Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1056 User Manual

Page 23

- 23 -

Take-up rod should have one welded nut already in place. Place another nut on rod and insert

into take-up anchor. Place two nuts onto take-up rod and insert into take-up bearing weldment.

Finish by placing nut with pre-drilled hole on rod, place roll pin through nut and rod.

Attach discharge transition weldment to head side panels using 3/8”hex head bolts and 3/8”

whiz nuts. Then attach discharge transition splice plate between head bottom panel and

discharge transition. If a bottom liner is specified, a spacer between the head bottom panel and

the discharge transition splice is furnished, and should be properly positioned between these two

components before fasteners are inserted.

Center sprocket between head side panels and tighten all setscrews.

Place cover assembly on top of conveyor and fasten with 3/8” hex head bolts and 3/8” whiz

nuts.

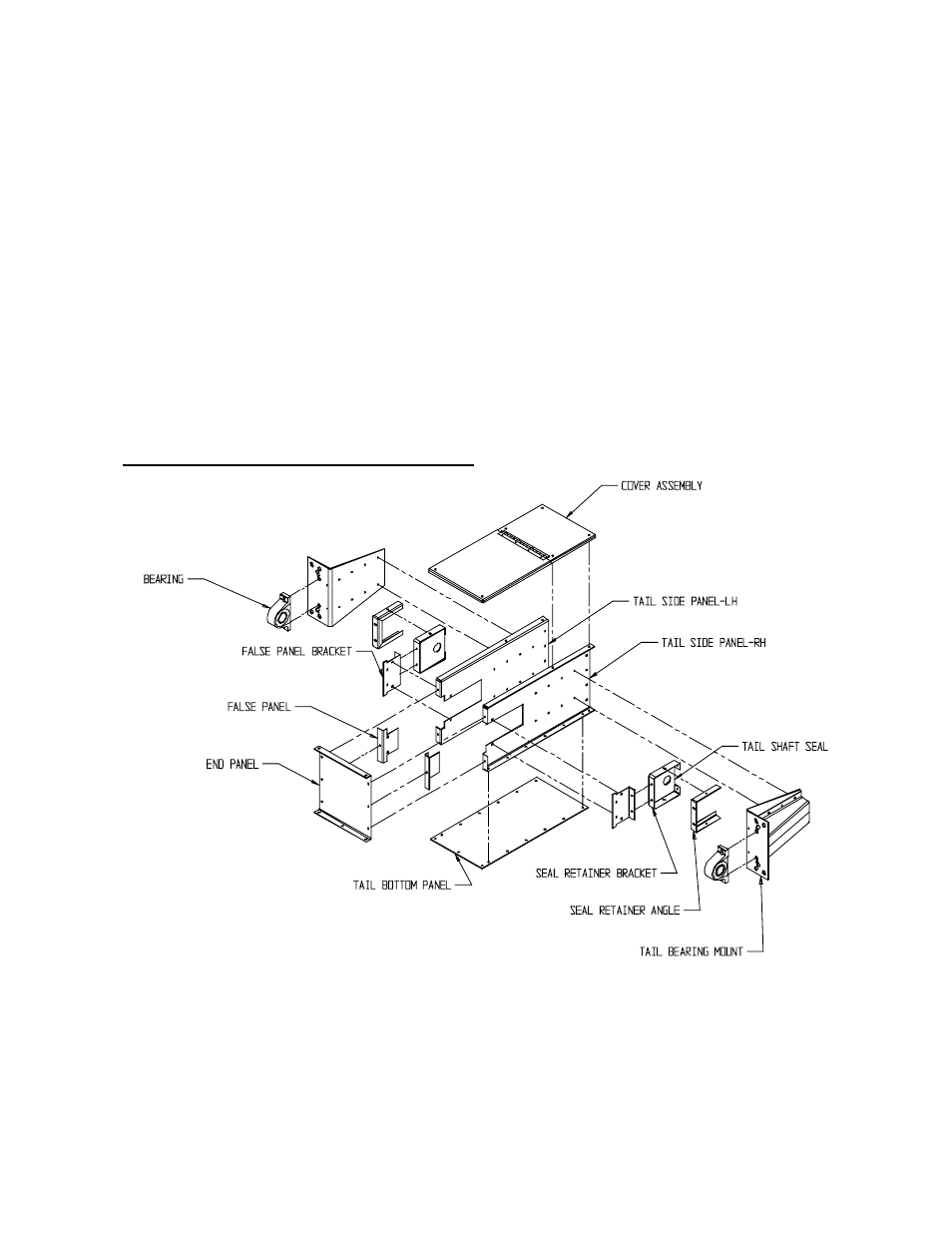

Incline ConveyorTail Section Sub-Assembly

Assembly sequence for incline tail section sub-assembly.

Fasten tail bottom panel to each tail side panel using 3/8” hex head bolts and 3/8” whiz nuts.

Whiz nuts should be located on bottom side of conveyor. The tail bottom panel should be

recessed approximately two inches.