VEGA VEGAMET 624 User Manual

Page 38

38

8 Application examples

VEGAMET 624 • 4 … 20 mA/HART

28969-EN-130701

•

Pump control 1: The upper switching point determines the switch-

off point for the relay, whereas the lower switching point deter-

mines the switch-on point

•

Pump control 2: The upper switching point determines the switch-

on point for the relay, whereas the lower switching point deter-

mines the switch-off point

Two pumps should empty the vessel when a certain level is reached.

At 80 % filling, the pump with the shortest running time should switch

on. If the level nevertheless increases, a second pump should switch

on at 90 %. Both pumps should switch off again at 10 % filling.

Select in the DTM navigation section the menu items "Meas. loop -

Outputs - Relay".

•

Set mode "Pump control 2" for relay 1 and 2.

•

Enter the switching points for the affected relays as follows:

– Relay 1 upper switching point = 80.0 %

– Relay 1 lower switching point = 10.0 %

– Relay 2 upper switching point = 90.0 %

– Relay 2 lower switching point = 10.0 %

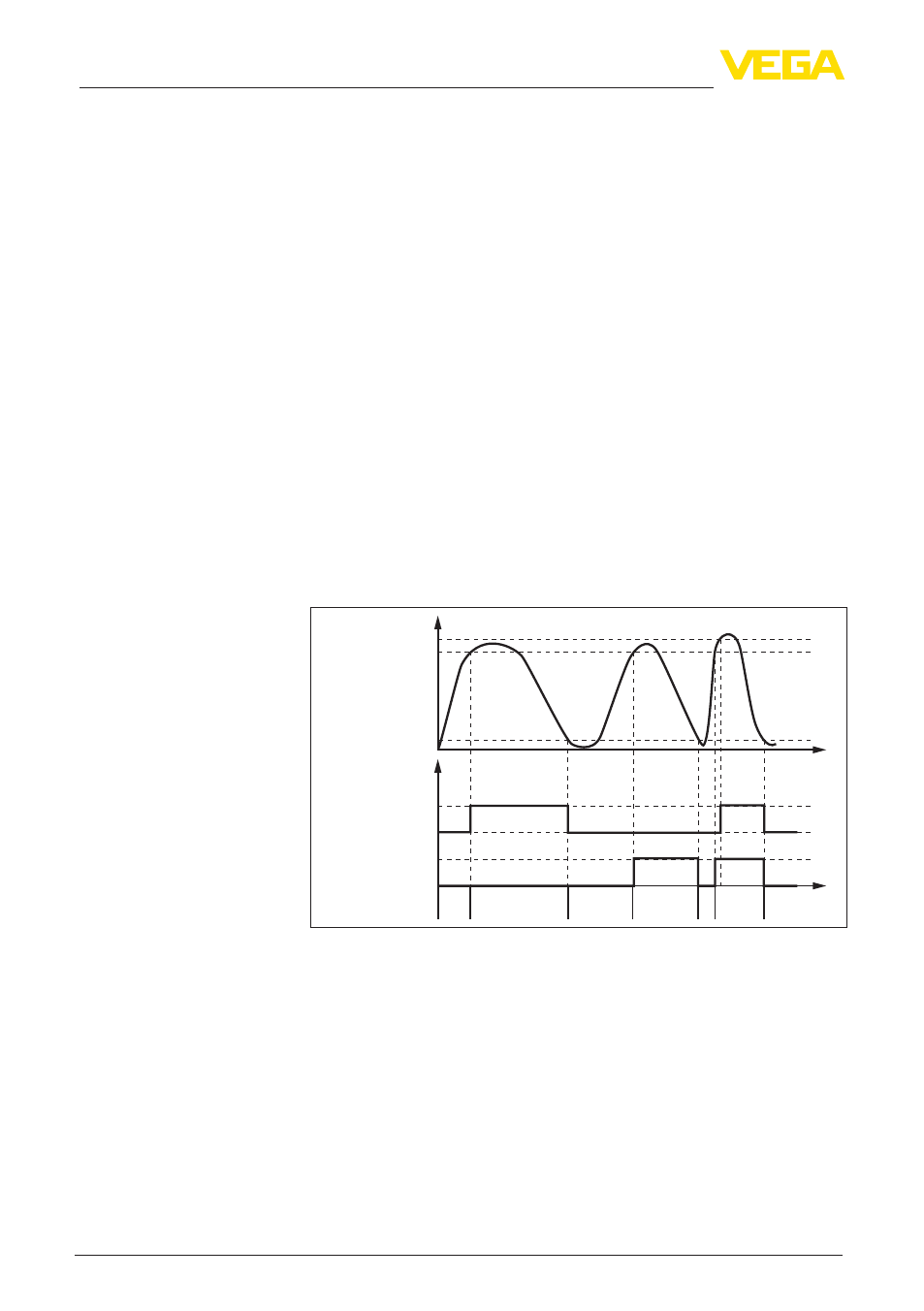

The function of pump control 2 is shown in detail in the following dia-

gram. The previously described example is used as a basis.

Rel. 1: 80% On

On

Off

Off

On

Rel. 2: 90% On

Rel. 1, 2: 10% Off

10

30

20

20

15

t [h]

5

Rel. 1

Rel. 2

Fig. 12: Example of pump control 2

Switch on reaction of the pump control 2

When the signal conditioning instrument is switched on, the relays are

at first in a switched-off status. Depending on the input signal and the

switched-on period of the individual relays, the following relay switch-

ing conditions can occur after the start procedure:

•

Input signal is higher than the upper switching point -> Relay with

the shortest switch on period is switched on

•

Input signal is between lower and upper switching point -> Relay

remains switched off

•

Input signal is smaller than the lower switching point -> Relay

remains switched off

Example

Setup