Model 5600sf, Trouble-shooting, Page 22 – Peerless Water 5600_5600 Econominder User Manual

Page 22

Printed in U.S.A.

Page 22

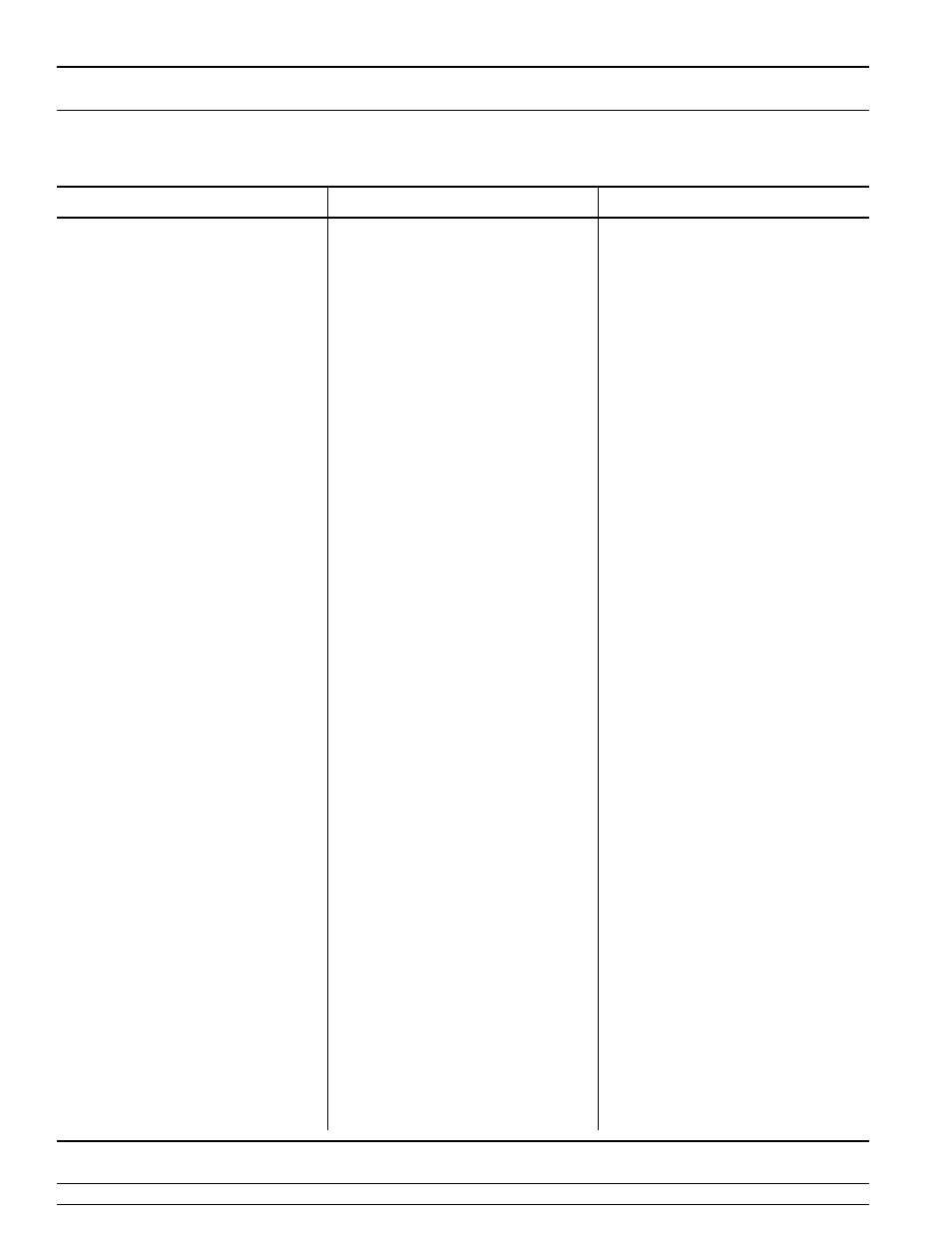

MODEL 5600SF

Trouble-Shooting

PROBLEM

CAUSE

CORRECTION

1.

Filter fails to backwash.

A.

Electrical Service to unit has been

interrupted.

B.

Timer is Defective.

C.

Power Failure.

A.

Assure Permanent Electrical Ser-

vice (Check Fuse, Plug, Pull

Chain or Switch).

B.

Replace or replace timer.

C.

Reset time of Day.

2.

Filter “bleeds” iron.

A.

By-pass valve is open.

B.

Excessive water usage.

C.

Hot water tank rusty.

D.

Leak at distributor tube.

E.

Defective or stripped filter medium

bed.

F.

Inadequate backwash flow rate.

A.

Close by-pass valve.

B.

Reduce days between,

backwashing (see timer

instructions.) Make sure that there

is not a leaking valve in the toilet

bowl or sinks.

C.

Repeated flushings of the hot

water tank is required.

D.

Make sure distributor tube is not

cracked. Check O-ring and tube

pilot.

E.

Replace bed.

F.

Make sure filter has correct drain

flow control. Be sure flow control

is not clogged or drain line

restricted. Be sure water pressure

has not dropped. Increase

backwash flow rate according to

specifications for your unit. See

your dealer for recommendations.

3.

Loss of water pressure.

A.

Iron or turbidity buildup in water fil-

ter.

B.

Inlet of control plugged due to

foreign material broken loose from

pipes by recent work done on

plumbing system.

A.

Reduce days between backwash-

ing so filter backwasher more

often. Note: Make sure filter is

sized large enough to handle

water usage.

B.

Remove piston and clean control.

4.

Loss of filter medium through drain

line.

A.

Broken or missing top screen.

A.

Replace top screen, must have

.020

″

wide slots.

5.

Drain flows continuously.

A.

Foreign material in control.

B.

Internal control leak.

C.

Control valve jammed in rinse or

backwash.

A.

Remove piston assembly and

inspect bore, remove foreign

material and check control in vari-

ous cycle position.

B.

Replace seals and/or piston

assembly.

C.

Replace piston and seals and

spacers. (and drive motor if

necessary).