Automatic grade and slope control, Maneuverability – Milton CAT PM 201 User Manual

Page 9

9

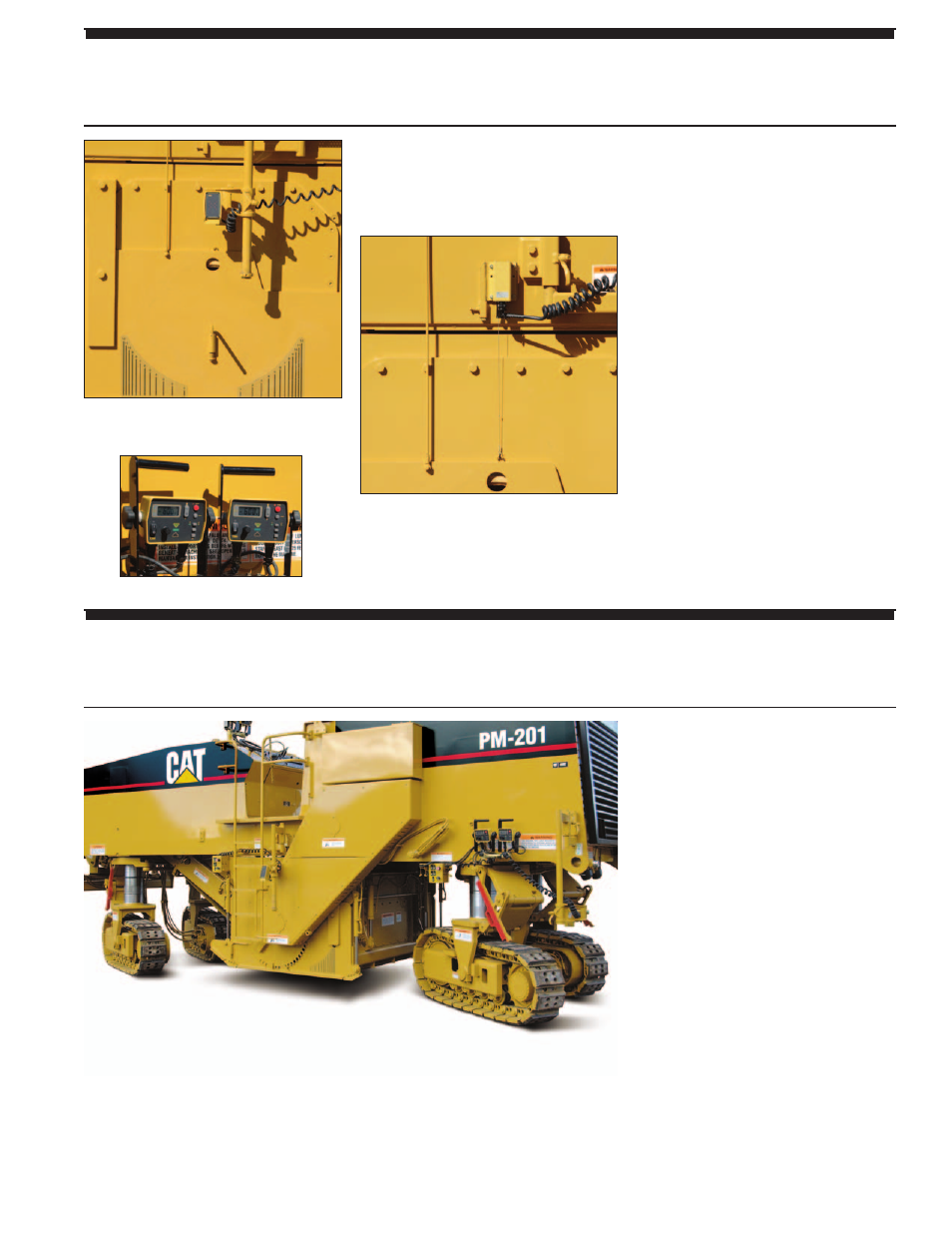

Contact or non-contact grade sensors

can be positioned on each side are easy

to position and provides a consistent

accuracy to ± 3 mm (1/8"). Cross slope

sensor adds to system versatility.

Contacting wire rope grade sensor

measures side plate movement that

enables the entire length of the side

plate to become an averaging device for

extremely accurate grade matching.

Remote mounted control boxes allow

manual or automatic operation from

either the operator’s station or at ground

level. Constant read-out for rotor depth

and cross slope are easily visible in

direct sunlight or low light conditions.

Sonic Averaging System features three

non-contacting grade sensors or a

combination of one contacting and two

non-contacting sensors that mount on

the side of the machine. Enables the

entire length of the machine to become

an averaging device.

Automatic Grade and Slope Control

The optional contacting or non-contacting grade controls provide precise control of the

machine to a preset cutting depth. System can be configured to control grade or cross slope.

Steering control provides four steering

modes for maneuvering in tight

quarters: front steer only, crab steer,

coordinated steer and rear steer only.

Standard reinforced polyurethane track

pads provides good traction, added

stability and improved durability

against track pad separation.

Visibility to the cutter box side plates is

exceptional. Excellent visibility

increases productivity and allows the

operator to precisely place the rotor

against gutter pans or when working

near obstructions.

Dual propel levers provide infinitely

variable machine speeds for moving

around the job site quickly.

Maneuverability

Four steering modes provide excellent handling for precise control and production.

Non-contacting grade sensor.

Contacting grade sensor.

Remote mounted control boxes.