Auger tubing installation (continued), Installation – Grain Systems Bin Accessories PNEG-914 User Manual

Page 21

5. Installation

PNEG-914 Flex-Flo

21

Auger Tubing Installation (Continued)

5. Remove the non-belled end of the straight tubing from the “building” elbow. Slide the belled end of

the straight tubing over the freshly cut end of the “unloader” elbow. Mark and cut the straight tubing

(as needed) so that it will fit inside the belled end of the “building” elbow.

6. Dry fit all of the outside tubing to ensure correct installation. Once satisfied, glue or clamp the tubing

together as per the instructions in the section titled cementing procedure

7. When the auger tubing between the unloader and the building is 15' (4.57 m) or longer, the tubes

should be supported.

8. Locate and cut the outlet holes needed in the remaining straight tubes. For the exact size of outlet

holes, see section titled outlet holes

. Once ALL of the outlet holes are made and the

tubing is dry fitted, glue or clamp the tubes together per the instructions in the section entitled

cementing procedure

.

9. Suspend the auger tubes and elbows from the ceiling at least once every four feet (4'). If horizontal

elbows are used, support them in at least two (2) places. Chain and lag screws are provided in each

suspension kit. The tubes should be kept as straight and level as possible.

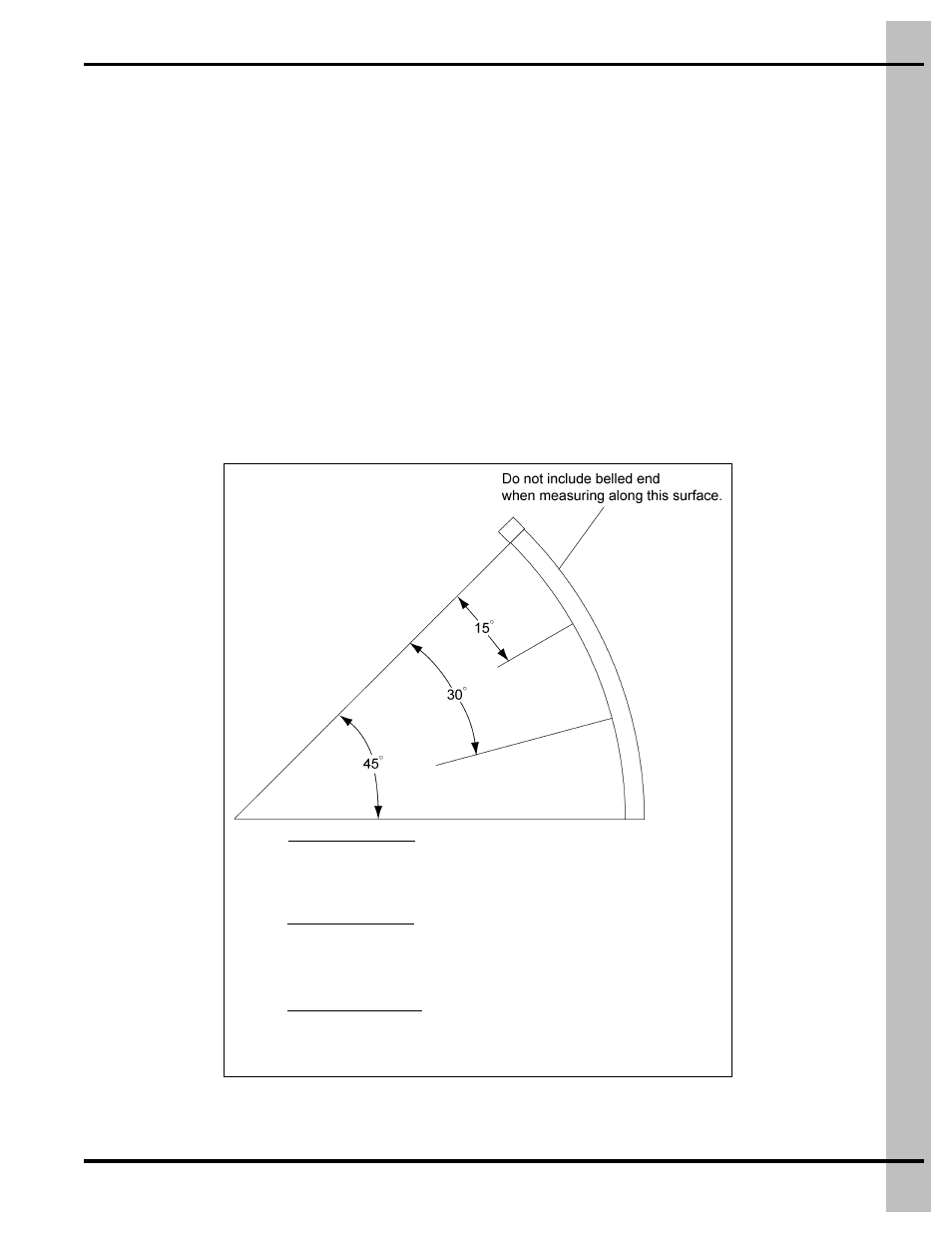

Figure 5K Cutting Chart for 45° Elbow

NOTE: Align all outlet holes in proper functional positions prior to gluing the tube joints together.

5' (1.524 m) Radius

15° Elbow - 15-3/4" (40.005 cm)

45° Elbow - 47-1/4" (120.015 cm)

30° Elbow - 31-1/2" (80.01 cm)

6' (1.829 m) Radius

15° Elbow - 20-3/16" (51.276 cm)

45° Elbow - 60-1/2" (153.67 cm)

30° Elbow - 40-5/16" (102.394 cm)

10' (3.048 m) Radius

15° Elbow - 32" (81.28 cm)

45° Elbow - 96" (243.84 cm)

30° Elbow - 64" (162.56 cm)