Measurement error during emptying, Constant level, Filling – VEGA VEGAFLEX 82 Foundation Fieldbus User Manual

Page 60

60

9 Diagnostics and service

VEGAFLEX 82 • Foundation Fieldbus

44221-EN-130910

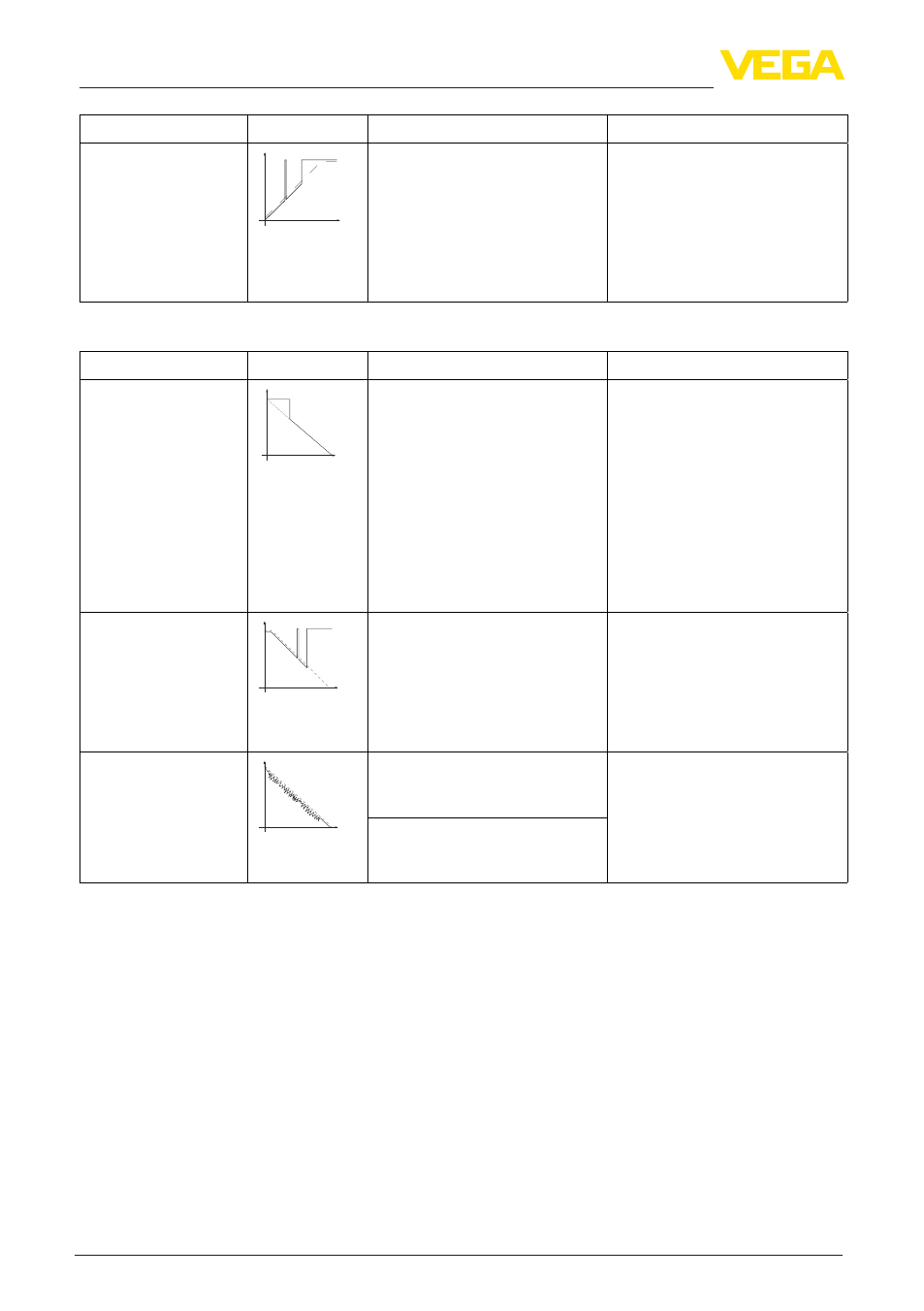

Fault description

Error pattern

Cause

Rectification

5. Measured value

jumps sporadically to

100 % during filling

Leve

l

time

0

– Varying condensation or con-

tamination on the antenna

– Carry out a false signal sup-

pression or increase false

signal suppression with con-

densation/contamination in the

close range by editing

– With bulk solids use radar sen-

sor with purging air connection

or flexible antenna cover

Measurement error during emptying

Fault description

Error pattern

Cause

Rectification

6. Measured value re-

mains unchanged in

the close range during

emptying

Level

time

0

– False echo larger than the level

echo

– Level echo too small

– Remove false echoes in the

close range. Check: Antenna

must protrude out of the socket

– Remove contamination on the

antenna

– In case of interferences due to

installations in the close range:

Change polarisation direction

– After removing the false ech-

oes, the false signal suppres-

sion must be deleted. Carry out

a new false signal suppression

7. Measured value

jumps sporadically to-

wards 100 % during

emptying

Level

time

0

– Varying condensation or con-

tamination on the antenna

– Carry out false signal suppres-

sion or increase false signal

suppression in the close range

by editing

– With bulk solids use radar sen-

sor with purging air connection

or flexible antenna cover

8. Measured val-

ue fluctuates around

10 … 20 %

Level

time

0

– Various echoes from an uneven

product surface, e.g. an extrac-

tion funnel

– Check parameter "Type of

medium" and adapt, if neces-

sary

– Optimize installation position

and sensor orientation

– Reflections from the product

surface via the vessel wall

(deflection)

The below tables show typical examples for application-relevant

measurement errors. There are two measurement errors:

•

Constant level

•

Filling

•

Emptying

The images in column "Error pattern" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

Treatment of measure-

ment errors