Reliability and serviceability – Milton CAT PM 200 User Manual

Page 9

9

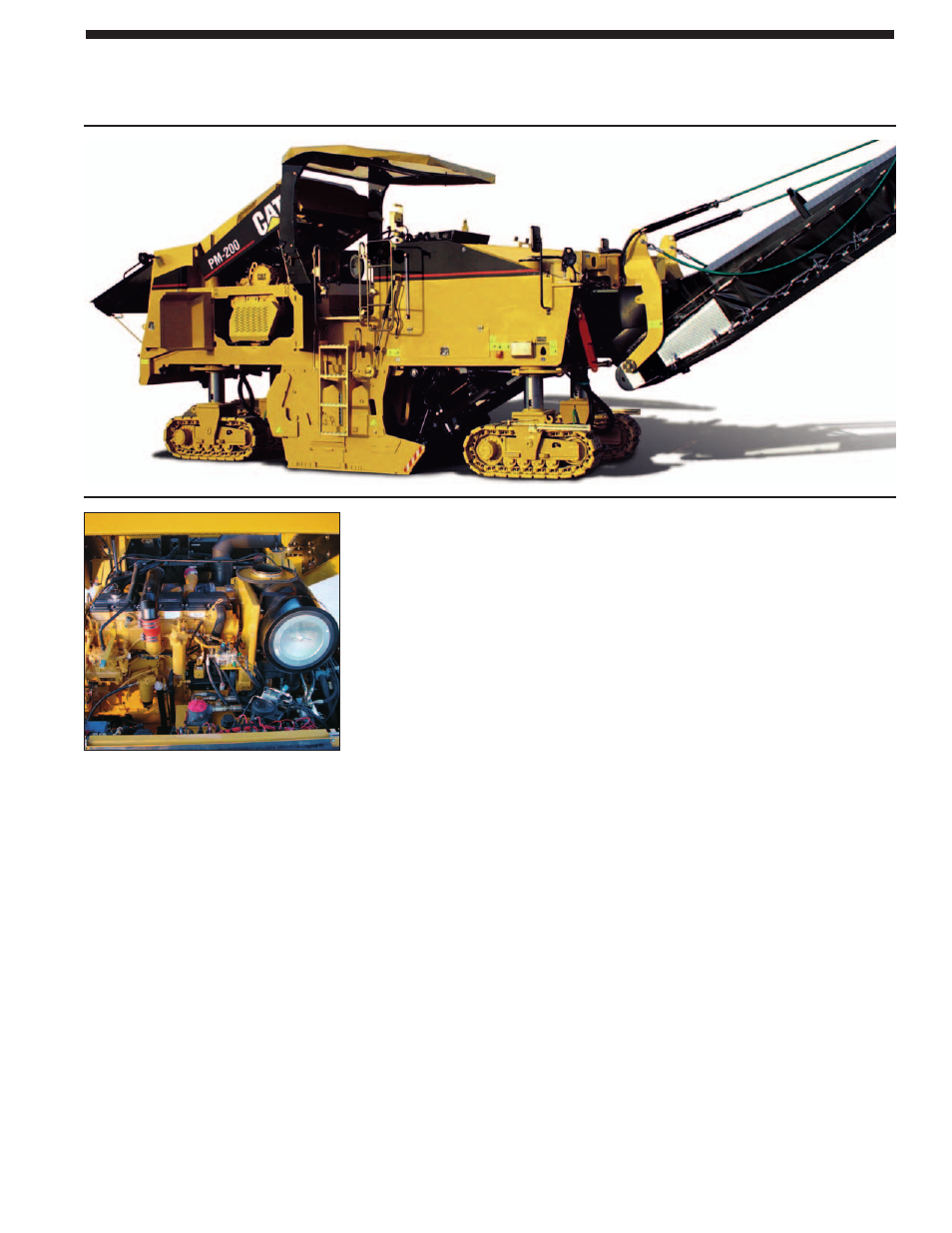

Reliability and Serviceability

Reliability and serviceability are integrated into every Caterpillar machine. These

important features keep your machine investment profitable.

Hydraulic rotor service door. Service

door opens wide for convenient access

to rotor for inspection and tool

maintenance.

Electronic Control Module (ECM).

Machine systems are monitored

providing self-diagnostics for operator

or service personnel.

Three warning levels. Operator is

alerted to conditions on the machine that

requires attention. Encourages repair

before major failure.

Level One – operator can continue to

operate however the system requires

attention soon.

Level Two – operator should change

machine operation or perform the

required maintenance to the system as

soon as possible.

Level Three – represents the most

severe condition and the machine should

be shut down immediately in a safe

manner.

Visual indicators. Visual indicators

allow easy check of water spray tank

level and hydraulic oil tank level.

Quick-connect hydraulic test ports.

Quick-connect feature simplifies system

diagnostics.

Ecology drains. Environmental method

to drain fluids. They are included on the

radiator, engine oil pan, hydraulic and

fuel tank.

S•O•S

SM

ports. Scheduled Oil Sample

ports allow for simple fluid collection of

hydraulic oil.

Secure hose routing. Polyethylene

routing blocks provide a secure routing

to reduce rubbing and increase service

life of hoses.

Maintenance-free Caterpillar batteries.

Batteries are mounted at the rear of the

machine. Batteries are specifically

designed for maximum cranking power

and protection against vibration.

Cooling package. The cooling package

is a single plane design, stacked in

series for easy access for cleaning and

service. A modular stacked cooling

system provides more efficient cooling

of individual systems and makes routine

cleaning easier.

Accessory drive system. In an engine

not running condition or non-operational

auxiliary hydraulic system, full

operational control of main machine

functions are readily available for

assisted machine movement for

maintenance and servicing.

The power-assist engine hood opens

wide to provide excellent access to the

engine, air filter, hydraulic components

and daily service points.