Banks Power Chevy_GMC Trucks: Duramax LLY-LBZ (Diesel ’06 - 07 6.6L) Power Systems- PowerPack & Stinger Systems w EconoMind (LLY & LBZ) '06-07 (iQ) Compatible with Optional Banks iQ User Manual

Page 8

8

96816 v.3.0

ExHauST SYSTEM INSTaLLaTION

Use the Bill of Materials Chart and

Figure 1.0 or 1.1 to reference

component nomenclature and

location. Use caution when working

in the engine compartment. Make

sure the engine has been OFF for

several hours and cool.

1.

Disconnect the ground of the

battery (if there is more than one

battery, disconnect both).

2.

Raise the vehicle and support it

with properly weight rated safety

stands, ramps or a commercial hoist.

Follow the manufacturer’s safety

precautions. Take care to balance

the vehicle to prevent it from slipping

or falling. When using ramps, be

sure the front wheels are centered

squarely on the topsides; place the

transmission in park; set the parking

brake and place blocks behind the

rear wheels.

CauTION: DO NOT WORk uNDER

aNY VEHICLE SuPPORTED ONLY

BY a JaCk. SEVERE INJuRY MaY

RESuLT.

CauTION: The following step

involves cutting a stainless steel

tube. Safety glasses should

be worn during any cutting

operation and care should be

taken to avoid injury due to sharp

edges and burrs.

3.

Removal of the factory exhaust

can be simplified by cutting the

factory exhaust pipe behind the

muffler. This will allow the tailpipe to

be removed as a separate piece.

4.

Remove the clamp located on

catalytic converter outlet

5.

Remove the factory tailpipe

from the vehicle by disengaging the

exhaust system hanger pins from

the rubber insulators using a large

screw-driver or pry bar.

NOte: Lubricating the rubber hangers

with WD-40 or similar lubricant will

ease removal of the hanger pins.

6.

Remove the factory muffler

from the vehicle by disengaging

the hanger pins from the rubber

insulators using a large screwdriver

or pry bar.

7.

Install a 3.5” saddle clamp onto

the catalytic converter outlet.

8.

Insert the intermediate pipe inlet

onto the flanged intermediate pipe

outlet. Install the intermediate pipe

hanger pin(s) into the vehicle rubber

insulators.

NOte: Once the pipe has been

completely engaged in the slip

joint, it should be marked with a

marker, scribe or tape for reference

when tightening clamps later in the

installation. each slip joint in the

system should be marked in this

fashion. When the exhaust system is

being adjusted to align the hangers,

the slip joints can be adjusted so that

the reference mark is no more than

1

⁄

4

” away from its original position.

Step 16 thru 23 applies only to

single tailpipe systems.

Skip to Step 24 if installing Banks

Split-Dual Monster exhaust System.

Single Tailpipe System (Step 9

thru 16)

9.

Slide one (1) of the supplied

4-inch exhaust clamps over the

Banks intermediate pipe.

NOte: On extended cab long-bed

and crew-cab long-bed vehicle, the

clamp that is used between the

intermediate pipe and muffler is a

combination hanger/clamp. When

this hanger clamp is installed the

hanger pin should be inserted into

the factory rubber hanger and the

clamp should be rotated until the

hanger pin is parallel with the frame-

mounted pin before being torqued.

10.

Install the muffler onto the end

of the intermediate pipe outlet. Be

sure that the inlet side of the muffler

(see markings on muffler body)

is facing toward the front of the

vehicle. Orient the muffler such that

the “Banks Monster” logo is facing

towards the frame and is level with

the ground. Verify that the muffler

and intermediate pipe are completely

engaged.

11.

Slide one (1) of the supplied

4” exhaust clamps onto the Banks

Monster muffler outlet.

12.

Install the tailpipe into the outlet

of the muffler. Be sure that the two

pipes are completely engaged. Insert

the front and rear tailpipe hanger

pins into the factory rubber hangers.

Rotate the tailpipe until the hanger

pins are parallel with the frame

mounted pin.

NOte: Minimum distance between

exhaust tip and body a one (1) inch.

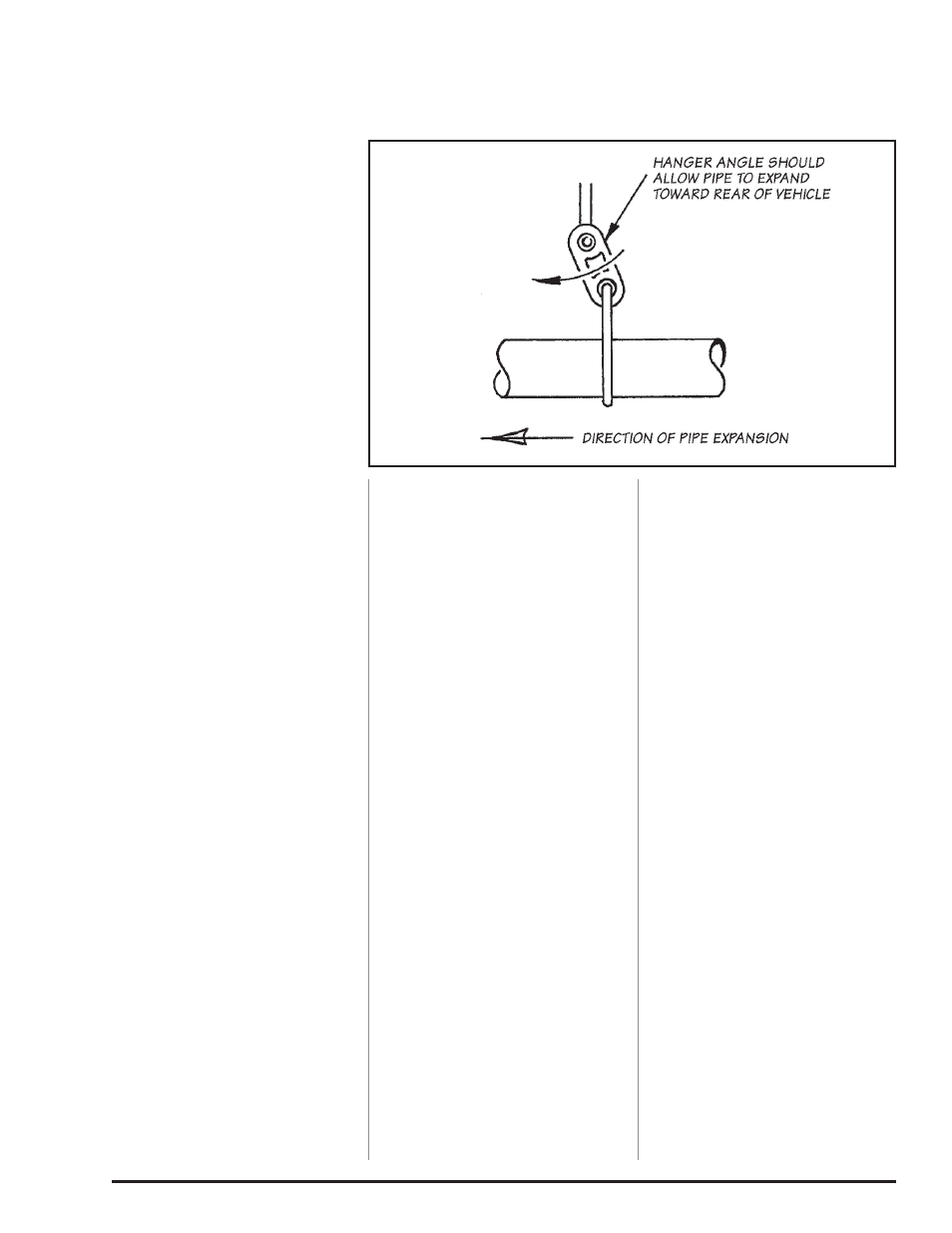

13.

Adjust each of the pipes to

ensure that all of the hanger pins

are parallel with the frame-mounted

pins and that the rubber hangers are

all positioned slightly forward (See

Figure 1.2). The amount of forward

angle on the rubber hangers should

increase the farther downstream the

hanger is positioned. This allows the

hangers to be properly positioned

once the exhaust system reaches

operating temperature.

14.

Tighten the head pipe V-band

clamp to 12 ft-lbs (if previously

loosened).

15.

Install the exhaust clamp

at each of the three (3) joints.

Figure 1.3 illustrates the proper

location of an exhaust clamp on a

tubing joint. Torque the nuts on each

of the exhaust clamps to 35 ft-lb.

Figure 1.2