Banks Power Ford Trucks: (Diesel ’94 - 97 7.3L Power Stroke) Power Systems- PowerPack, Stinger-Plus & Stinger '94-98 4" Exhaust User Manual

Page 16

GAUGE PANEL

1.

if the gauges are being installed

into an existing gauge panel, this

step may be skipped. if gauges and

a gauge panel are being installed,

choose a location where the gauges

can be easily viewed by the driver.

this will typically be to the right of

the accelerator pedal, under the

lower edge of the dash panel. mount

the gauge panel with the machine

screws, washers, and nuts provided.

NOTE: Molded instrument panels for

top of dash mounting are available

from Gale Banks Engineering.

DYNAFACT PYROMETER

2.

install the Dynafact

®

pyrometer

probe (supplied in the pyrometer kit)

in the

1

⁄

4

-inch nPt bung located at

the top of the turbine outlet pipe.

Use anti-seize compound on the

threads. Connect the lead-wire to the

sensor with the supplied screws. the

wires are different lengths to prevent

cross connecting. make sure that the

screws are tight. slip the heat shrink

tubing provided over the wire ends.

3.

supply moderate heat to the heat

shrink tubing to seal the connections.

a heat-gun or lighter works well.

4.

when passing through the firewall

either make a hole in a factory

grommet or drill a hole and use a

new grommet. if a hole needs to

be drilled, drill a

5

⁄

16

-inch hole and

debur it on both sides, so that the

wiring or tubing does not get cut

as it passes through the hole. for

added protection, wrap the wiring

with several layers of electrical tape

in the area where it passes through

the hole. When drilling, check the

backside to make sure that there

are no components blocking the

backside of the hole that would be

damaged by drilling.

5.

route the pyrometer lead-wire

up and across the top of the firewall

then down and through the hole

in the firewall. Inside the vehicle,

route the wire to the gauge location.

if routing the lead-wire under the

carpet, avoid placing it where the

driver’s feet will rest on the wire. tie

the wire to existing wire looms and

hoses with the cable ties provided.

6.

Position the gauge through the

console or gauge panel. slip the

plastic U-clamp, provided with the

pyrometer, over the studs on the rear

of the gauge and tighten the nuts,

provided.

imPortant: remove the bare

shorting wire from between the

gauge terminals before connecting

the lead-wire to the pyrometer.

attach the spade connectors to

the back of the gauge. Connect the

yellow wire to the (+) terminal and

the red wire to the (-) terminal. if the

lead-wires are accidentally reversed,

the gauge will read backwards.

7.

Pull any excess wire through

the firewall, coil it and secure it up

under the dash, out of the way. Do

not shorten the lead-wire. Note: If

it is necessary to replace one of the

terminal ends, use a crimp tool only.

Do not solder to the wires.

Section 5

DYNAFACT INSTRUMENTATION INSTTALLATION

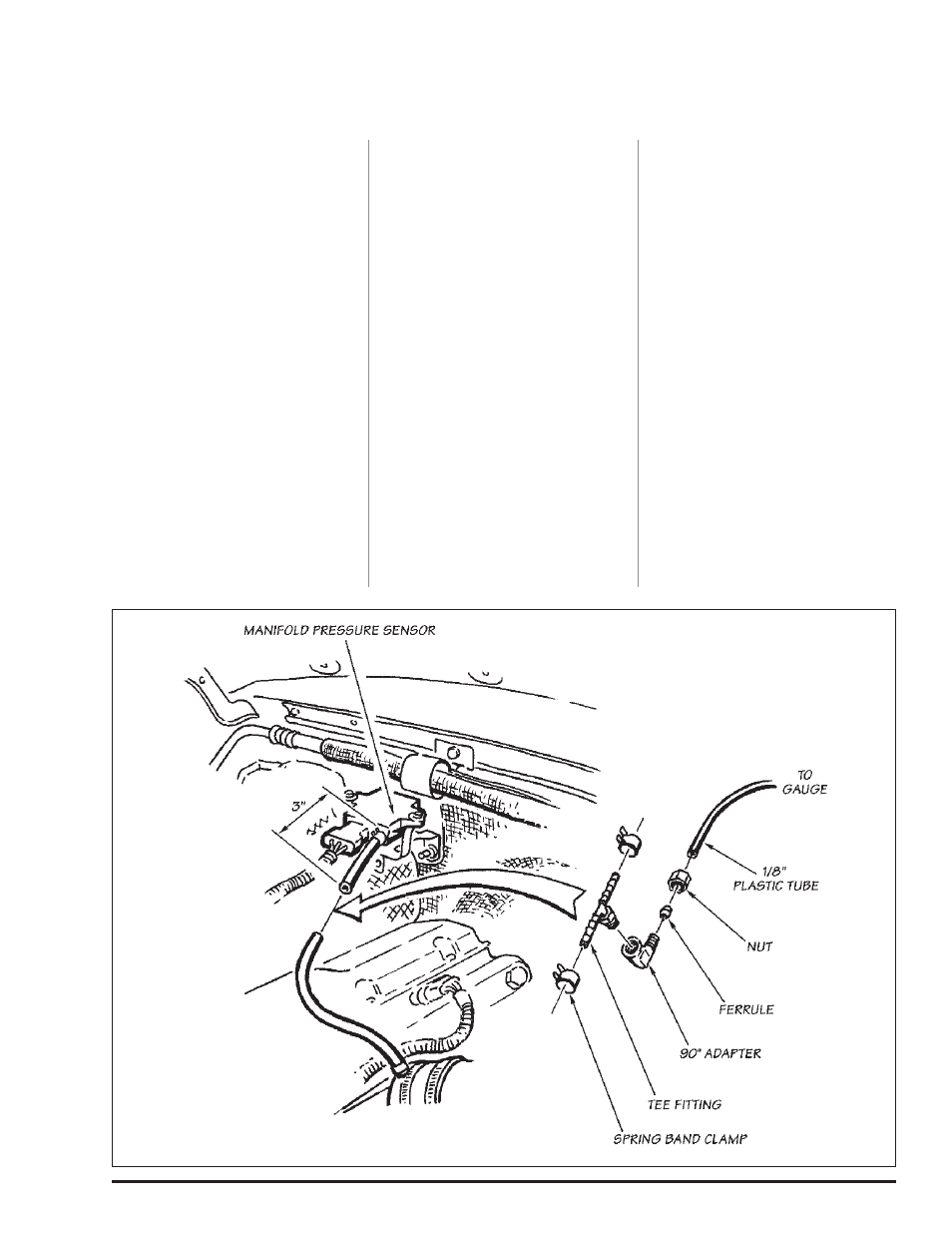

Figure 15

16

96493 v.4.0