Operator’s station, Electronic control module – Milton CAT PM 201 User Manual

Page 8

8

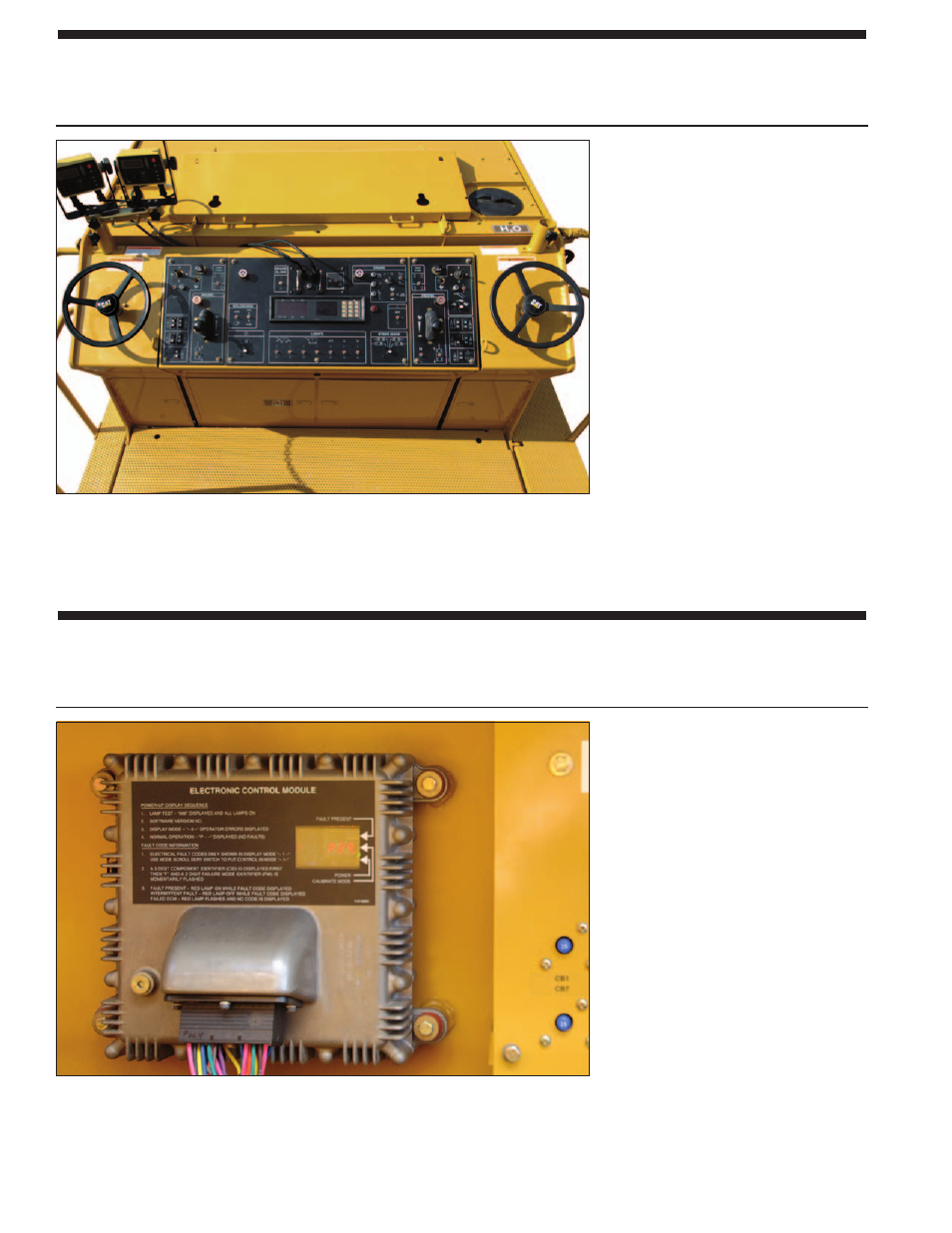

Electronic Control Module

Reliable Caterpillar technology that makes machine operation simple and self-diagnostics

simplifies troubleshooting.

Reliable Caterpillar technology

achieves maximum productivity and

simplifies troubleshooting.

Electronic Control Module (ECM)

receives input signals from sensors in

the engine, propel, steering and rotor

drive systems which monitor current

operating conditions.

Self-diagnostics provides information

for troubleshooting and alerts the

operator of potential system problems.

Automatic load control adjusts propel

speed so that engine speed is

maintained at no less than 1900 rpm.

Machine always works at peak

efficiency for maximum production.

Steering control provides four steering

modes for maneuvering in tight

quarters: front steer only, crab steer,

coordinated steer and rear steer only.

Operator’s Station

Designed for efficiency, productivity and simple operation from either side of the console.

Easy to reach controls minimize operator fatigue.

Dual operating controls including

steering wheels, propel levers, upper

conveyor, machine elevation and rear

track steering functions.

Computerized Monitoring System (CMS)

constantly monitors system pressures

and engine condition with six modes of

operation. Alerts the operator if a

problem does occur with three levels

of warning.

Clear control and instrumentation

layout designed for ease of use. All

gauges and displays are easily visible in

direct sunlight or low light conditions.

Isolated platform with four heavy-duty

rubber mounts to reduce machine

vibration transmitted to the operator.

Low sound levels help the operator and

ground crew communicate effectively.

Warning horns and shut down buttons

located on the operator’s station and at

five ground level control stations.