Rotor drive, Rotor – Milton CAT PM 102 User Manual

Page 3

3

Rotor

Designed for high production and long service life. Quick release conical tool holders for

quick and easy tool replacement.

98 carbide-tipped tools. Tools are

mounted in durable three-piece, quick

release patented tool holders and

arranged in a triple wrap flighting

pattern for maximum breakout force.

Quick release conical tool holders. A

tapered fit maintains tightness in holder

base. Fast and effortless tool removal is

provided by the quick release conical

tool holder tool removing system.

Large replaceable carbide faced

loading paddles. Loading paddles

effectively move milled material onto

collecting conveyor resulting in higher

production and less wear on inside of

rotor chamber and cutting tools.

Optimum tool spacing. Triple-tree tool

placement on rotor ends provides

optimum tool spacing to clean up loose

material and reduces wear on drum

when maneuvering in the cut.

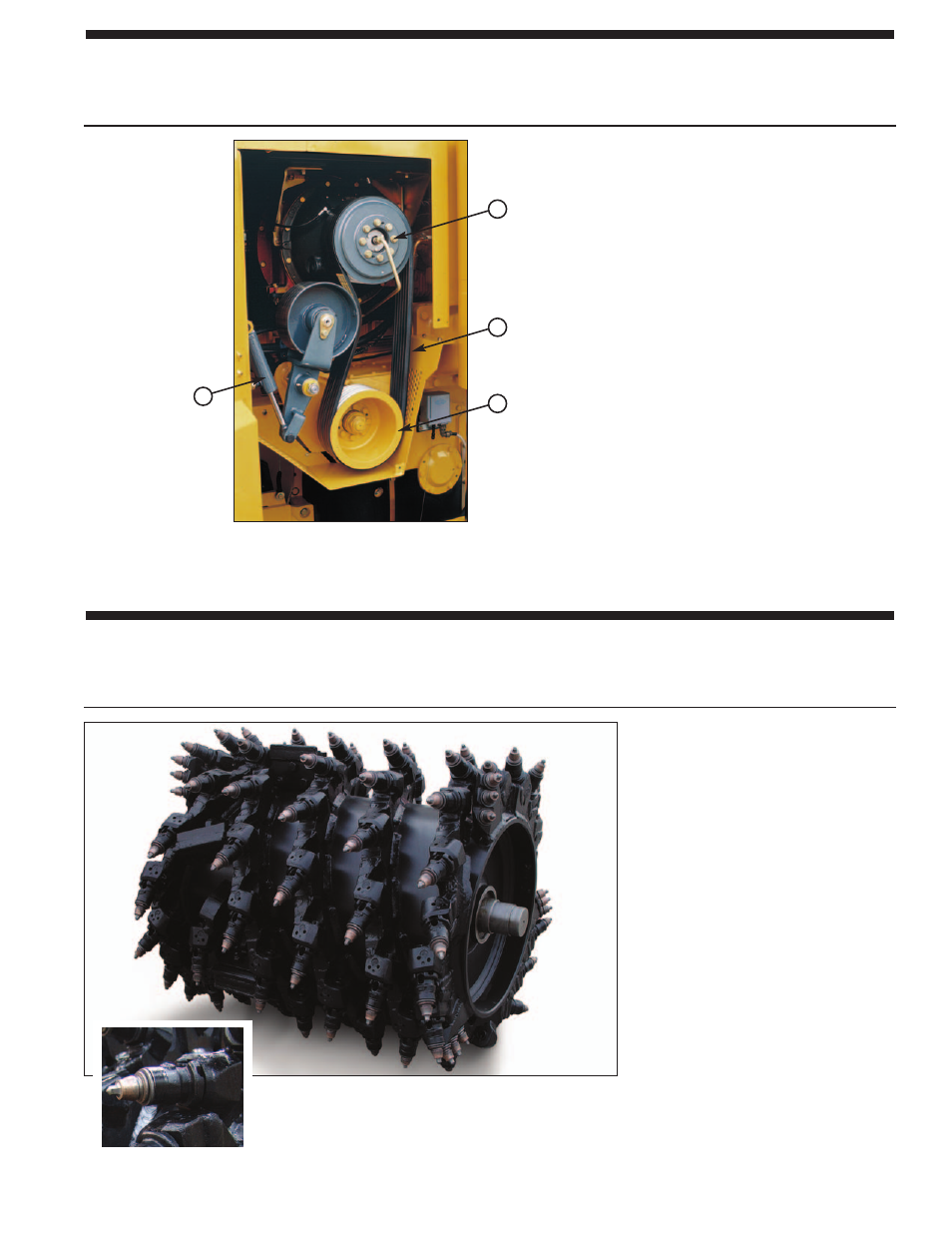

Rotor Drive

Delivers maximum available horsepower to each cutting tool.

Mechanical dry clutch. The rotor drive

consists of trapezoid pulleys, molded

high-strength belt and a hydraulic-

coupling dry clutch. The field-proven

drive system delivers reliability and

long service life.

Drive train protection. A drive train

protection device protects rotor drive

system, rotor and tools by instantly

disengaging rotor drive whenever an

abrupt drop in rotor rpm occurs.

Two cutting speeds. Upper and lower

sheaves are easily interchangeable for

maximum torque with the toughest

materials and different material sizing

requirements.

Molded six-rib high tensile belt. High

tensile belt provides efficient

transmission and long service life.

Automatic belt tension adjustment. The

hydraulically powered automatic drive

belt tensioner prevents rotor drive belt

slippage and reduces maintenance.

1 Upper Sheave

2 Molded Drive Belt

3 Lower Sheave

4 Tension Cylinder

1

2

3

4

Quick release three-piece tool holder.