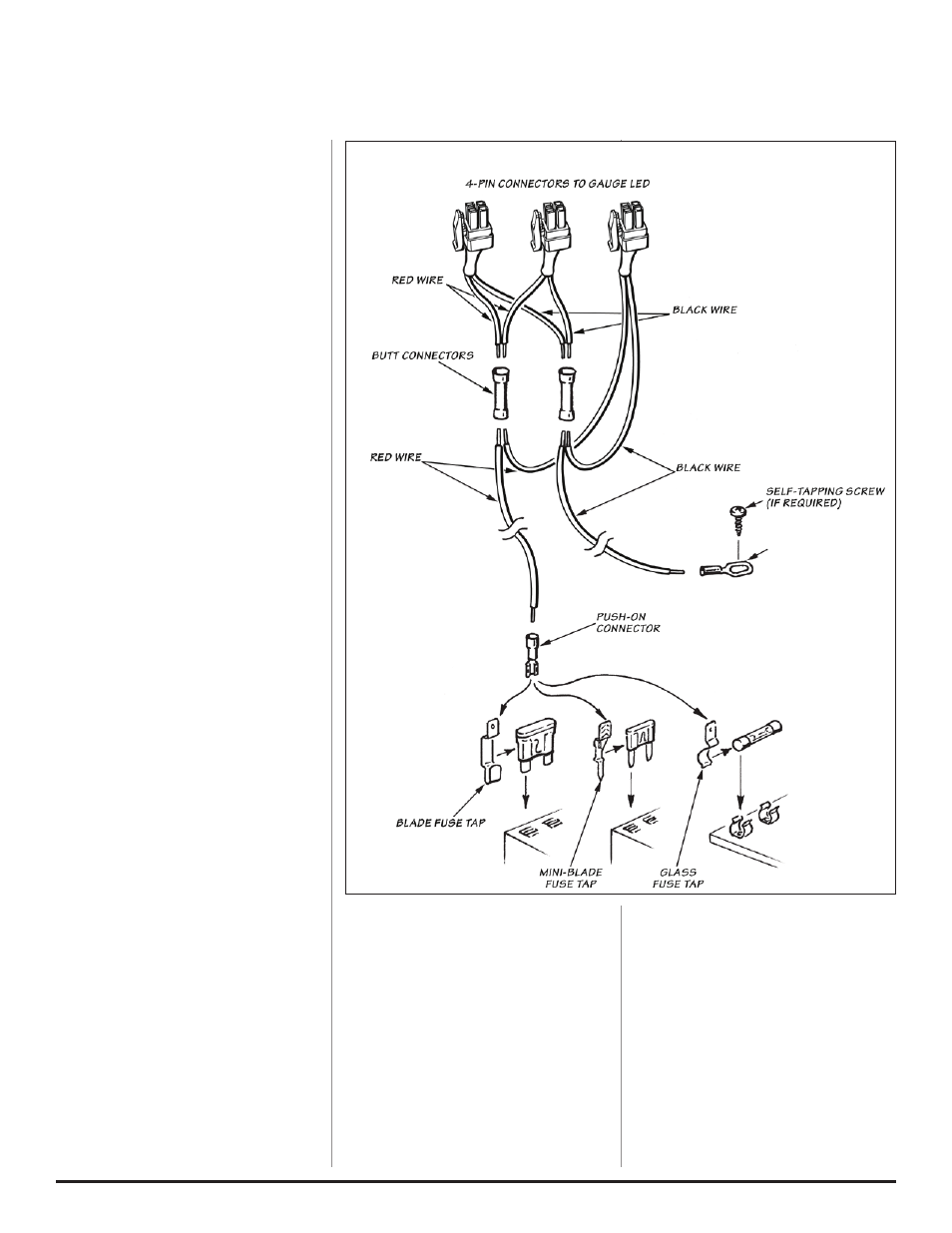

Figure 8 - gauge connections – Banks Power Ford Trucks: (Diesel ’99 - 03 7.3L Power Stroke) Power Systems- PowerPack, Stinger-Plus, Stinger & Git-Kit '19991_2-2003 F-250 & F-350 Trucks and Excursions User Manual

Page 17

96336 v.10.0

17

9.

Install one

1

⁄

8

” NPT female by

1

⁄

8

”

compression 90° fitting onto the

threaded end of the tee. Sparingly apply

pipe sealant tape or paste on the male

pipe threads, and adjust the 90° fitting

to point back toward the firewall, as

shown in Figure 7. Do not allow any

sealant to cover the small hole in the

fitting. Do not over-tighten the plastic

fitting.

10.

Install one end of the

1

⁄

8

”-diameter

plastic tube provided into the

compression fitting on the plastic tee or

the fitting on the compressor discharge

elbow (PowerPacks only) and tighten

the nut. Be sure the plastic tube cannot

be pulled out of the ferrule, but do not

over-tighten the nut.

11.

Route the free end of the tube up

and along the top of the firewall toward

the brake master cylinder assembly.

Use caution to avoid kinks in the line.

Tie the tube to existing wires and hoses

with the cable ties provided. Follow

the routing of the pyrometer lead-wire

through the firewall.

12.

Route the plastic tube to the gauge

panel and cut the tube to the proper

length. Install the gauge through the

panel or console using the U-clamp and

two hex nuts provided with the gauge.

13.

Install the 90° elbow fitting onto

the connection at the back of the gauge.

Use Teflon thread sealer on the male

threads of the gauge nipple. Do not

allow any sealant to cover the pin-sized

hole in the end of the gauge nipple.

14.

Insert the tube into the nut and

ferrule on the adapter fitting at the

gauge, then tighten the nut against the

tube and ferrule. Do not over-tighten.

15.

Connect the 4-pin connector

of each gauge into the back of its

corresponding gauge.

a. Crimp the remaining Black and RED

wires from each 4-pin connector gauge

harness to the butt connectors as

shown in Figure 8.

b. Strip one end of the RED wire and

crimp it to the butt connector

containing the RED wires from step

‘a’.

c. Strip one end of the BLACK wire

and crimp it to the butt connector

containing the BLACK wires from step

‘a’.

d. Route the RED wire to the fuse box.

Locate the appropriate fuse for

instrument lighting in the owner’s

manual. Cut the RED wire as required

and strip the end. Crimp the push

on connector to the RED wire and

connect to the fuse as shown in

Figure 8. Alternatively, locate power

wire to dimmer switch and install

T-tap. Cut the RED wire as required

and strip the end. Crimp the push on

T-tap connector to the RED wire and

connect to T-tap on dimmer power

wire.

e. Locate a metal surface that will serve

as an acceptable chassis ground. Cut

the BLACK wire to a sufficient length

that will allow it to reach the chassis

ground and strip the end. Crimp the

ring terminal to the BLACK wire as

shown in Figure 8.

f. Drill a

1

⁄

8

” hole, if required, to attach

the ring terminal to the chassis

ground.

CAuTIoN: If drilling, check the

backside to make sure there are no

components that may be damaged

by drilling.

g. Use the supplied self-tapping screw to

secure the ring terminal to the chassis

ground.

NOTE: On vehicles with an automatic

transmission, complete the

TransCommand installation before

proceeding.

–END, SECTION 8–

Figure 8- Gauge Connections