Flex-flo specifications (english/metric), Chapter 4, The feed tank connections – Grain Systems Bin Accessories PNEG-914 User Manual

Page 11: Feed tank orientation, Flex-flo systems specifications

PNEG-914 Flex-Flo

11

4. Flex-Flo Specifications (English/Metric)

Flex-Flo Systems Specifications

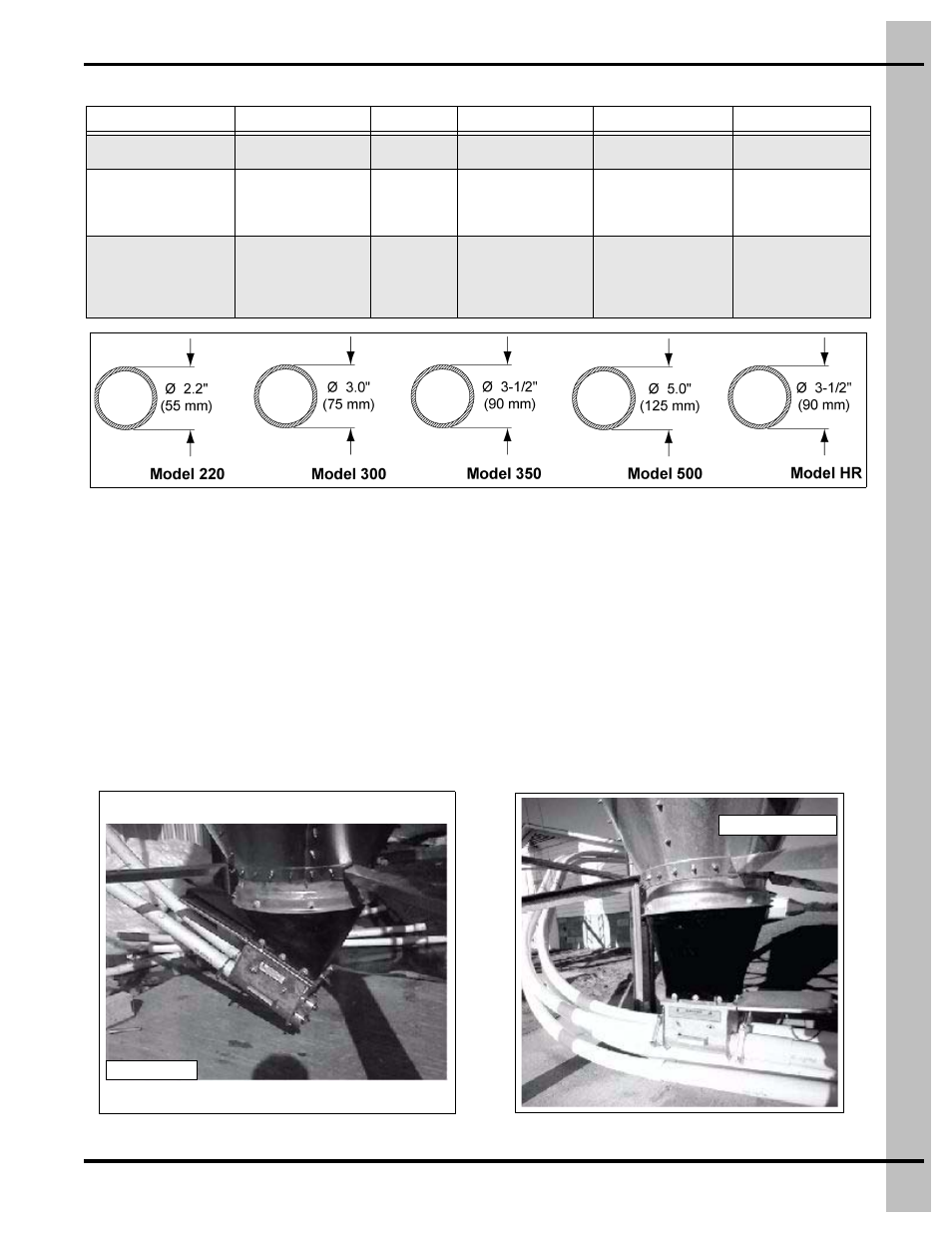

Figure 4A

The Feed Tank Connections

Feed Tank Orientation

Positioning the feed tank in line with the Flex-Flo System will provide the most trouble-free operation possible.

Avoid unnecessary elbows and curves to ease system installation. A feed tank with a 30° unloader is

generally required to be at least 10-1/2' (3.2 m) away from the building. With a straight unloader, the tank

will be approximately 4' (1.22 m) farther away from the building in order to make auger tube connections.

The reference points are based upon the height where the system enters the building. Different unloaders

with various elbows and curves used provide different entrance opportunities. The distances are achieved

by modifying and adjusting the elbows and tubing as needed. See tables

(English) or see tables

(Metric) for tank placement recommendations.

Figure 4B

Figure 4C

Model 220

Model 300

Model 350

Model 500

Model HR

Auger Tube Diameter

2.2"

55 mm

3"

75 mm

3-1/2"

90 mm

5"

125 mm

3-1/2"

90 mm

Carrying Capacity based

on 40 lbs./cubic ft.

15 lbs./min

7 kg/min

900 lbs./hr

420 kg/hr

50 lbs./min

22 kg/min

3000 lbs./hr

1400 kg/hr

100 lbs./min

45 kg/min

6000 lbs./hr

2700 kg/hr

220 lbs./min

100 kg/min

13200 lbs./hr

6000 kg/hr

50 lbs./min

22 kg/min

3000 lbs./hr

1400 kg/hr

Maximum Particle Size

and Feed Type

1/8" (3.175 mm) x

1/2" (12.7 mm) Long

Maximum Moisture

Content 18%

Crumble Type

Feed Mash

Shelled Corn or Pellets

3/16" (4.76 mm) x

1/2" (12.7 mm)

Ground Corn

Larger Feed Fragments

Like Shelled Corn or

Pellets 3/8" (9.52 mm) x

1" (25.4 mm) Long

High Moisture Shelled

Corn (up to 27%) or

Ground Feed. 3/8"

(9.52 mm) Diameter x

3/4" (19.05 mm) Long

30° Unloader

Straight unloader