VEGA WEIGHTRAC 31 Profibus PA User Manual

Page 50

50

7 Setup with PACTware

WEIGHTRAC 31 • Profibus PA

43837-EN-131119

Adjustment

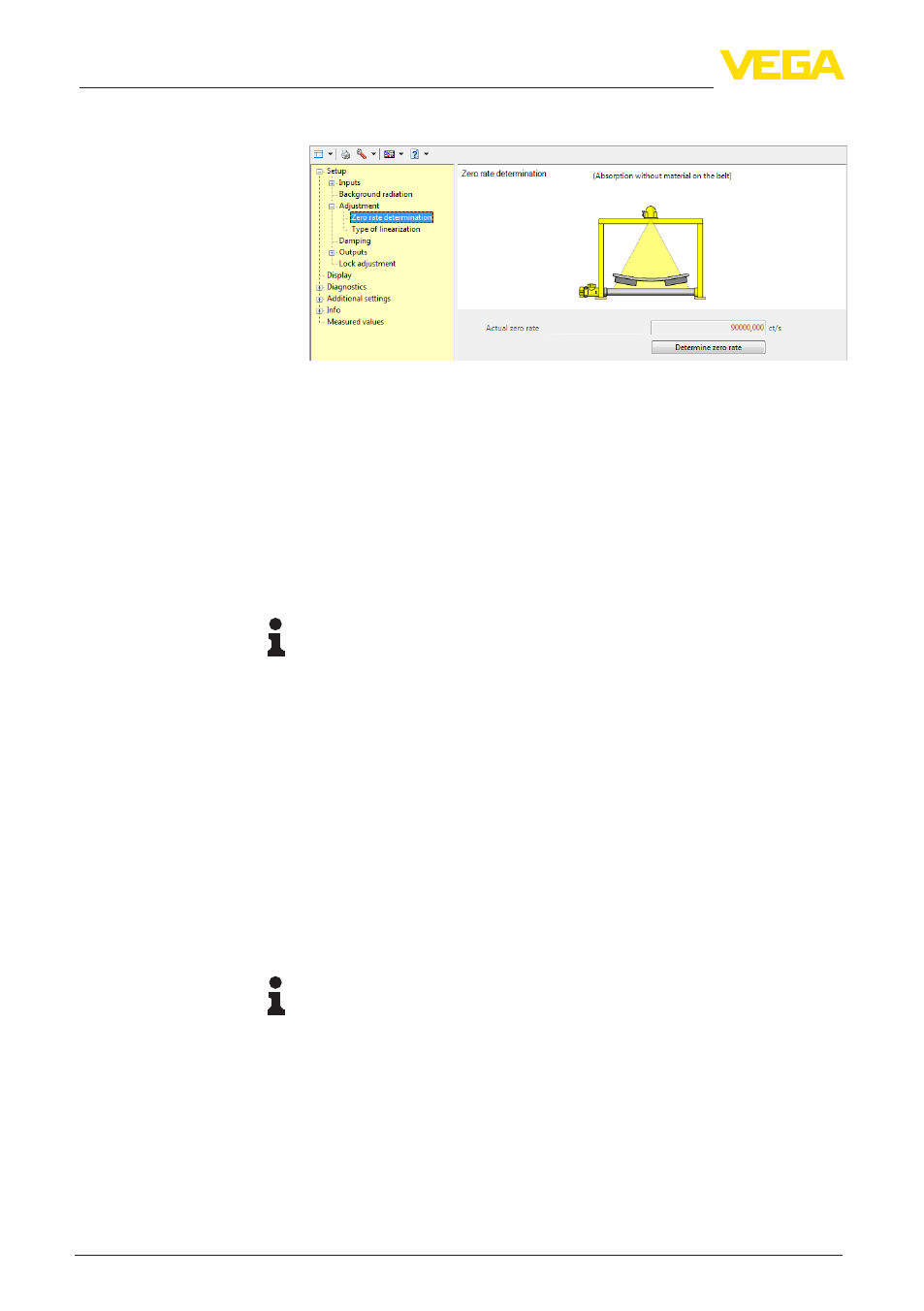

Fig. 33: Determine zero rate (tare measurement)

To increase accuracy, you have to carry out the zero rate determina-

tion with an empty conveyor belt. During the zero rate determination

make sure that no material is transported and that no residues fall

onto the conveyor belt. In such case, you have to repeat the proce-

dure.

The conveyor belt should make several circulations to compensate for

irregularities of the conveyor belt or the conveyor system. The more

often the conveyor belt circulates during the zero rate determination,

the more precise the zero rate determination will be.

Tip:

To check the zero rate determination (taring), you can carry out a test

measurement after the adjustment with empty belt over a period of

5 to 10 minutes. If no or only a negligible feed rate sums up during

the measurement, the zero rate determination has been carried out

correctly.

1. Start empty conveyor belt and let it run idle

Tip: Mark the conveyor belt with coloured adhesive tape

2. Set the source container to "ON"

3. Click the button "Determine zero rate"

4. Let the conveyor belt run for two to three belt lengths

5. Terminate the zero rate determination

6. Stop conveyor belt

The determined value of the zero rate is transferred to the sensor

Note:

In case of heavy belt wear, this zero rate determination should be car-

ried out regularly to keep the accuracy constant.

If you exchange the belt, you have to carry out the zero rate determi-

nation again.

In this menu item you can carry out the adjustment of the sensor.

During linearization, a corresponding total weight of conveyed mate-

rial is assigned to a particular pulse rate.

Adjustment - Zero rate

determination (DTM)

Adjustment - Lineariza-

tion (DTM)