Grain Systems Tanks PNEG-1070 User Manual

Page 42

6. 27'-30' Hopper Assembly

42

PNEG-1070 15', 18', 21', 24', 27' and 30' CHT’s

Start at the bottom of the hopper and tighten all bolts, including anchor bolts, discharge collar, hopper

panels, splice plates and compression angle segments.

Install rack and pinion roller gate as shown in

, using 5/16" x 3/4" hardware (S-275).

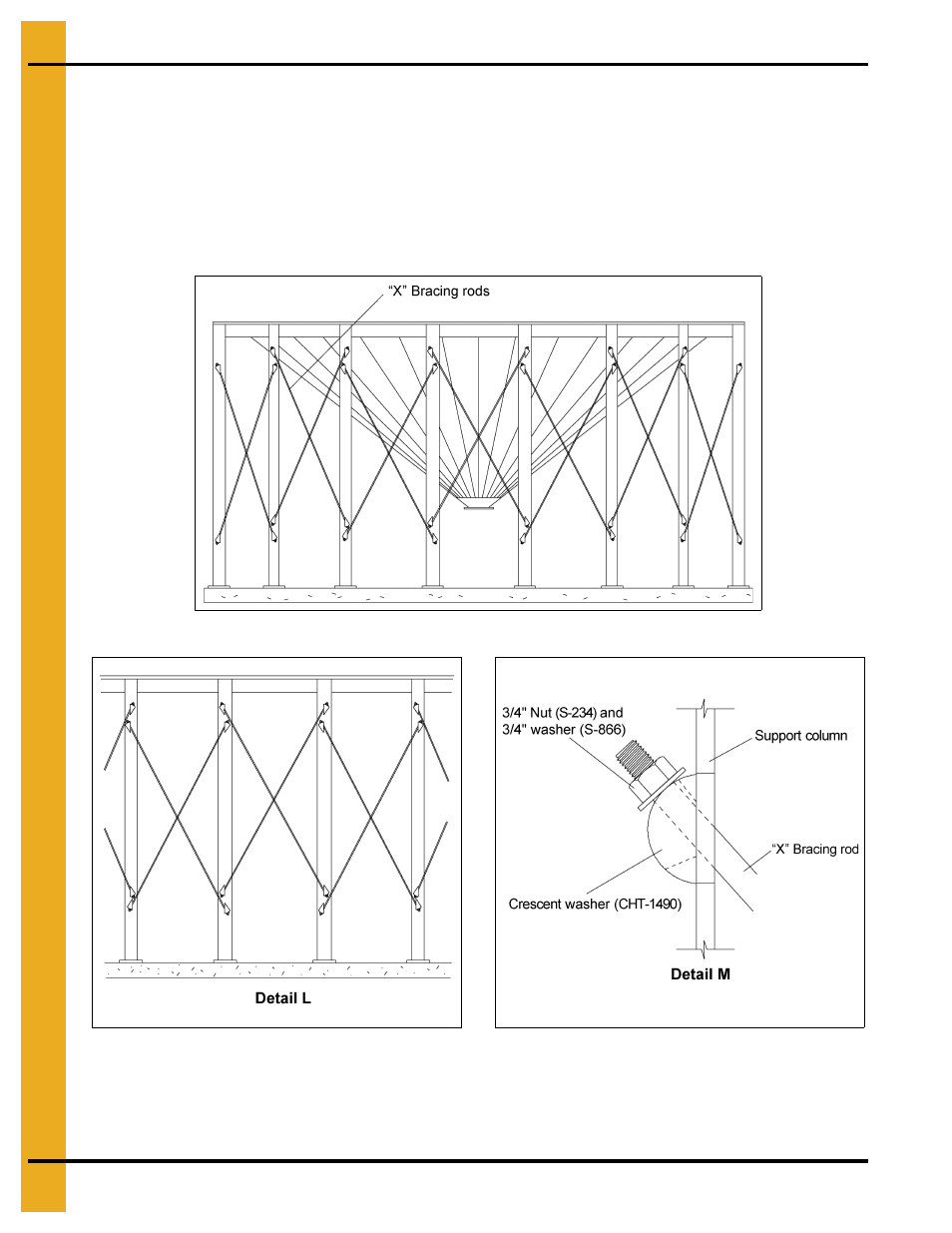

Install “X” bracing as shown in

.

When the hopper structure has been completed, it should be level to within ± 1/8" maximum deviation, as

compared to all other support columns as measured at the top of the compression angle ring. The support

columns must be plumb to within ± 1/2" as measured from top to bottom.

Figure 6H Completed Hopper Assembly

Figure 6I “X” Bracing Rods

Figure 6J

See also other documents in the category Grain Systems Equipment:

- Bin Accessories PNEG-1883 (26 pages)

- Bin Accessories PNEG-104 (2 pages)

- Bin Accessories PNEG-1859 (90 pages)

- Tanks PNEG-4075 (168 pages)

- Bin Accessories PNEG-1789 (7 pages)

- Special Roofs PNEG-1845 (28 pages)

- Unload Augers PNEG-1550 (22 pages)

- Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1842 (114 pages)

- Tanks PNEG-1784 (5 pages)

- Bin Accessories PNEG-1336D (34 pages)

- Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1618 (10 pages)

- Tanks PNEG-4072G (162 pages)

- Unload Augers PNEG-1556 (58 pages)

- Bin Accessories PNEG-268 (2 pages)

- Bin Flooring PNEG-1830 (44 pages)

- Tanks PNEG-603 (56 pages)

- Bin Flooring PNEG-1835 (48 pages)

- Bin Flooring PNEG-1816 (42 pages)

- Bin Accessories PNEG-1870 (28 pages)

- Bin Accessories PNEG-1088 (30 pages)

- Tanks PNEG-1880 (30 pages)

- Tanks PNEG-4054G (168 pages)

- Unload Augers PNEG-1583 (28 pages)

- Bin Accessories PNEG-318 (180 pages)

- Bucket Elevtors, Conveyors, Series II Sweeps PNEG-970 (36 pages)

- Bin Flooring PNEG-219 (32 pages)

- Tanks PNEG-083 (28 pages)

- Bin Flooring PNEG-1826 (42 pages)

- Bin Accessories PNEG-1802 (50 pages)

- Unload Augers PNEG-1521 (64 pages)

- Tanks PNEG-4090A (166 pages)

- Bin Accessories PNEG-1933 (2 pages)

- Bin Accessories PNEG-1496 (2 pages)

- Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1902 (7 pages)

- Bin Accessories PNEG-1177 (16 pages)

- Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1204 (59 pages)

- Bin Accessories PNEG-130 (2 pages)

- Bin Accessories PNEG-1451 (102 pages)

- Tanks PNEG-1095 (76 pages)

- Bin Accessories PNEG-1868 (26 pages)

- Bin Accessories PNEG-1840 (32 pages)

- Unload Augers PNEG-790 (18 pages)

- Tanks PNEG-1461 (124 pages)

- Bin Accessories PNEG-1884 (26 pages)

- Bin Accessories PNEG-1852 (26 pages)