27'-30' hopper assembly – Grain Systems Tanks PNEG-1070 User Manual

Page 41

6. 27'-30' Hopper Assembly

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

41

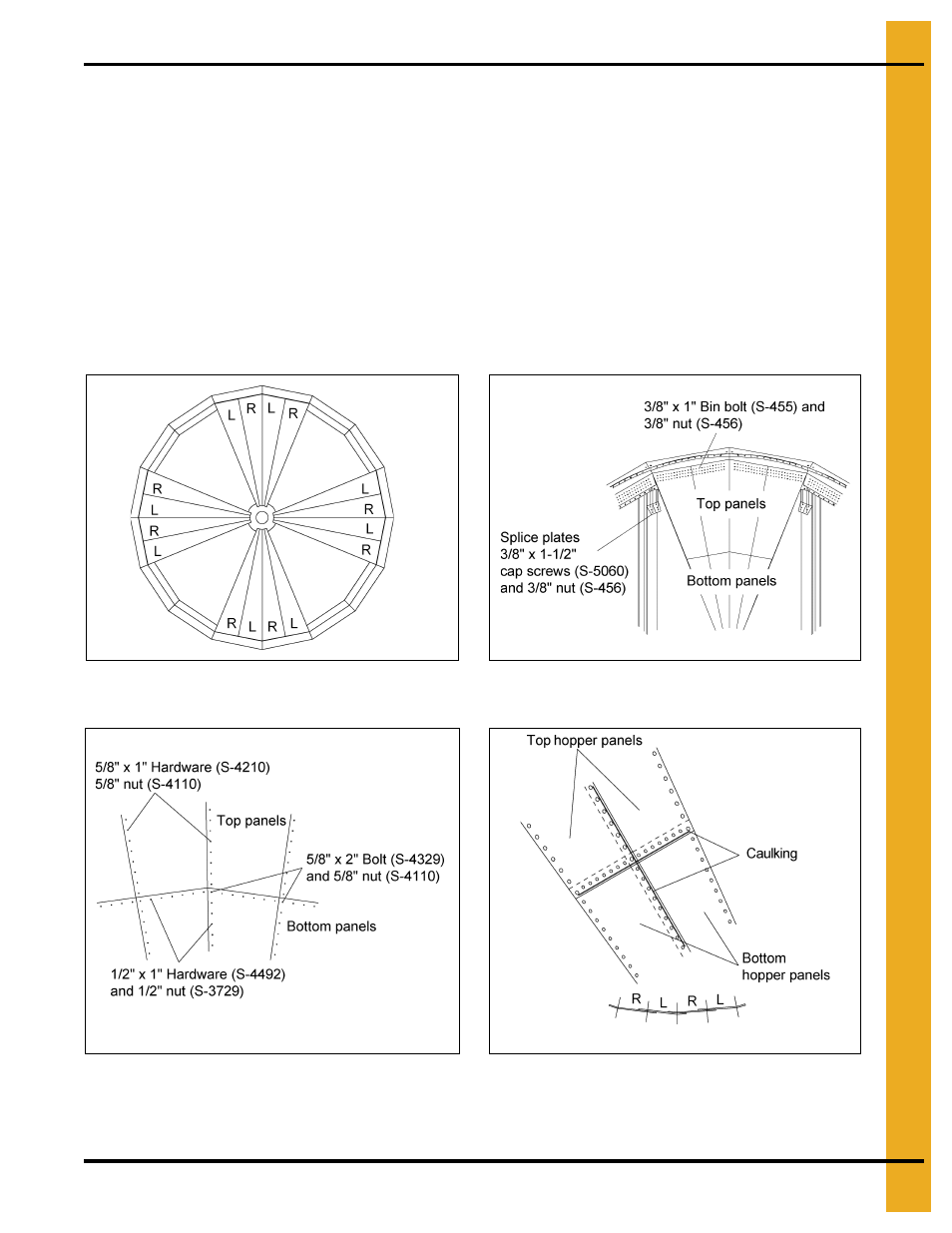

Begin assembling the two (2) piece hopper bottom by attaching a right and left pair or pairs of the top

hopper panels to the compression angle ring (3/8" x 1" bin bolts (S-455) and 3/8" nut (S-456)), along with

the back side splice plates which use (3/8" x 1-1/2" bin bolts (S-5060) and 3/8" nut (S-456)). Refer to

. All top panel seams use 5/8" x 1" hardware (S-4210) and 5/8" nut (S-4110). Once the top panels

are positioned the bottom hopper panels may be attached to the top panels and discharge collar with

1/2" x 1" hardware (S-4492) and 1/2" nut (S-3729), at four (4) opposing points as shown in

.

A 5/8" x 2" bolt (S-4329) and 5/8" nut (S-4110) is used on all corners of the spliced hopper panels. Refer

to

for bolt usage on hopper panels. Caulking is required on all vertical and horizontal seams of

the hopper bottom, (refer to

). Complete this assembly by laying in alternate right and left panels

moving around in one direction and lapping all sheets the same way. Do not tighten bolts until all hopper

panels are attached to each other, the compression ring, splice plates and discharge collar.

30' Commercial hopper tank has two (2) piece hopper as shown.

27' Commercial hopper tank has two (2) piece hopper as shown.

Figure 6D Hopper Panel and Discharge

Collar Assembly

Figure 6E Hopper Panel Bolt Usage

Figure 6F Hopper Panel Detail

Figure 6G Caulking and Lap

(Viewed from Inside of Bin)

Detail J

Detail K