Caterpillar® 3126b ataac engine, Propel system, Caterpillar – Milton CAT PM 102 User Manual

Page 2: 3126b ataac engine

2

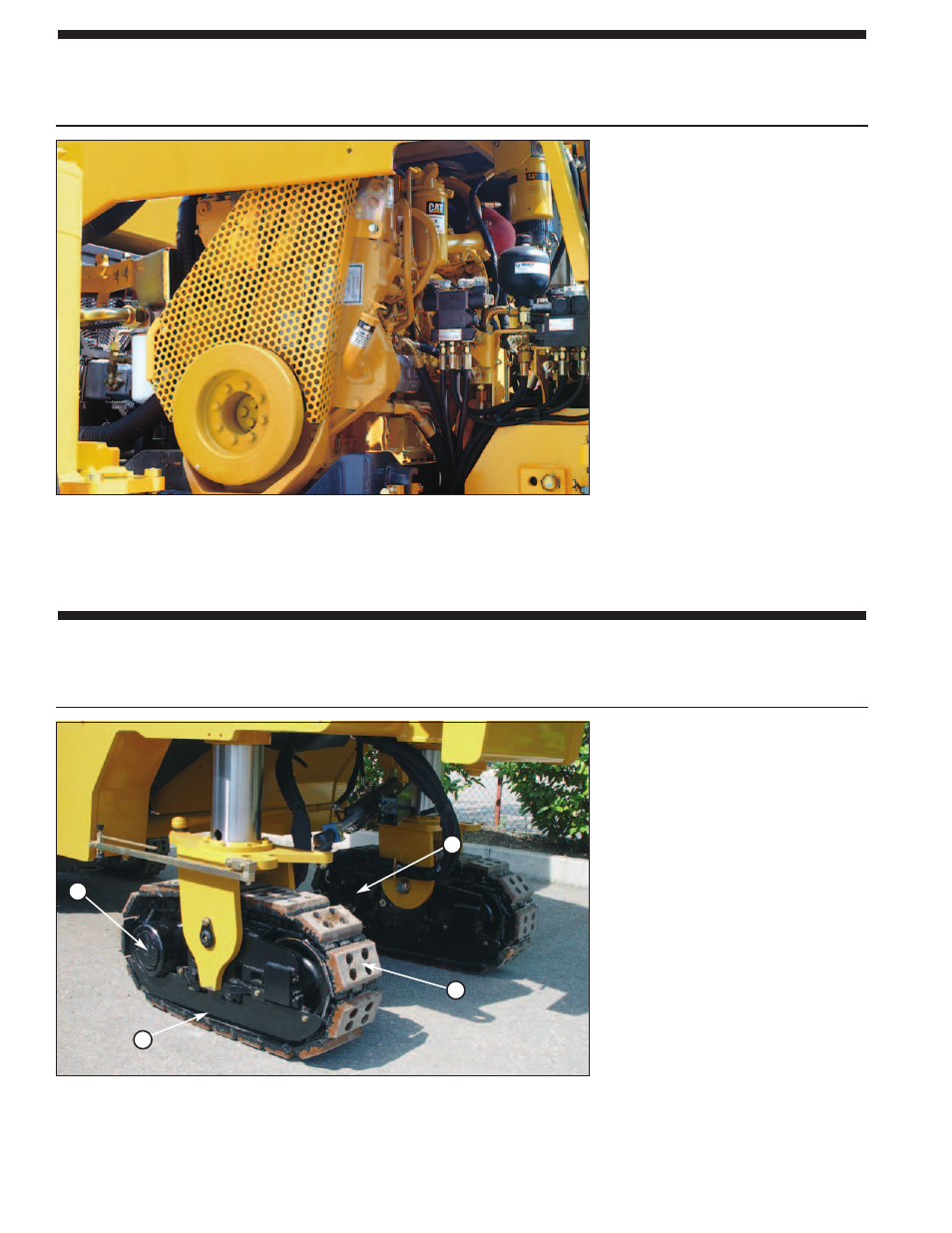

Propel System

Hydrostatic drive with hydraulic flow provided by a variable displacement axial piston

pump. Dual displacement drive motors on each track provides balanced tractive effort.

Load control system (anti-stall).

The electronically controlled system

matches propel speed to load on engine

for maximum production.

Two speed ranges. The machine

operates at either maximum torque

throughout the entire milling speed

range or at a faster travel speed for

moving around the job site.

Positive traction control (flow divider).

Equal hydraulic oil flow to each drive

motor increases tractive effort in hard

cutting applications. The positive

traction control is actuated from the

operator’s console.

Polyurethane track pads. Track pads in

polyurethane provide long service life

and positive traction on all pavement

surfaces.

1 Two Speed Drive Motor

2 Polyurethane Track Pads

3 Heavy-duty Rollers

4 Planetary w/Secondary Brake

2

1

Caterpillar

®

3126B ATAAC Engine

Dependable, field-proven, efficient Cat power with optimized power curve for milling

applications. Engine is U.S. EPA Tier 2 and European EU Stage II compliant.

Cat diesel engine. The engine offers

outstanding value by combining

industry leading electronic capabilities,

performance and reliability with

optimum fuel economy.

Optimized power curve. Engine power

curve is optimized for milling

applications providing optimum power

while keeping the engine operating at

peak efficiency.

Turbocharged and air-to-air aftercooling

(ATAAC). High horsepower with

increased response time is assured

while keeping exhaust temperatures low

and in concert with the tight tolerance

combustion chamber components,

maximizing fuel efficiency and

minimizing emissions.

Hydraulic electronic unit injection.

This feature provides reduced engine

noise, improved fuel economy, faster

hot and/or cold starts and better high

altitude performance.

3

4