Grade and slope control, Conveyor system, Hydraulic system – Milton CAT PM 201 User Manual

Page 13: Service refill capacities, Water spray system, Electrical, Frame

13

PM-201 specifications

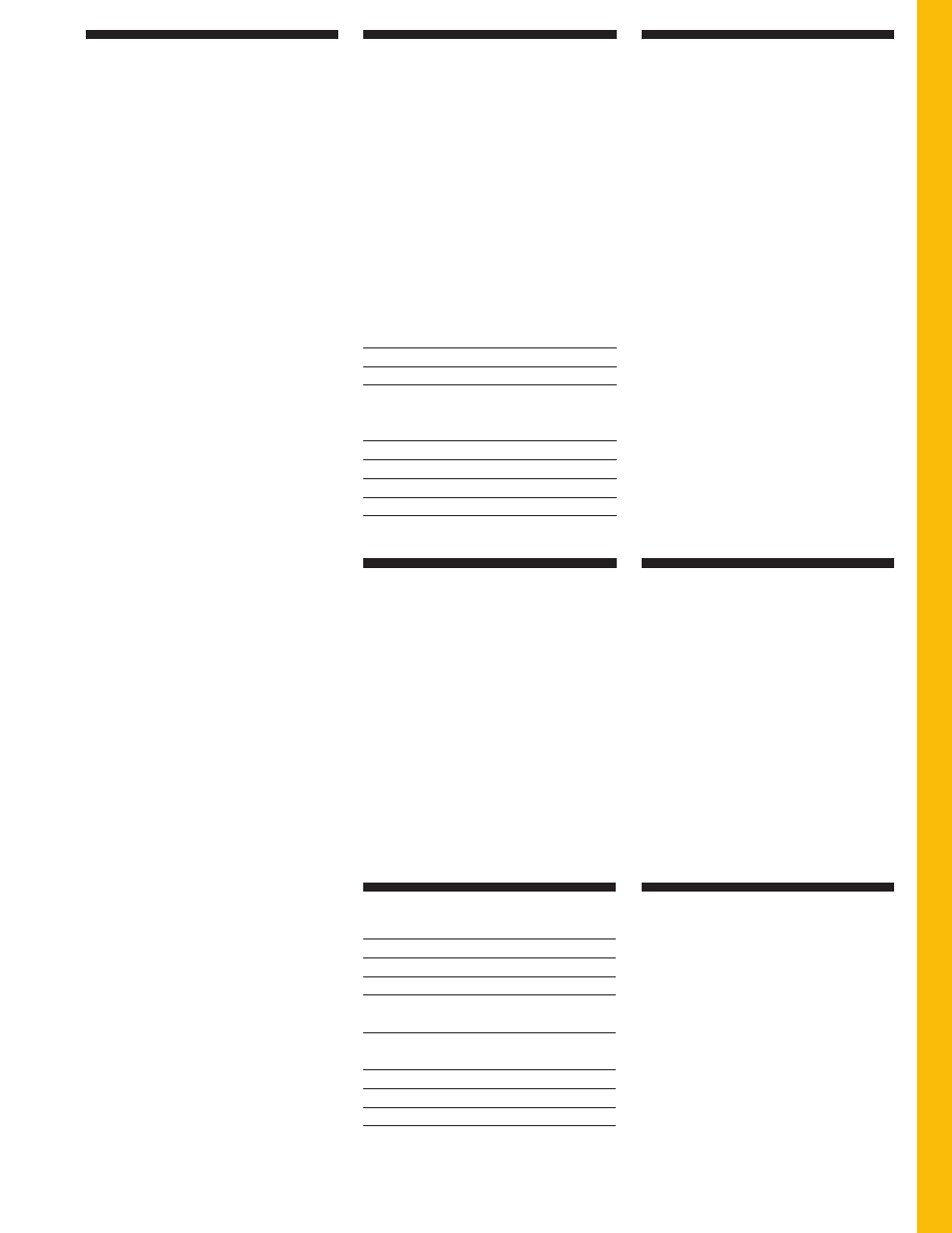

Service Refill Capacities

Liters

Gallons

Fuel tank (useable)

946

250

Cooling system

80

21.1

Engine oil w/filter

64

17

Propel planetary

gear reducer (each)

4.2

1.1

Rotor planetary

gear reducer

14

3.7

Rotor mandrel coolant

307

81

Hydraulic tank

180

47.5

Rotor clutch sump

45

11.9

Water spray system

3787

1000

Grade and Slope Control

Machine elevation – rotor depth and

cross slope controlled manually by

operator is standard. Automatic rotor

depth and slope control is optional and

features electronic over hydraulic

control. System can be configured with

contacting or non-contacting grade

sensors. Slope sensor adds versatility.

Features

■

Machine elevation controls located on

the operator’s console and at ground

level allows rotor depth and cross slope

to be controlled manually. Visual depth

gauge displays depth of cut.

■

The optional AUTOMATIC grade

and slope control automatically

controls rotor depth and cross slope to

a preset cutting depth. Setting cutting

depth is easily accomplished first in

manual mode by using the adjustment

knob on the controller.

■

Remote mounted control boxes allow

manual or automatic operation from

either the operator’s station or at

ground level. A cross communication

function allows the operator to view

and change settings of control boxes

located on the opposite side of the

machine. This allows operators a

means to control both sides of a job

from a single location. Constant read-

out for rotor depth and cross slope

are easily visible in direct sunlight.

■

Sonic grade control sensors can be

positioned on each side are easy to

position and provides a consistent

accuracy to ± 3 mm (1/8").

■

Wire rope contacting grade sensor

measures side plate movement that

enables the entire length of the side

plate to become a mini averaging ski

for optimum grade matching.

■

Sonic Averaging System features

three non-contacting grade sensors or

a combination of one contacting and

two non-contacting sensors that

mount on the side of the machine.

Enables the entire length of the

machine to become an averaging

device. Eliminates the need for a

contact type ski for greater machine

maneuverability.

■

Remote mounted control boxes and

sonic grade sensors can be easily

removed and securely stowed to

prevent damage or theft.

Hydraulic System

■

Pumps for propel, rotor drive,

collecting and upper conveyors,

auxiliary hydraulics and cooling fan

are installed on the engine mounting

pad.

■

Hydraulic oil cooler located at the

rear of the machine and arranged in a

modular stacked design for efficient

cooling and easy access for cleaning.

■

Three-micron filtration on pressure

side of auxiliary flow, seven-micron

filtration on return side.

■

Quick-connect hydraulic test ports

simplify system diagnostics.

Water Spray System

■

Hydraulically-driven centrifugal

pump supplies water to spray nozzles

for dust control and collecting belt

lubrication.

■

Centrifugal pump is rated at 206

L/min (55 gpm) at 276 kPa (40 psi).

■

Water spray nozzles focuses the

water spray in a flat fan pattern to the

rotor for better cooling of cutting

tools.

■

Nozzles are easily removed for

inspection and replacement without

the need for tools.

■

Automatic water spray system

operates only when the rotor is

engaged and machine is moving

forward to conserve water.

■

System includes gauges to monitor

water pressure, replaceable filters, a

low water level indicator and water

control valves to conserve water

usage.

■

Water tank can be filled from the top

of the machine or at ground level.

Conveyor System

■

Collecting conveyor is driven by two

high torque hydraulic motors to

ensure even belt tracking and clears

out the rotor housing effectively.

■

Variable belt speed for front loading

conveyor controls loading of milled

materials to closely match material

type and amount.

■

Boost function increases material

handling to load long tractor trailers.

■

Raise, lower and swing controlled

from the operator’s station and at two

ground level control stations.

Collecting Conveyor

Length

3.74 m

12' 3"

Width

1020 mm

40"

Speed

189 mpm

620 fpm

Upper Conveyor

Length

8.31 m

27' 3"

Width

915 mm

36"

Max. speed

231 mpm

760 fpm

Speed w/boost

293 mpm

960 fpm

Swing (from center)

45 degrees

Electrical

The 24-volt electrical system consists

of two maintenance-free Cat batteries.

Electrical wiring is color-coded,

numbered, wrapped in vinyl-coated

nylon braid and labeled with

component identifiers. The starting

system provides 1365 cold cranking

amps (cca). The system includes a

100-amp alternator.

Frame

Fabricated from heavy gauge steel

plates and structural steel tubing. Track

assembly features track frame stops to

limit track angles to provide machine’s

ability to propel up inclines and out of

deep cuts. Top of deck and steps

features non-skid treads for sure

footing.