Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1391 User Manual

Page 20

20

Assembly

PNEG-1391 8",10", & 12" BE-SAW Augers

4. OPTIONAL 10" & 12" LOW PROFILE HOPPER ASSEMBLY INSTRUCTIONS (See Figure 4-A)

Install bolt heads to the

inside and DO NOT tighten

completely. The coupler

box must be able to pivot.

Do NOT tighten the nuts

down. The lid straps must

be allowed to slide when

the incline tube is tilted at

different angles.

There are two installation

heights for the hopper wheels.

For the shortest hopper

profile, use the upper set of

holes. Also use the holes to

angel the wheels by using

opposite holes.

B. Fasten the U- Joint to the incline tail stub us-

ing one 3/8" x 3" long (grade 5) HHCS and

stover nut.

C. Connect the U-Joint to the power shaft in the

swing-out hopper using one (1) 3/8" x 3" long

(grade 5) HHCS and stover nut.

D. Fasten the lower end of the incline tube to the

front of the swing away hopper. Use two 1/2"

x 1-1/2" long (grade 5) HHCS, flat washers,

and nylon locknuts.

E. Bolt hopper lid to the front of the swing out

hopper using three (3) 5/16" x 3/4" long (grade

5) HHCS flat washers, and nylon locknuts.

F. Install lid strap onto 3/8" stubs welded onto

lower end of incline tube. Hold the straps on

the stud with 3/8" nylon locknuts.

G. Low Profile Swing-Out Hopper Rubber

Belting Assembly (See Figure 4-A)

1. Install the rubber belting into the inside of

the swing out hopper. Use ten (10) long

and four (4) short attachment clips to install

the belting. Two (2) 1/4" x 1" long hex head

capscrews and nylon locknuts are used

for each clip. Loosely attach each clip with

grip teeth of clips up and with bolt heads

inside the hopper. Use bolt holes

positioned around upper edge of hopper.

2. Set the belting inside the clips with the

belting edge resting on the bolts. (See

Figure 4-C) The belting does not go

completely across the output end of the

hopper. The belting is notched to

accommodate the center guard support

at the rear of the hopper. Begin installing

the belting at this point and work each way

toward the hopper discharge. Keep the

belting end within one inch of the clip end.

Position the belting evenly around the

hopper and through the corners.

3. Tighten the bolts and nuts to where the

clip points draw into the belting and the

smooth edge of the clips is in contact with

the belting.

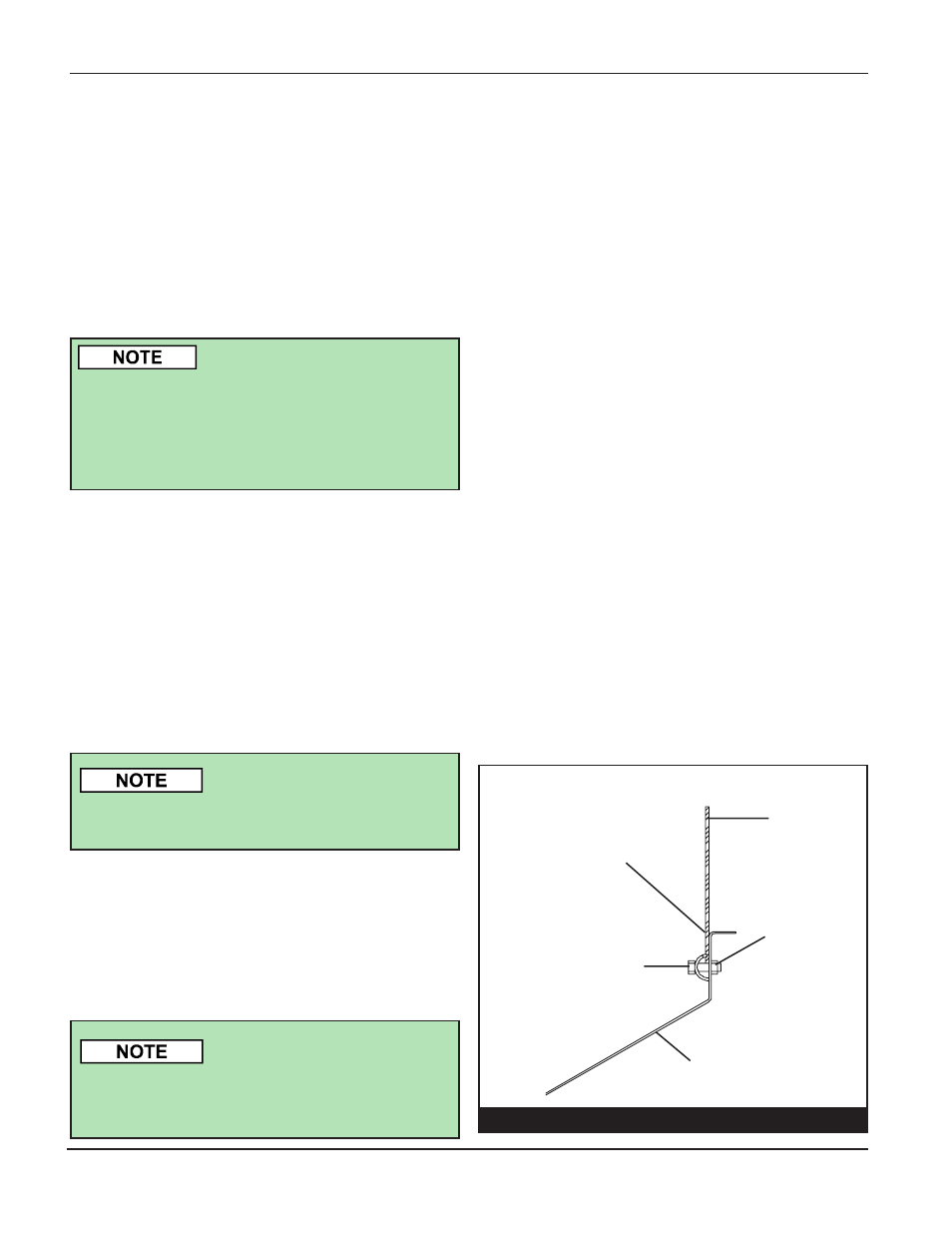

A. Install the hopper wheels to the hopper using

four (4) 5/8" x 9-3/4" long clevis pins, four (4)

wheel spacer bushings and four (4) 1-1/4"

cotter pins. Install the hopper wheels so the

front wheels are tilted in towards the incline

tube and the rear wheels are tilted away from

the hopper chain guard. Basically, you want

to tilt your wheels so they follow the arc made

when you move the hopper. (See detail 4-B)

Attachment Clip

Hopper

Hopper

1/4" Nylon

Locknut

1/4" x 1"

Hex Head Cap

FIGURE 4-C

Belt Hopper Detail