Flat-base type insulated type – C&H Technology PS11011 User Manual

Page 3

MITSUBISHI SEMICONDUCTOR

PS11011

FLAT-BASE TYPE

INSULATED TYPE

Jan. 2000

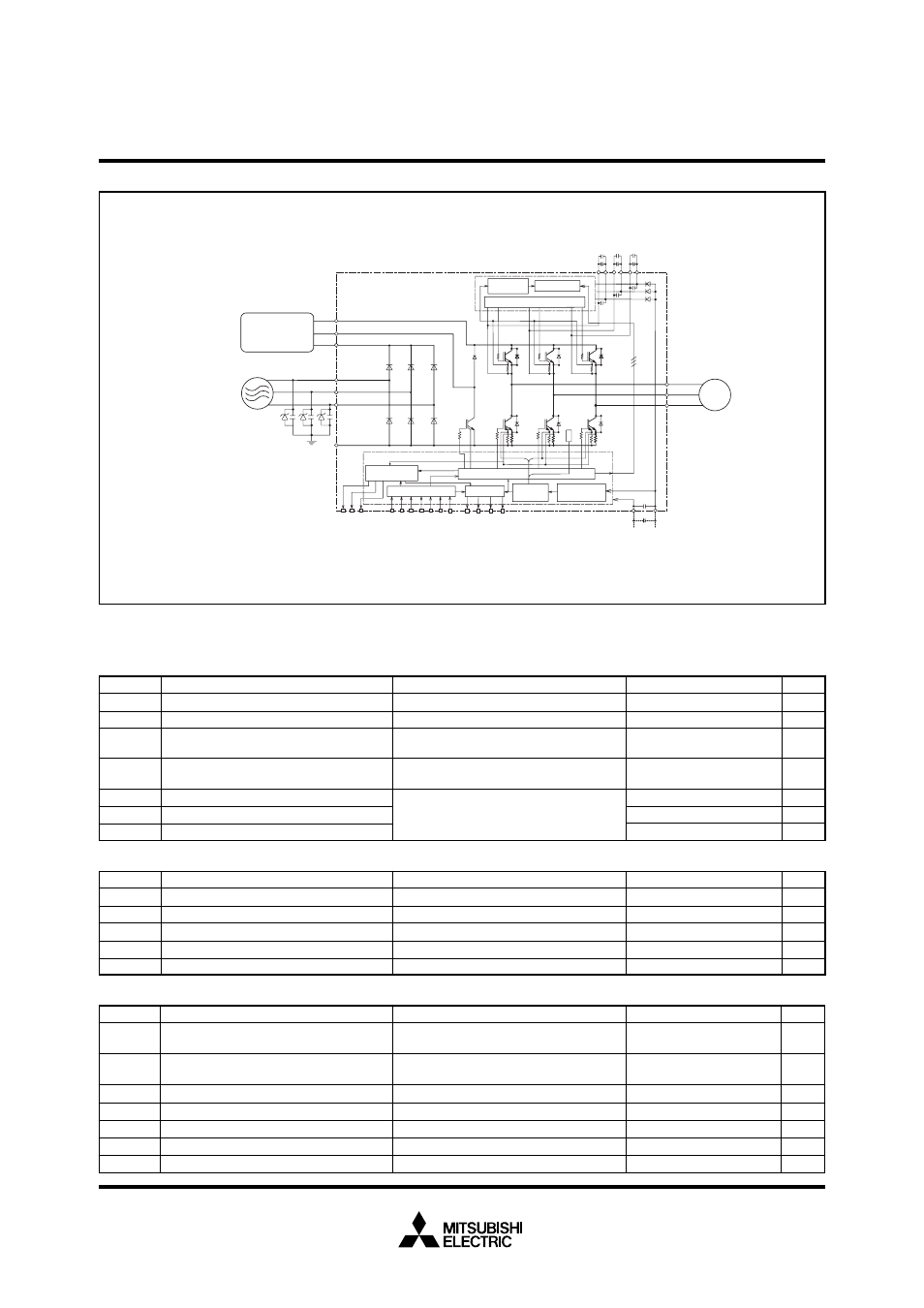

(15V line)

VDH

GND

CUCV CW

U

P

V

P

W

P

U

N

V

N

W

N

B

r

CL FO1 FO2 FO3

B

P2

P1

R

S

T

C

Z

N

M

W

V

U

AC200V line input

C3 ; 3.3

µ

F or more, tight tolerance, temp-compensated electrolytic type (Note : the value may change

depending on the type PWM control scheme used in the applied system)

C4 ; 2

µ

F R-category ceramic condenser for noise filtering.

C2 ;

3.3

µ

F or more

FO Logic

Protection

Circuit

Level shifter

Drive Circuit

Drive Curcuit

Trig signal conditioning

Current sensing

circuit

Protection

circuit

Control supply

fault sense

Z : Surge absorber.

C : AC filter (Ceramic condenser 2.2~6.5nF)

[Note : Additionally an appropriate Line-to line

surge absorber circuit maybe necessary

depending on the application environment].

AC 200V line

output

Brake resistor

connection,

Inrush prevention

circuit, etc.

Note 1) To prevent chances of signal oscillation, an RC coupling at each output is recommended. (see also Fig.10)

Note 2) By virtue of integrating an application specific type HVIC inside the module, direct coupling to CPU, without any opto or transformer isolation ispossible. (see also Fig.10)

Note 3) All these outputs are open collector type. Each signal line should be pulled up to plus side of the 5V power supply with approximately 5.1k

Ω

resistance. (see also Fig.10)

Note 4) The wiring between power DC link capacitor and P/N terminals should be as short as possible to protect the ASIPM against catastrophic high surge voltage. For extra

precaution, a small film type snubber capacitor (0.1~0.22

µ

F, high voltage type) is recommended to be mounted close to these P and N DC powerinput pins.

Analogue signal output corresponding to

each phase current (5V line) Note 1)

Each phase input (PWM)

(5V line) Note 2)

Fault output

(5V line) Note 3)

CBU–

CBU+

CBV–

CBV+

CBW–

CBW+

C4,C3

Application Specific Intelligent

Power Module

T.S.

C2

Each output IGBT collector current

Brake IGBT collector current

Brake diode anode current

INTERNAL FUNCTIONS BLOCK DIAGRAM

(Fig. 2)

V

V

450

500

Applied between P2-N

Applied between P2-N, Surge-value

Applied between P-U, V, W, Br or U, V, W,

Br-N

Applied between P-U, V, W, Br or U, V, W,

Br-N

T

C

= 25

°

C

Note: “( )” means I

C

peak value

Supply voltage

Supply voltage (surge)

V

CC

V

CC(surge)

Condition

Symbol

Item

Ratings

Unit

MAXIMUM RATINGS

(Tj = 25

°

C)

INVERTER PART (Including Brake Part)

V

P

or V

N

V

P(S)

or V

N(S)

±

I

C

(

±

I

CP

)

I

C

(I

CP

)

I

F

(I

FP

)

Each output IGBT collector-emitter static voltage

Each output IGBT collector-emitter

switching surge voltage

600

600

±

2 (

±

4)

2 (4)

2 (4)

V

V

A

A

A

V

20

Fault output supply voltage

Fault output current

Current-limit warning (CL) output voltage

CL output current

Analogue current signal output current

Applied between V

DH

-GND, C

BU+

-C

BU–

,

C

BV+

-C

BV–

, C

BW+

-C

BW–

Applied between U

P

· V

P

· W

P

· U

N

· V

N

·

W

N

· B

r

-GND

Applied between F

O1

· F

O2

· F

O3

-GND

Sink current of F

O1

· F

O2

· F

O3

Applied between CL-GND

Sink current of CL

Sink current of CU · CV · CW

V

DH

, V

DB

Supply voltage

Symbol

Item

Ratings

Unit

CONTROL PART

Condition

V

FO

I

FO

V

CL

I

CL

I

CO

V

CIN

Input signal voltage

–0.5 ~ 7.5

–0.5 ~ 7

15

–0.5 ~ 7

15

±

1

V

V

mA

V

mA

mA

3

φ

rectifying circuit

1 cycle at 60Hz, peak value non-repetitive

Value for one cycle of surge current

Condition

Symbol

Item

Ratings

Unit

V

RRM

Ea

I

O

I

FSM

I

2

t

Repetitive peak reverse voltage

Recommended AC input voltage

DC output current

Surge (non-repetitive) forward current

I

2

t for fusing

800

220

25

138

80

V

V

A

A

A

2

s

CONVERTER PART