8" & 10" standard profile hopper assembly – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1391 User Manual

Page 14

14

Assembly

PNEG-1391 8",10", & 12" BE-SAW Augers

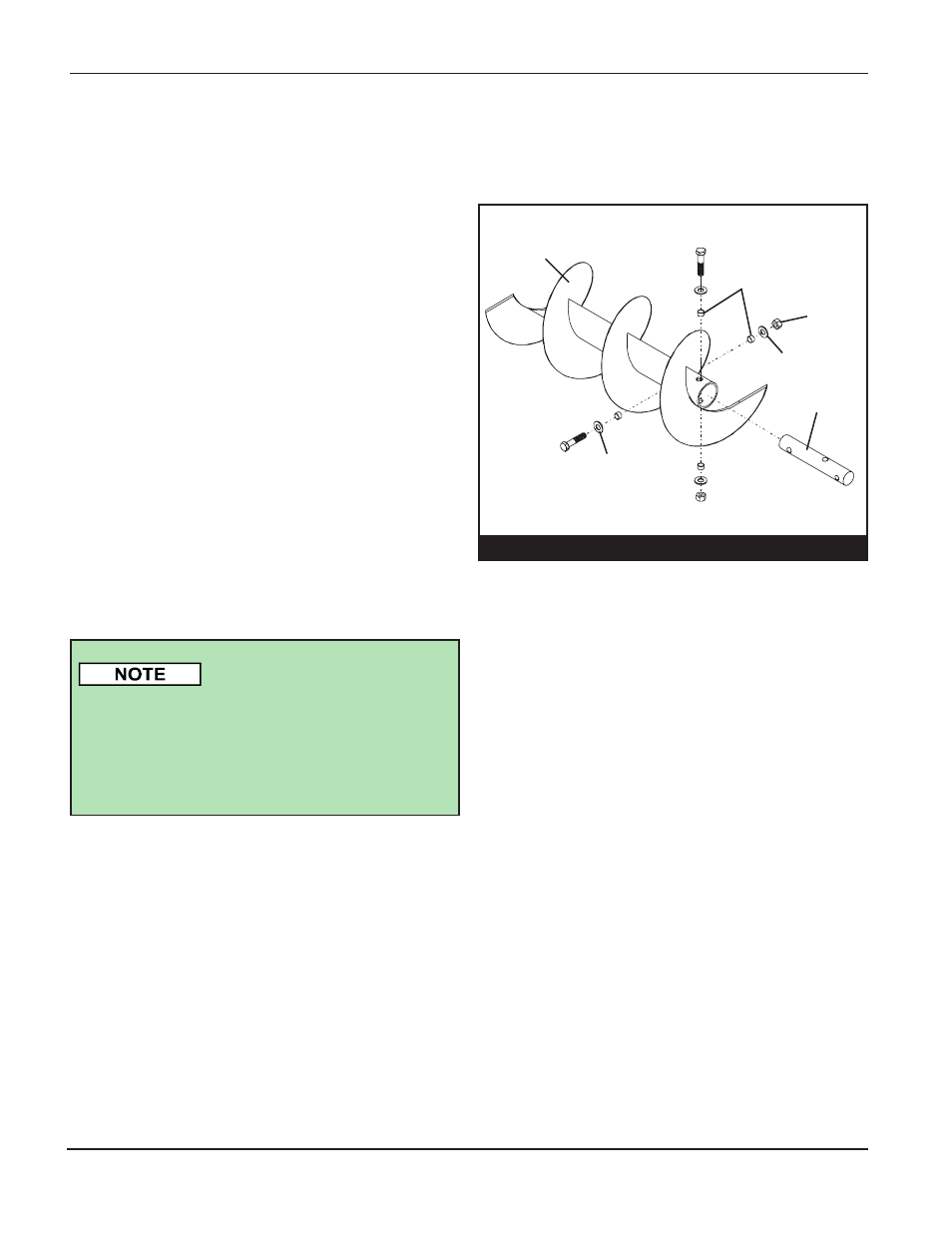

1. ASSEMBLE HOPPER 8" & 10" AND INCLINE TUBE (See Figure 1-B)

A. Apply grease to the wheel shafts of the

hopper.

B. Attach the hopper wheels to the wheel shafts

using three (3) 5/8" flat washers and one (1)

3/16" x 1-1/2" cotter pin for each wheel. Note:

One (1) to two (2) washers should be used

as spacers between the hopper and the

wheel. Use one (1) washer between the wheel

and the cotter pin.

C. Use the following hardware to bolt the

incline tail stub into the incline flight: (See

Figure 1-A)

•

Four (4) rubber sleeves

•

Two (2) hex head (Grade 5) cap screws:

For 8" models, use 3/8" x 3" long cap

screws. For 10" models, use 7/16" x

3-1/2" long cap screws.

•

Four (4) flat washers

IMPORTANT: When tighten-

ing nylon locknuts, make

sure they are firmly secured

against the rubber sleeves,

but not so tight that they lay

against the flight tube.

Leave a gap of approxi-

mately 1/16".

Nylon

Locknut

Incline

Flight

Rubber Sleeve

Flat

Washer

Tail Stub

Flat

Washer

FIGURE 1-A

Flight Connections

D. Attach the u-joint to the incline tail stub using

one (1) hex head cap screw and nylon locknut.

For 8" models, use a 5/16" x 2-1/2" long

(Grade 5) hex head cap screw. For 10"

models, use a 3/8" x 3" long (Grade 5) hex

head cap screw.

E. Attach the u-joint to the bearing stub in the

hopper using one (1) hex head cap screw and

nylon locknut. For 8" models, use a

5/16" x 2-1/2" long (Grade 5) hex head cap

screw. For 10" models, use a 3/8" x 3" long

(Grade 5) hex head cap screw.

Note: Loosen the hanger bearing hardware

for later adjustment.

8" & 10" Standard Profile Hopper Assembly