Trouble-shooting, Page 20 – Peerless Water 5600_5600 Econominder User Manual

Page 20

Printed in U.S.A.

Page 20

MODEL 5600 & 5600 ECONOMINDER

®

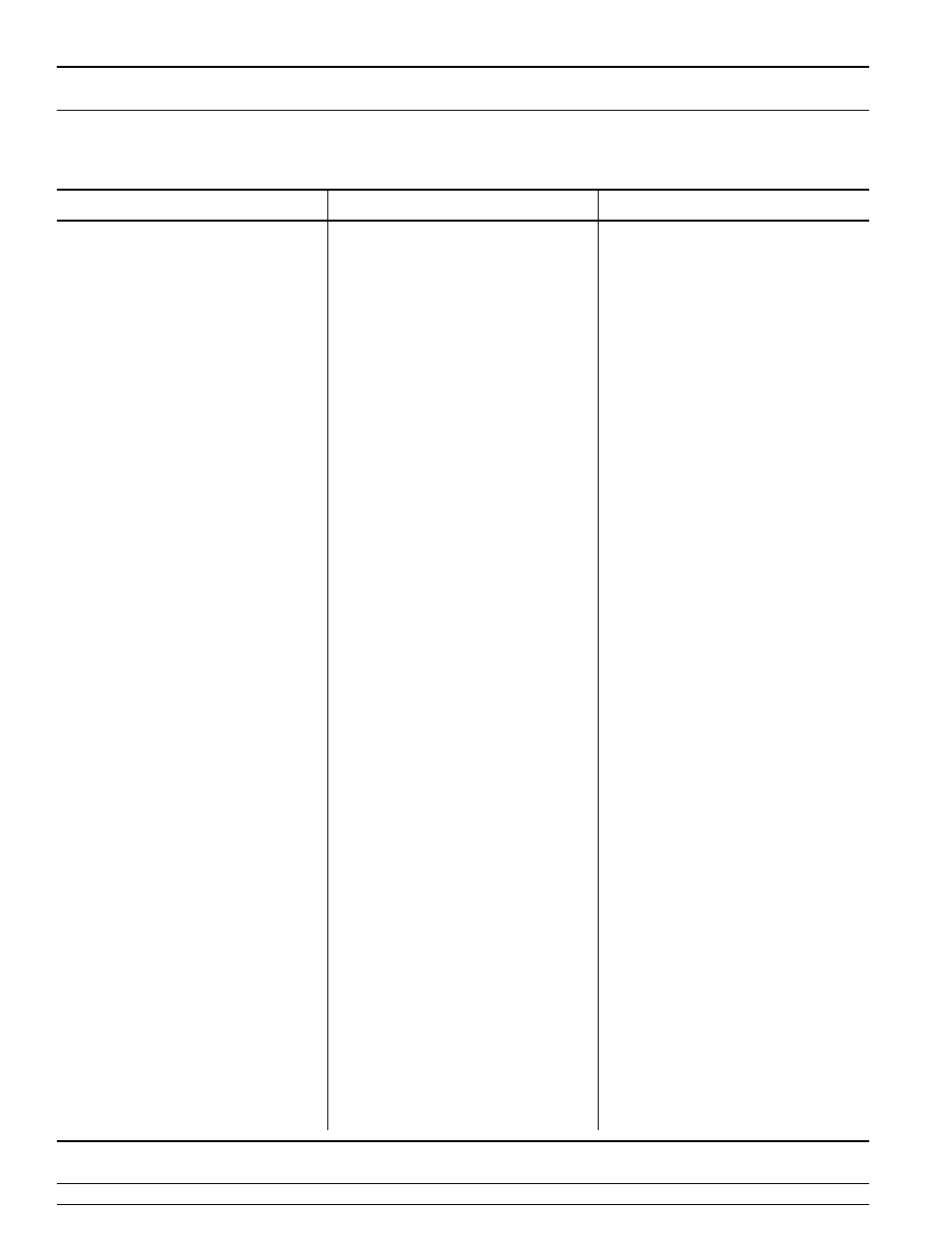

Trouble-Shooting

PROBLEM

CAUSE

CORRECTION

1.

Softener fails to regenerate.

A.

Electrical service to unit has been

interrupted.

B.

Timer is defective.

C.

Power failure.

A.

Assure permanent electrical ser-

vice (check fuse, plug, pull chain

or switch).

B.

Replace timer.

C.

Reset time of day.

2.

Softener delivers hard water.

A.

By-pass valve is open.

B.

No salt in brine tank.

C.

Injectors or screen plugged.

D.

Insufficient water flowing into

brine tank.

E.

Hot water tank hardness.

F.

Leak at distributor tube.

G.

Internal valve leak.

A.

Close by-pass valve.

B.

Add salt to brine tank and

maintain salt level above water

level.

C.

Replace injectors and screen.

D.

Check brine tank fill time and

clean brine line flow control if

plugged.

E.

Repeated flushings of the hot

water tank is required.

F.

Make sure distributor tube is not

cracked. Check O-ring and tube

pilot.

G.

Replace seals and spacers and/or

piston.

3.

Unit uses too much salt.

A.

Improper salt setting.

B.

Excess water in brine tank.

A.

Check salt usage and salt setting.

B.

See problem No. 7.

4.

Loss of water pressure.

A.

Iron buildup in line to water

conditioner.

B.

Iron buildup in water conditioner.

C.

Inlet of control plugged due to

foreign material broken loose from

pipes by recent work done on

plumbing system.

A.

Clean line to water conditioner.

B.

Clean control and add resin

cleaner to resin bed. Increase

frequency of regeneration.

C.

Remove piston & clean control.

5.

Loss of resin through drain line.

A.

Air in water system.

A.

Assure that well system has

proper air eliminator control.

Check for dry well condition.

6.

Iron In Conditioned Water.

A.

Fouled resin bed.

A.

Check backwash, brine draw and

brine tank fill, increase frequency

of regeneration.

Increase backwash time.

7a. Excessive water in brine tank.

A.

Plugged drain line flow control.

A.

Clean flow control.