Sidewall assembly, Chapter 7 sidewall assembly, Sidewall erection instructions – Grain Systems Tanks PNEG-1070 User Manual

Page 43: Decal sheet placement

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

43

7. Sidewall Assembly

Sidewall Erection Instructions

Before bolting the sidewall sheets together, make sure that you are using the proper gauge steel for the

first ring. The higher gauge numbers denote the thinner materials. (For example, 22 gauge material is

thinner than 14 gauge.) In erecting most grain bins the thinnest material usually goes on top, therefore the

first sidewall ring you assemble will be the top ring of the bin, usually the thinnest

gauge. Check the various

gauges of the bin with the color code chart and begin building accordingly. REMEMBER always assemble

the top ring first.

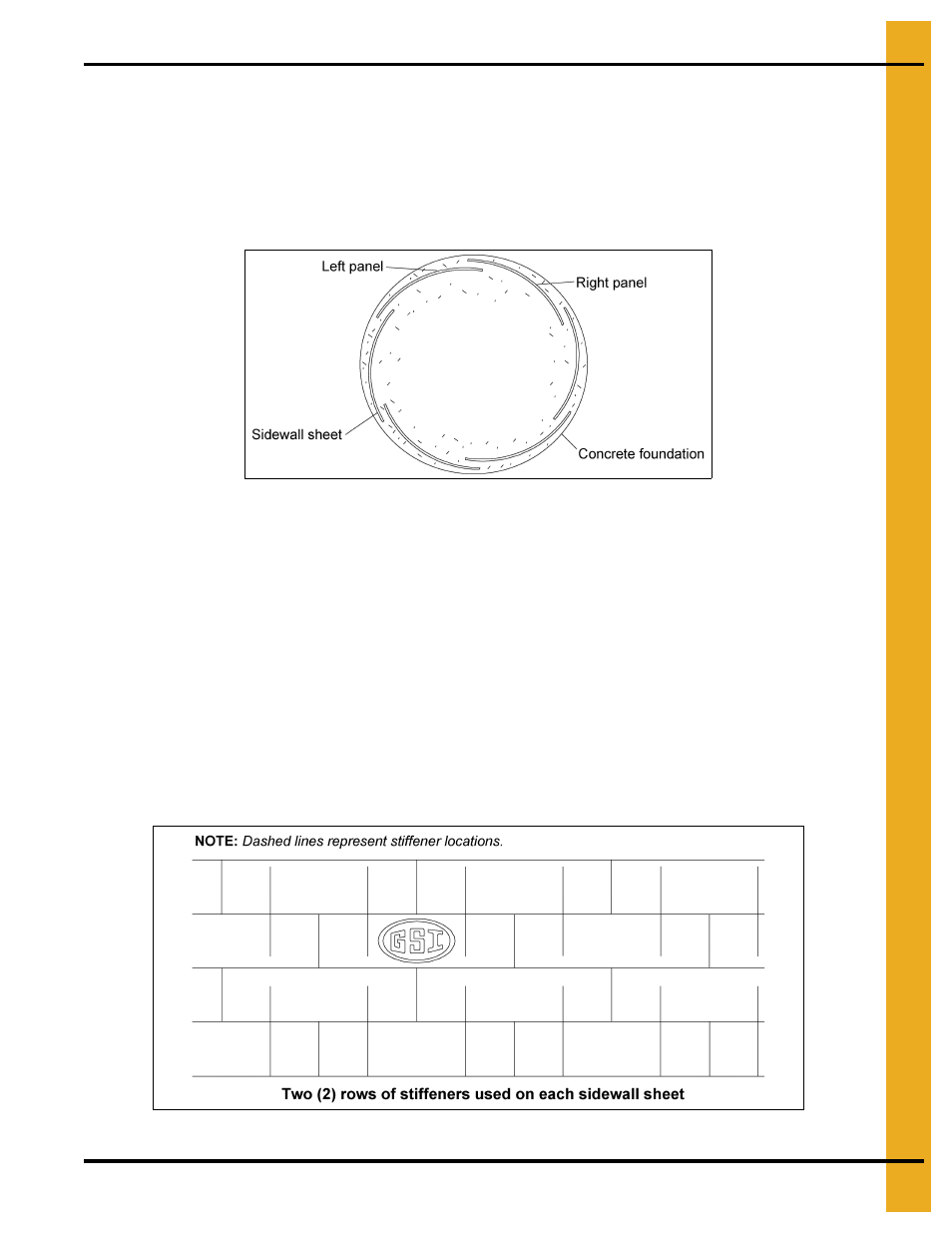

Figure 7A

Once you have selected the proper gauge material, begin assembling all sidewall sheets. Stand on the

inside the bin, place the left panel to the inside with the right panel to the outside.

NOTE: The rope caulking is installed before each sheet is assembled. Wipe sheet clean where caulking

is to be applied. Refer to

for caulking placement.

Using correct size bin bolts throughout, begin assembling sidewall sheets end to end (overlapping the

same way throughout) until the ring is completed. All body sheet bolts are to be installed with the bolt head

and its neoprene washer to the outside and the nut on the inside. Do not tighten bolts until all sheets are

assembled and form a complete ring. Lifting of sidewall should be done with jacks and lifting brackets on

the stiffener bolt holes.

Decal Sheet Placement

NOTE: The decal sheets are located in the second ring from the top, evenly spaced around the diameter

of the bin.

Figure 7B 2 Post