Max1664, Table 2. typical dc-dc 2 operation, Diode selection – Rainbow Electronics MAX1664 User Manual

Page 12: Filter capacitor selection

MAX1664

12

______________________________________________________________________________________

Diode Selection

The MAX1664’s high switching frequency requires fast

diodes. Schottky diodes such as the MBR0520L and

MBR0540L (Motorola) are recommended because they

have the necessary power ratings in a low-height SOD-

123 package. Also recommended is the MBRM5817

which is 1.1mm high. Use a Schottky diode with a for-

ward current rating greater than:

For the positive output of DC-DC 2, use a Schottky

diode with a voltage rating that exceeds V

OUT2+

. For

the negative output, use a Schottky diode with a rating

that exceeds V

IN

+

V

OUT2-

. See Table 3 for more

information on Schottky diode manufacturers.

Filter Capacitor Selection

An output filter capacitor’s ESR and size can greatly

influence a switching converter’s output ripple, as

shown in the following equation.

V

I

x R

I

t

C

DC - DC 1 t

1

f

V

V - V

V

V

DC - DC 2 t

1

2 f

RIPPLE(PK PK)

PEAK

ESR

OUT

ON

OUT

ON

DC -DC 1

OUT1

F

IN

OUT1

F

ON

DC -DC 1

−

≅

+

=

+

+

=

.

I

I

V

V

F

OUT

OUT

IN

>

0 9

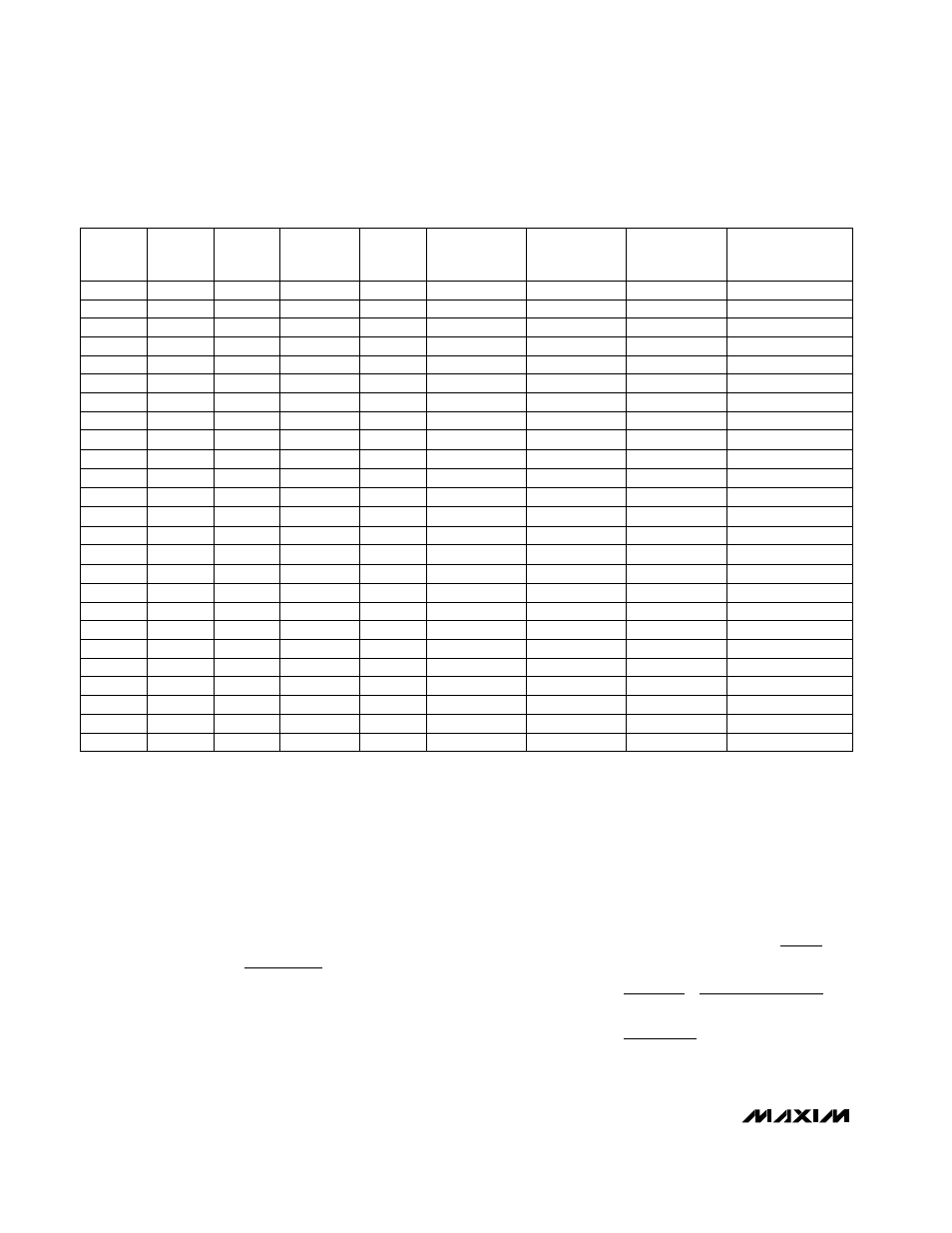

Table 2. Typical DC-DC 2 Operation

*

Note: Absolute maximum peak current at LX2P and LX2N is 750mA.

Active Matrix Liquid Crystal Display

(AMLCD) Supply

INDUCTOR PEAK

CURRENT*

(mA)

f

DC-DC 2(MAX)

(kHz)

I

OUT2-(MAX)

(mA)

I

OUT2+(MAX)

(mA)

L2

(µH)

f

BPCLK

(kHz)

V

IN

(V)

V

OUT2-

(V)

V

OUT2+

(V)

500

480

15

10

4.7

30.0

5.0

-10

+20

550

400

18

10

4.7

25.0

5.0

-10

+20

640

360

20

11

4.7

22.5

5.0

-10

+20

679

480

17

10

2.7

30.0

4.5

-10

+20

450

480

12

8

4.7

30.0

4.5

-10

+20

500

400

14

8

4.7

25.0

4.5

-10

+20

580

360

16

9

4.7

22.5

4.5

-10

+20

496

480

8

4

4.7

30.0

3.3

-10

+20

340

480

5

4

4.7

30.0

3.3

-10

+20

583

400

10

6

2.7

25.0

3.3

-10

+20

370

400

7

4

4.7

25.0

3.3

-10

+20

643

360

12

6

2.7

22.5

3.3

-10

+20

425

360

8

4

4.7

22.5

3.3

-10

+20

451

480

6

3

2.7

30.0

3.0

-10

+20

300

480

4

3

4.7

30.0

3.0

-10

+20

530

400

8

4

2.7

25.0

3.0

-10

+20

340

400

5

2

4.7

25.0

3.0

-10

+20

585

360

10

5

2.7

22.5

3.0

-10

+20

385

360

6

3

4.7

22.5

3.0

-10

+20

600

360

43

20

4.7

22.5

5.0

-5

+15

550

360

35

15

4.7

22.5

4.5

-5

+15

643

360

27

10

2.7

22.5

3.3

-5

+15

425

360

19

7

4.7

22.5

3.3

-5

+15

585

360

23

8

2.7

22.5

3.0

-5

+15

375

360

15

6

4.7

22.5

3.0

-5

+15