Liquid propane (lp), Installation, Notice – Grain Systems PNEG-900 User Manual

Page 32

3. Installation

32

PNEG-900 Series 2000 Autoflow Fan/Heater and Control Installation Instructions

Liquid Propane (LP)

Top Dry dryers have internal vaporizers and are designed to operate on liquid draw from the supply tank.

Avoid using propane supply tanks that have been used for vapor draw for long periods of time. When using

liquid draw systems, any moisture that may be present in tanks or lines may freeze when the system is

used in cold weather. To avoid this situation, purge the system with methanol.

Because the vaporizer coil may need to be adjusted during operation flexible hose suitable for LPs should

be used for the final field connection.

See the

“Fuel Systems and Recommendations Chart” for liquid propane (LP) to determine the

correct size line to run from the tank to the dryer. Have a qualified gas service person inspect the

installation to be sure that everything is installed according to local codes and ordinances.

After installation is complete, check all connections for leaks with liquid detergent or comparable. Wear

rubber gloves and eye protection. Avoid contact with liquid propane.

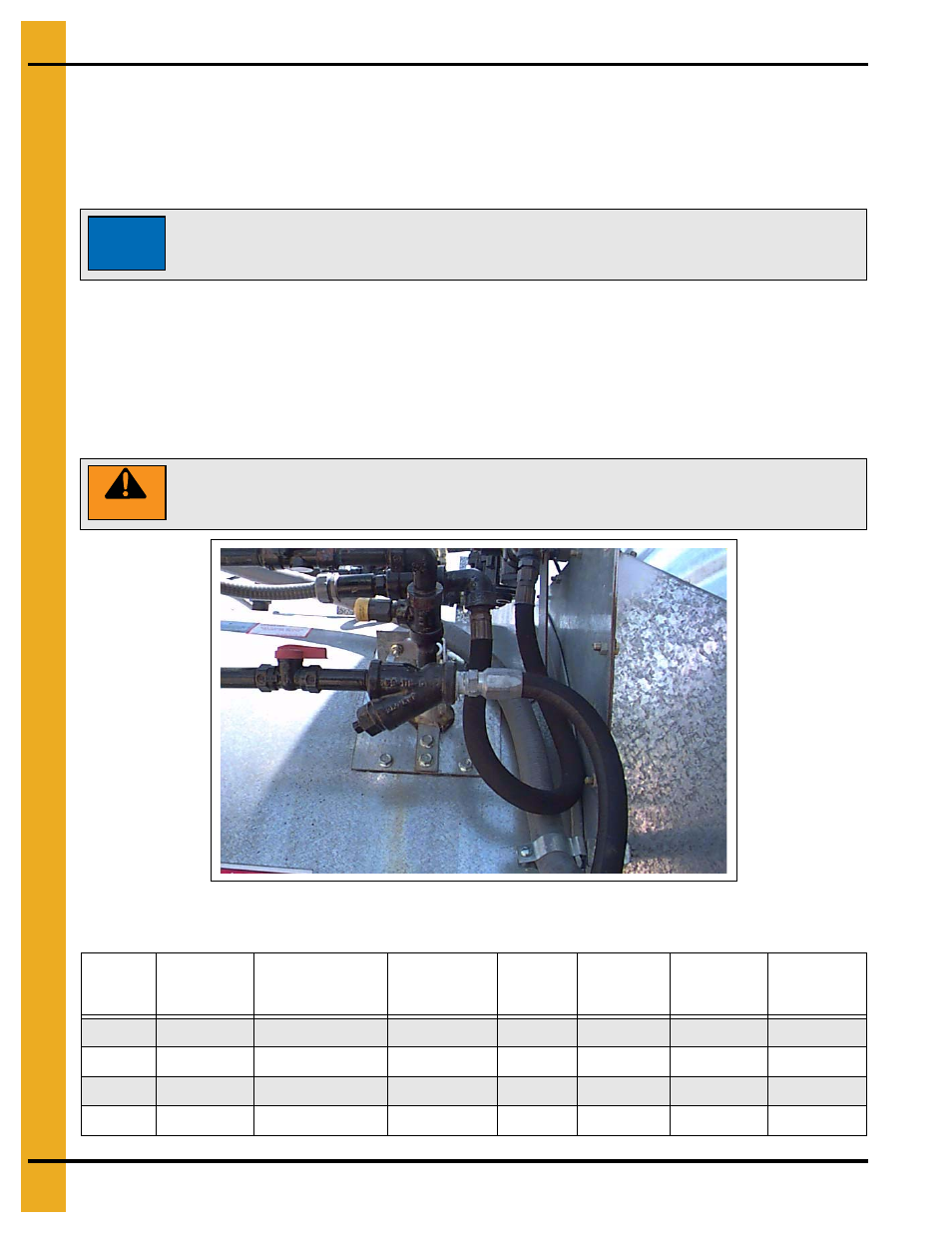

Figure 3V LP Line Field Connection

Fuel System Specifications and Recommendations Liquid Propane (LP)

Dryer

Fan Size

Dryer

Horsepower

Maximum Heat

Capacity BTU

per Hour

Maximum Fuel

Flow Gallons

per Hour

Minimum

Line Size

Orifice Size

Minimum

Operating

Pressure

Maximum

Operating

Pressure

36"

15

5 Million

54

1/2"

21/64"

1 lb.

15 lbs.

40"

15

5.5 Million

60

1/2"

11/32"

1 lb.

15 lbs.

42"

30

9 Million

95

1/2"

0.328"

1 lb.

15 lbs.

42"

40

9.5 Million

104

3/4"

29/64"

1 lb.

15 lbs.

NOTICE

Do not use tanks which have previously been used for ammonia or fertilizer

solutions. These substances are extremely corrosive and will damage fuel supply

and burner parts.

WARNING

Do not use flame for leak testing.