Cementing procedure outlet holes, Once, Cementing procedure – Grain Systems Bin Accessories PNEG-914 User Manual

Page 22: Outlet holes, Installation

5. Installation

22

PNEG-914 Flex-Flo

Cementing Procedure

Flex-Flo Systems have specially formulated PVC tubing. For strong tube connections, apply the PVC

solvent cement per the instructions as follows:

1. Square tube ends and remove all burrs and dirt.

2. Check dry fit of tubes. The smaller end of the first tube should easily slide one-third of the way into

the belled end of the second tube. The first tube end should be snug in the second tube once it is all

the way in.

3. When the temperature is below 40°F (4°C) or above 85°F (29°C), consult PVC solvent

cement container.

4. Apply a liberal coat of cement in the belled end. Avoid puddling inside.

5. Apply a liberal coat of cement on the smaller end, leaving no voids.

6. Assemble parts quickly. CEMENT MUST BE FLUID. If not fluid, re-coat both parts.

7. Push the smaller end into the belled end using a quarter turning motion until the small end bottoms.

8. Hold tubes together for 30 seconds, wipe off excess cement with cloth. Completed joints should not

be disturbed until they have cured enough to withstand handling.

Keep container closed when not in use.

Outlet Holes

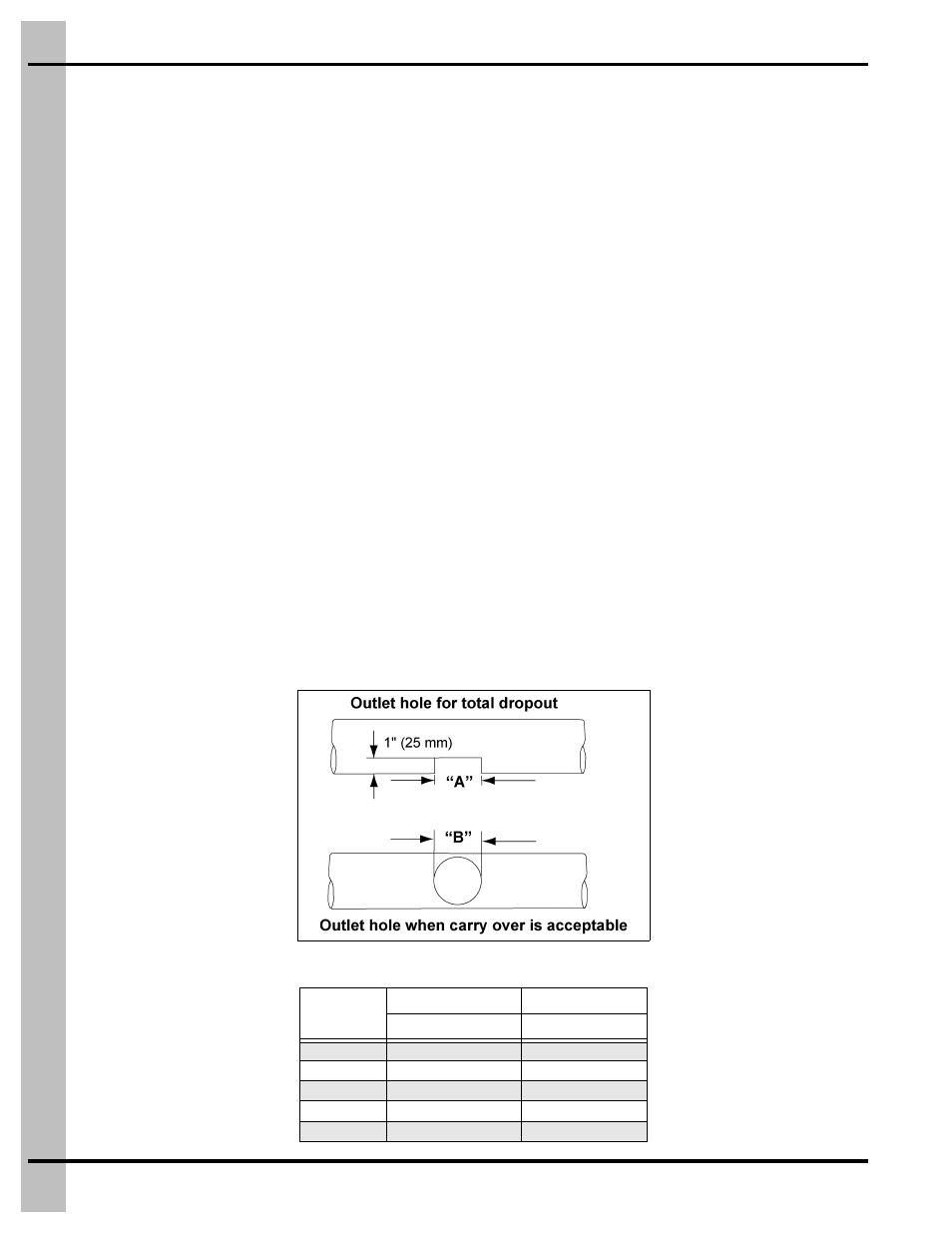

Establish where the outlet drops are to be. Once this is done, cut holes for the outlet drops.

for hole size recommendations. If total drop-out is necessary, it is recommended that the holes are cut using

a saber saw or hacksaw. When carry-over is desired, it is recommended that the outlet holes are cut with

a holesaw.

Figure 5L Outlet Hole Cutting Chart

Model

Full Drop

Carry-over

Variable “A”

Variable “B”

220

1-1/2'' (38 mm)

1-1/2'' (38 mm)

300

2-1/2'' (63 mm)

2-1/2'' (63 mm)

350

3'' (76 mm)

3'' (76 mm)

500

4'' (102 mm)

4'' (102 mm)

HR

3'' (76 mm)

2-1/2'' (63 mm)