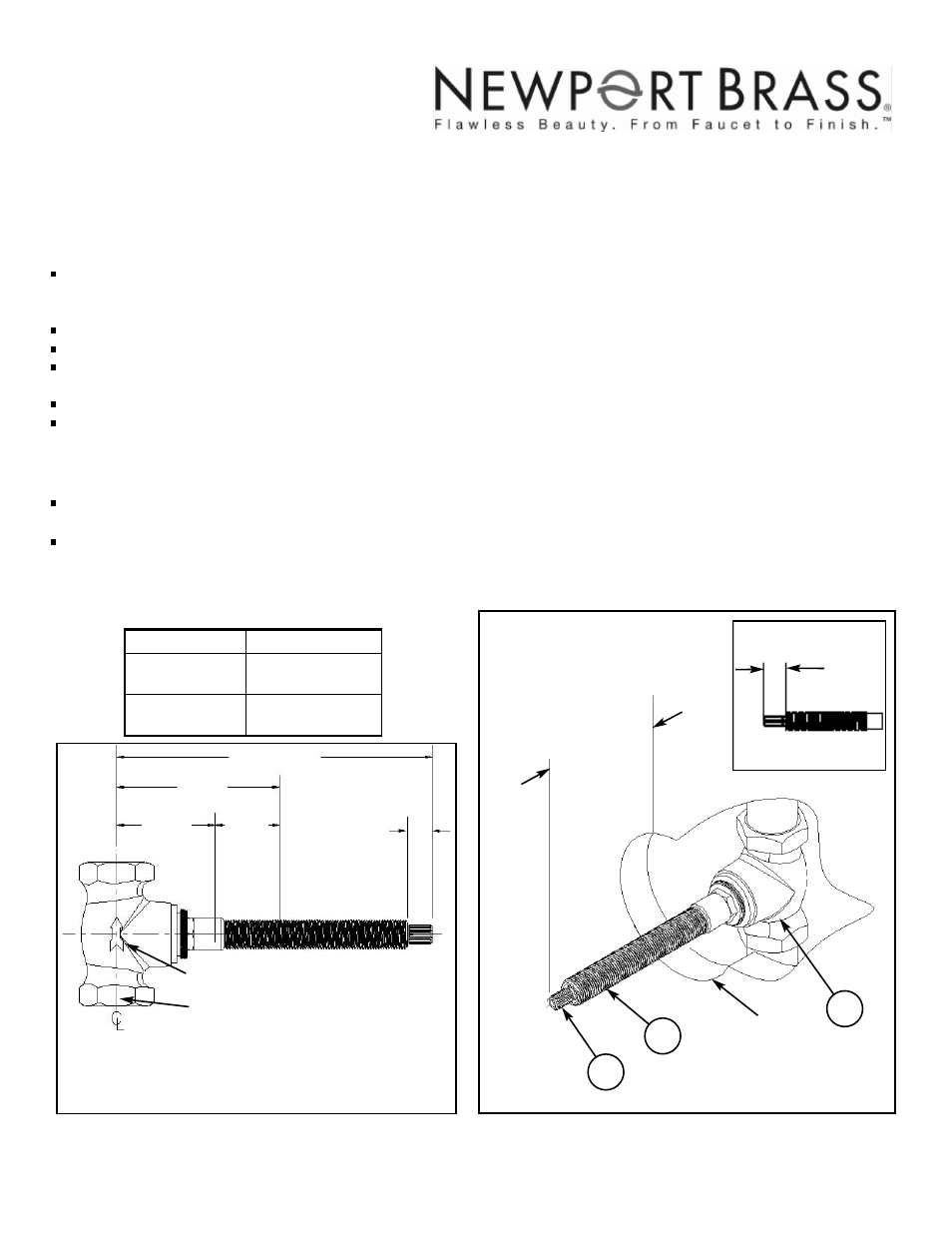

Position VALVE (1) in wall as shown below. These dimensions are for typical installations. If thick finished wall materi-

als are to be used in construction, it is recommended that VALVE (1) is positioned toward outer face of stud.

Support VALVE (1) and/or piping to stud framing using strap tape or equivalent.

Turn on water supply, pressurize system and check for leaks.

Finished wall dimensions are shown in Figure 2.

Finished wall surface must be completed before proceeding.

Measuring and cutting stem length:

Remove ALL-THREAD (3) and indicate on STEM (2) a measured distance, (see Table 1), from finished wall surface. Using

a hacksaw, cut off excess length of STEM (2).

Trim additional 1/2” of ALL- THREAD (3) length from end of STEM (2). See Figure 1A.

For handle trim attachment, the following table shows required stem length from finished wall:

Stem Length

Trim Model #

1-5/16”

3-424

3-423

1-3/16”

3-425

1/2”

See Table 1

Finished wall

3

2

Figure 1A

Figure 1

6”

max.

f

inished wall

1/2”

*

3”

1-1/4”

Face of stud

Outlet

Inlet

2 x 3/4-14 NPT (1-563)

*

1-3/4”

Direction of water flow

*

If finished wall material is thicker than stated “Mud/ Tile max”, then the

“Face of stud” dimension must be less than shown.

Mud/

Tile

max.

Ø1”

1

Figure 2

Table 1

NWP 1-563

EN-2446

REV -

01/25/2013

2001 CARNEGIE AVE, SANTA ANA CA 92705

(949) 417-5207

WWW.NEWPORTBRASS.COM