Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1056 User Manual

Page 15

- 15 -

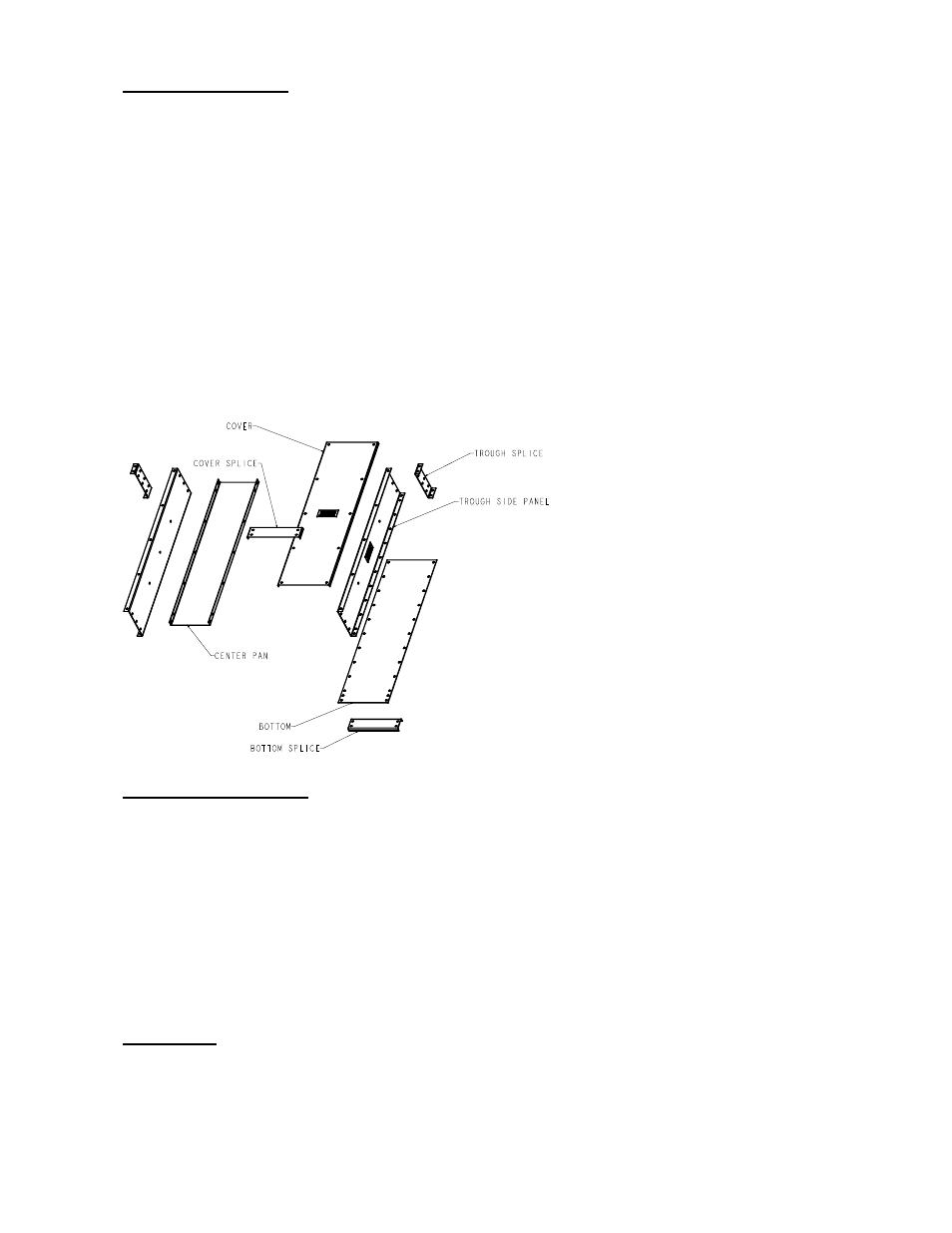

Trough Assembly

Intermediate trough sections come both factory pre-assembled or unassembled. Your order

will serve as a reference to how your trough section should arrive.

Assembly sequence for trough sections unassembled:

Fasten trough bottom panel to each trough side panel using 3/8” hex head bolts and 3/8” whiz

nuts. Whiz nuts should be located on bottom side of conveyor. The trough bottom panel should

extend beyond trough side panels approximately two inches on one end and recessed

approximately two inches on the other end.

Fasten center pan, with flange up, using 3/8” carriage bolts through holes provided in trough

side panels. At the seams the carriage bolts below the center pan should be welded to the trough

side panels. Heads of carriage bolts should be inside the conveyor. For liner package assembly

check options portion of this manual.

Conveyor Assembly

Remove trough covers from trough sections to aid the conveyor assembly.

Position a head, tail or other intermediate trough section with holes in bottom flange of trough

sides aligned with holes in bottom panel of another section. Using a bottom splice, (4) 3/8” bolts

and (4) 3/8” whiz nuts fasten the two sections together. The bottom splice should cover the gap

between the two bottom panels, which is offset two inches from the gap in the trough sides.

Position trough splices over the gap between the end of the trough sections and fasten with 3/8”

carriage bolts and 3/8” whiz nuts.

Discharge

The standard conveyor is constructed with one discharge located at the drive end.

Attach the

discharge transition to the bottom of the conveyor head using 3/8” bolts and 3/8” whiz nuts.