Motors, Chapter 5 motors, Electric drive motors – Grain Systems Unload Augers PNEG-1430 User Manual

Page 20

20

PNEG-1430 6"-6", 6"-8", 8"-8", 8"-10" and 10"-12" 25° Bin Unloader

5. Motors

Electric Drive Motors

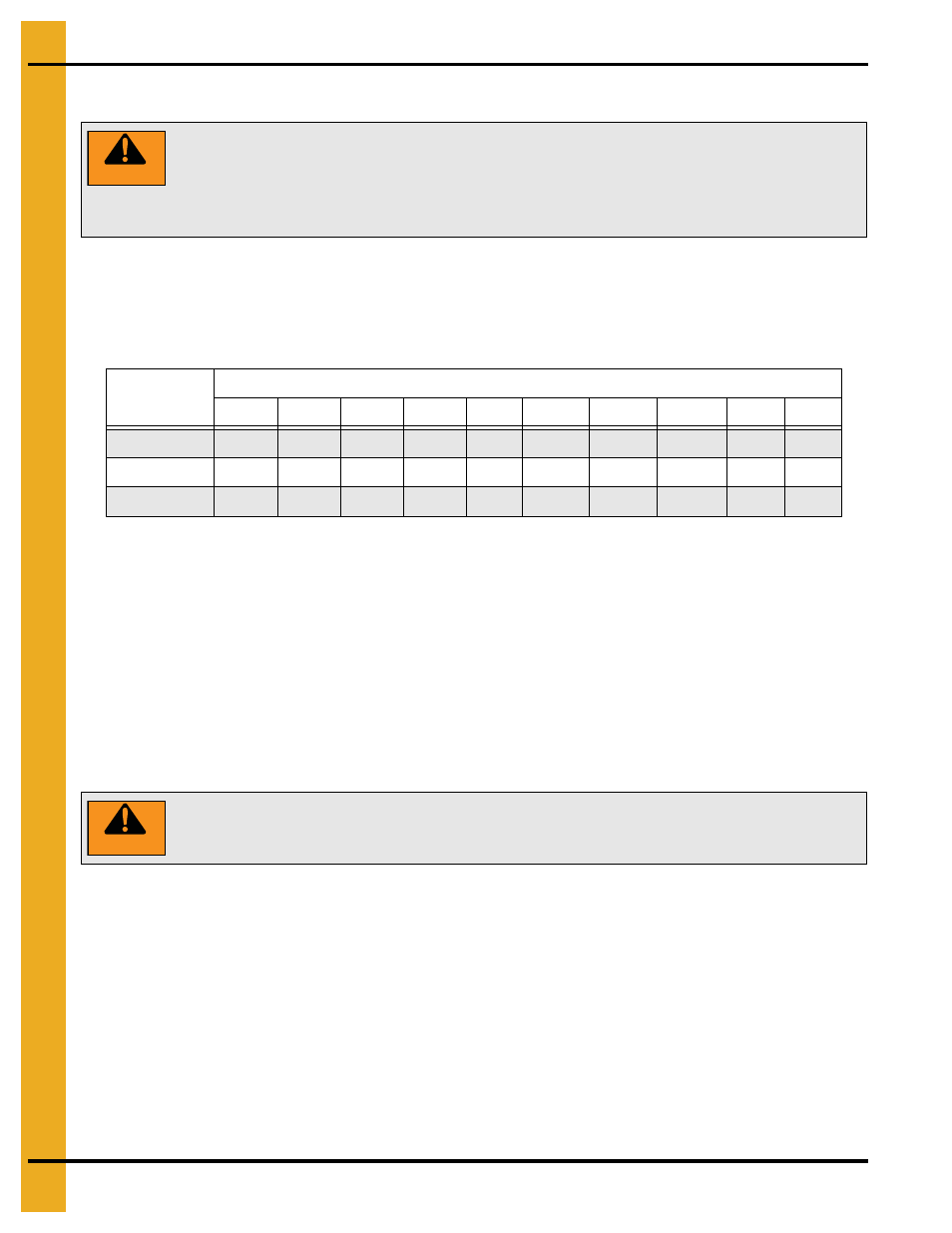

A. Knowing the bin size and the length of flighting to be used in the unloading tube is necessary to

determine how much horsepower is required for the job.

B. Use the

to determine the size of motor required. Use a larger motor when encountering

high moisture or when high capacity is required.

NOTE: For high capacity or high moisture, use one size larger motor.

LONGER BELT NOTE: Longer belts may be required when using larger framed motors due to high

capacity or high moisture applications.

C. The following horsepower recommendations are for augering relatively dry grain. Use an electric

motor of the proper size that operates at 1750 RPM. Motor pulleys are not furnished with the auger.

D. A magnetic starter should be used for the operator’s protection and for the protection of the motor.

This helps to protect the operator against accidental re-start caused by power interruption, conductor

fault, low voltage, circuit interruption or motor overload. Therefore, the motor must be restarted

manually. If using a motor with built-in thermal overload protection, make sure this type of motor has

a manual reset.

25°

Horsepower

Grain Bin Diameter

15'

18'

21'

24'

27'

30'

33'

36'

42'

48'

6"

2

2

3

3

3

3

5

5

-

-

8"

3

3

5

5

5

7-1/2

7-1/2

7-1/2

7-1/2

7-1/2

10"

-

-

-

5

5

7-1/2

7-1/2

7-1/2

10

10

WARNING

Electrical controls and wiring should be installed by a qualified electrician. The

motor disconnect switches and conductor cables should comply with the

National Electrical Code and any local codes which apply. Reset and motor

starting stations should be located so that the operator can see that all personnel

are clear of the equipment.

WARNING

Disconnect and lock out power before resetting motor overloads. Make certain

electric motors are grounded.