12" standard profile hopper assembly – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1391 User Manual

Page 16

16

Assembly

PNEG-1391 8",10", & 12" BE-SAW Augers

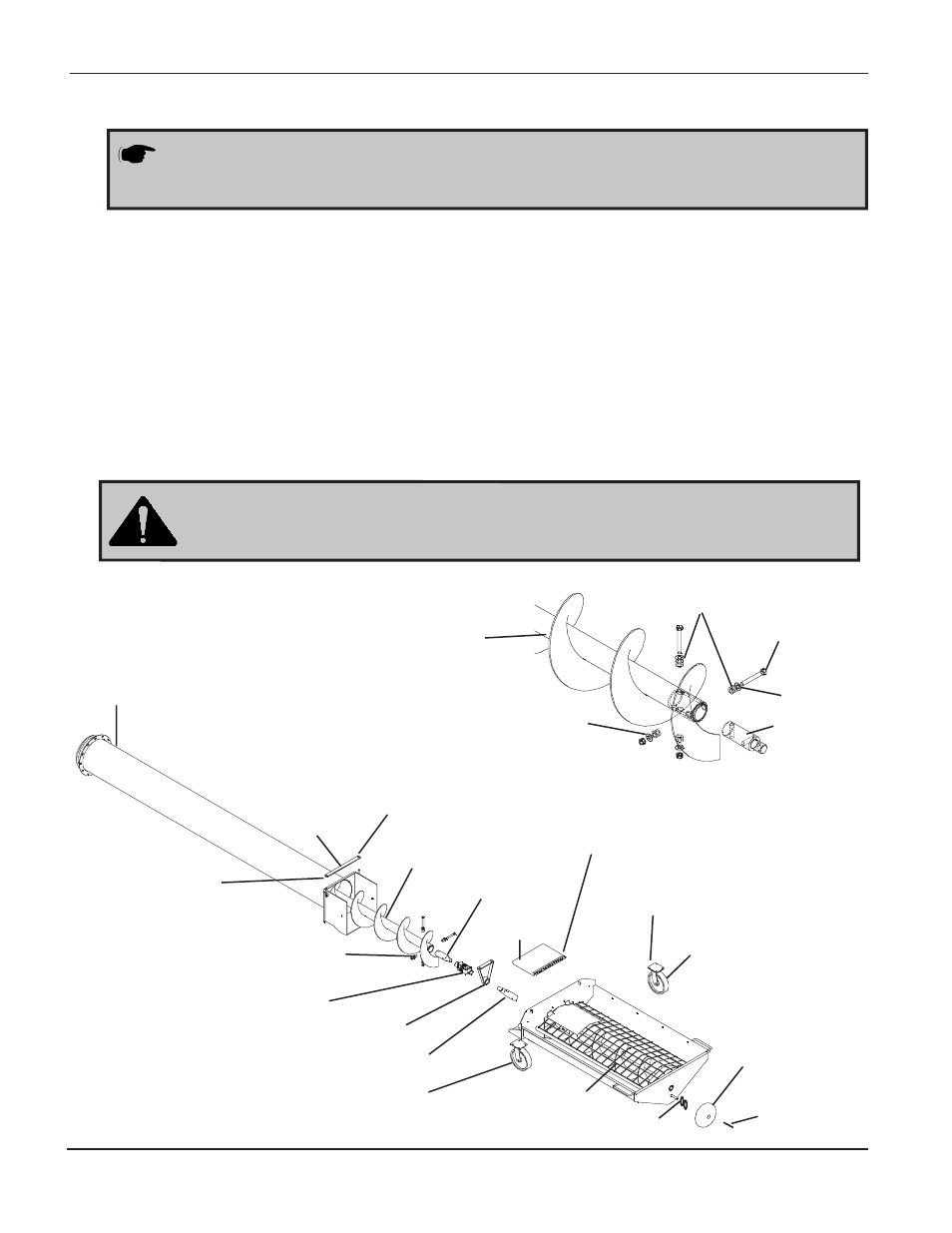

12" Standard Profile Hopper Assembly

A. Attach the rubber hopper wheel to the back of

the swing-away hopper using two (2) 5/8" flat

washers and 3/16" x 2" cotter pins. (See Fig.

2-B)

B. Fasten two (2) hopper caster wheels to front of

hopper using (4) 3/8" x 1-1/4" long (grade 5) hex

head capscrews and nylon locknuts for each

wheel.

FIG. 2-B

The hopper hanger bearing and bearing stub are pre-assembled on the swing-

away hopper. Therefore, in the drawings, those parts were exploded away from

the hopper to better show the proper assembly of the other components.

Tighten locknuts so the flat washers are firmly against the rubber sleeves.

DO NOT tighten so tight that the flat washers are against the flight tube.

Leave about 1/16" gap.

INCLINE

FLIGHT

RUBBER

SLEEVE

LOCKNUT

FLAT

WASHER

TAIL STUB

FLAT WASHER

INCLINE TUBE

5/8" X 1 1/4" LONG

(GRADE 5) HEX HEAD

CAPSCREW WITH

FLATWASHWER AND

NYLON LOCKNUTS

NOTE: INSTALL SO

BOLT HEADS ARE ON

THE INSIDE

COVER

STRAP

3/8" LOCKNUT

INCLINE

FLIGHT

TAIL STUB

HINGED

COVER

RUBBER SLEEVE

U-JOINT

BEARING STUB

BEARING HANGER

CASTER WHEEL

HOPPER FLIGHT

(2) FLAT

WASHERS

3/16" X 2"

LONG

COTTER

PIN

HOPPER

WHEEL

5/16" X 3/4" LONG (GRADE 5)

HEX HEAD CAPSCREWS,

FLATWASHERS AND NYLON

LOCKNUTS

3/8" X 1 1/4" LONG (GRADE 5)

HEX HEAD CAPSCREW AND

NYLON LOCKNUTS

CASTER

WHEEL

C. Remove the incline flight from the incline tube.

D. Attach lower end of the incline tube to the front of

the swing-away hopper. Use two (2) 5/8" x

1-1/4" long (grade 5) hex head capscrews, flat

washers, and locknuts.

E. Connect incline tail stub into the incline flight using

four (4) rubber sleeves, two (2) 1/2" x

3-3/4" long (grade 5) hex head capscrews, flat

washers, and nylon locknuts. (See Fig. 2-A)

FIG. 2-A

2. ASSEMBLE 12” HOPPER AND INCLINE

TUBE ASSEMBLY