Measurement error during filling – VEGA VEGAPULS 61 (≥ 2.0.0 - ≥ 4.0.0) 4 … 20 mA_HART four-wire Approval according to LPR radio standard User Manual

Page 59

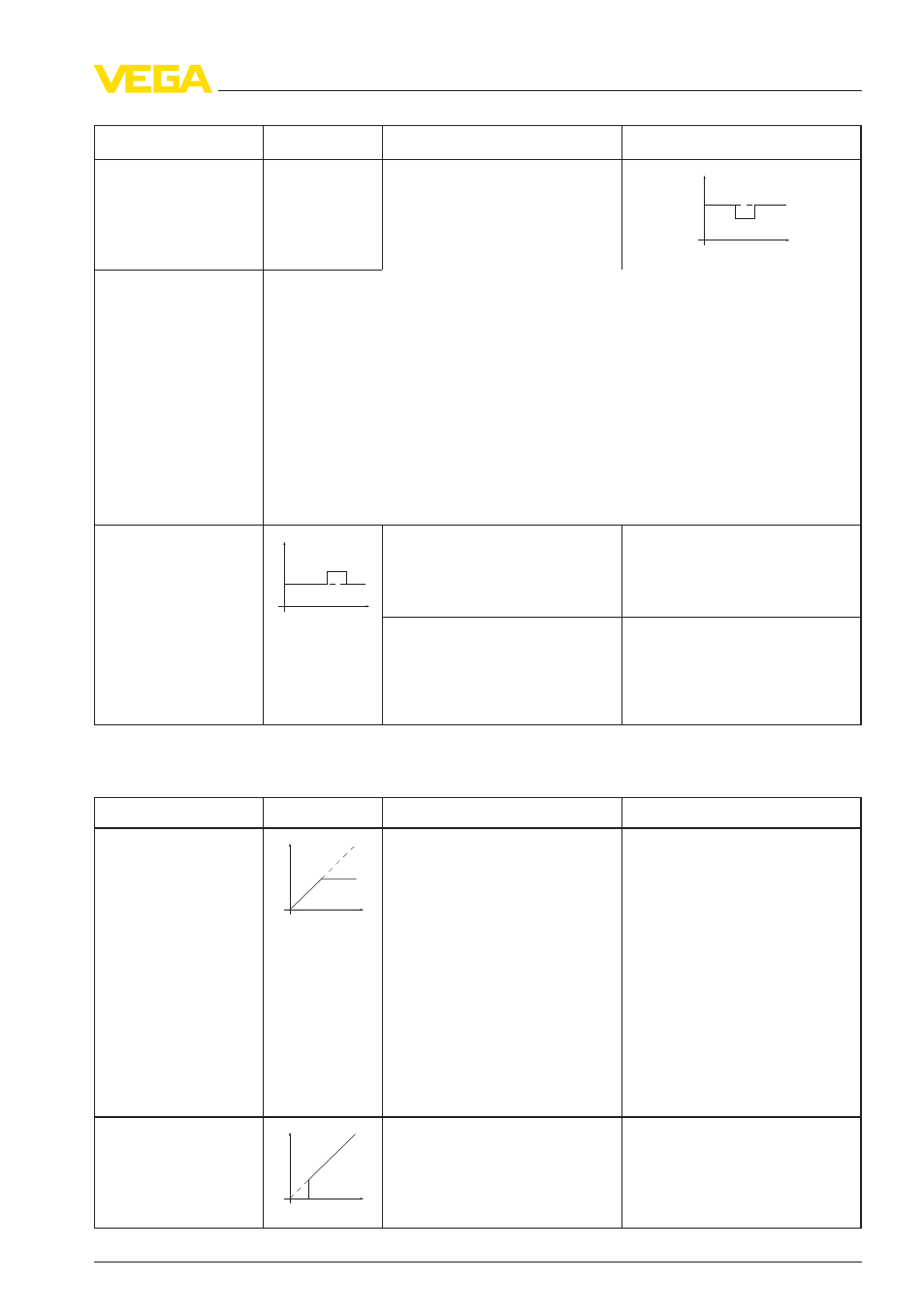

Fault description

Error pattern

Cause

Rectification

2. Measured value jumps towards

0 %

Level

time

0

l Multiple echo (ves-

sel top, product sur-

face) with amplitude

higher than the level

echo

l Check para-

meter

"

Applica-

tion", in par-

ticular Ves-

sel top,

Product ty-

pe, Dished

bottom, High

dielectric va-

lue and

adapt if ne-

cessary

3. Measured value

jumps towards 100 %

Level

time

0

l Due to the process, the amp-

litude of the product echo sinks

l A false signal suppression was

not carried out

l Carry out false signal suppres-

sion

l Amplitude or position of a false

echo has changed (e.g. con-

densation, buildup); false sig-

nal suppression no longer

matches

l Determine the reason for the

changed false echoes, carry

out false signal suppression, e.

g. with condensation

Measurement error during filling

Fault description

Error pattern

Cause

Rectification

4. Measured value re-

mains unchanged du-

ring filling

Level

time

0

l False echoes in the close

range too big or product echo

too small

l Strong foam or spout genera-

tion

l Max. adjustment not correct

l Remove false echoes in the

close range

l Check measurement situation:

Antenna must protrude out of

the socket, installations

l Remove pollution on the an-

tenna

l Minimize interfering installa-

tions in the close range by

changing the polarization di-

rection

l Create a new false signal sup-

pression

l Adapt max. adjustment

5. Measured value re-

mains in the bottom

section during filling

Level

time

0

l The tank floor echo is larger

than the product echo, e.g.

with products with ε

r

<

2.5 oil-

based, solvents

l Application parameter "Me-

dium", check Vessel height and

Floor form, adapt if necessary

VEGAPULS

61 • Approval according to LPR radio standard

59

9 Diagnosis, Asset Management and service

41714

-EN

-120301