Banks Power Ford Trucks: (Diesel ’94 - 97 7.3L Power Stroke) Power Systems- PowerPack, Stinger-Plus & Stinger '94-98 4" Exhaust User Manual

Page 7

For Stinger system, proceed to

Section 3

1.

loosen the clamps holding the

air intake hose to the turbocharger

compressor inlet and the aluminum

air intake casting. remove the hose.

see Figure 2.

2.

Disengage the exhaust

backpressure control actuator rod by

sliding the cover on the end of the

rod back toward the turbocharger

and pulling the rod downward.

3.

loosen the four clamps on the

compressor discharge plenum

hoses and the clamp attaching the

plenum to the compressor. Pull the

compressor discharge plenum up off

the engine. remove the o-ring that

seals the compressor outlet to the

plenum.

4.

At the rear of the turbine housing,

remove the two bolts at the top and

the two nuts at the bottom attaching

the turbine housing to the turbine

inlet adapter. see Figure 2. save the

turbine inlet gasket for reuse.

5.

unplug the electrical connector

at the driver-side of the compressor

housing.

the turbocharger pedestal mount

must be removed with the

turbocharger. remove the four bolts

attaching the pedestal mount to

the engine block. the front two are

easily accessible. the rear two will

require the use of a swivel socket or

a universal joint-socket combination.

After these bolts have been removed,

lift the assembly off of the engine

towards the front. remove the two

o-rings located on the engine or

under the pedestal mount.

6.

Clamp the turbocharger

assembly in a vise. Do not use the

compressor inlet or outlet to clamp

the turbocharger. the compressor

housing is aluminum and could

be damaged. observe and mark

the relationship of the exhaust

backpressure control valve to the

turbine housing and the turbine

housing to the center section of the

turbo assembly.

7.

Remove the exhaust backpressure

control valve from the turbine

housing, and install it onto the new

turbine housing with the original

hardware. Duplicate the orientation

of the original assembly. use anti-

seize on the bolts.

8.

remove the four bolts securing

the turbine housing to the

turbocharger center section. if the

turbocharger is more than a few

months old, it may be necessary

to spray some liquid wrench (or

similar rust penetrating lubricant)

into the joint between the turbine

housing and the center section.

work the housing loose from the

center section by tapping with a

hammer and brass drift or a soft

face hammer. work from side to

side and use plenty of lubricant until

the housing is loose from the center

section. Pull the housing straight

off of the center section to avoid

damaging the turbine blades.

9.

Place Banks Quick-turbo

®

turbine

housing onto the center section,

again paying careful attention to the

turbine blades. apply some anti-

seize to the four bolts and reinstall

them. Check the orientation of the

assembly, then tighten the bolts.

10.

make sure the gasket is on the

turbine inlet adapter on the engine.

Place the new o-rings provided into

the recesses on the engine block and

make sure that the sealing area of

the pedestal bottom is clean.

11.

reinstall the turbocharger and

pedestal assembly. make sure the

o-rings are in place before installing

any bolts. Put a small amount of

anti-seize on the turbine inlet bolts

and nuts and start them. install

and tighten the pedestal mounting

bolts then tighten the turbine inlet

bolts and nuts. Plug the electrical

connector back together.

12.

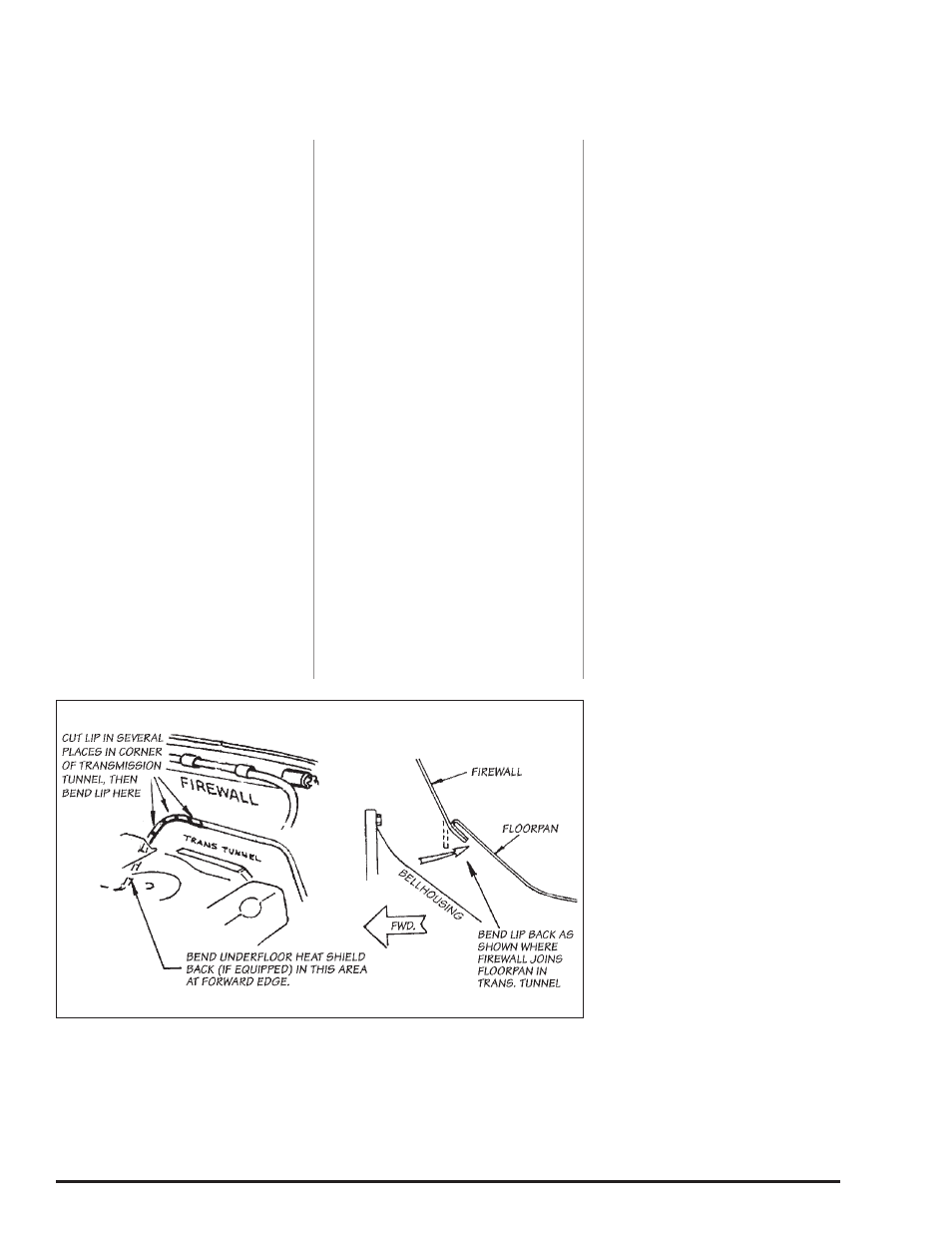

Bend the firewall lip seam as far

back as possible, on the right side

corner of the transmission tunnel, to

allow for installation of Banks two-

piece turbine outlet pipe. A 3-4 foot

piece of pipe or heavy metal bar may

be used as a lever and extended

hammer to fold and flatten the

seam against the floorpan. NOTE: If

access to a Sawzall or an air chisel is

available, a series of cuts in the seam

will ease the bending operation. It

may also be necessary to somewhat

compress and reshape the floorpan

heatshield behind the firewall lip

seam using a pipe or heavy prybar.

see Figure 3.

-EnD, SEcTIon 2-

Figure 3

96493 v.4.0

7