Foam generation, Wrong orientation to the product, Sensor too close to the vessel wall – VEGA VEGAPULS 54K enamel User Manual

Page 14

14

VEGAPULS 54K enamel

24 101-EN-041227

If there are good reflection conditions (liquid

medium, no vessel installations), we recom-

mend locating the sensor where there is no

vessel wall within the inner emission cone. For

products in less favourable reflection envi-

ronments, it is a good idea to also keep the

outer emission cone free of interfering instal-

lations. Note chapter "4.1 General installation

instructions“.

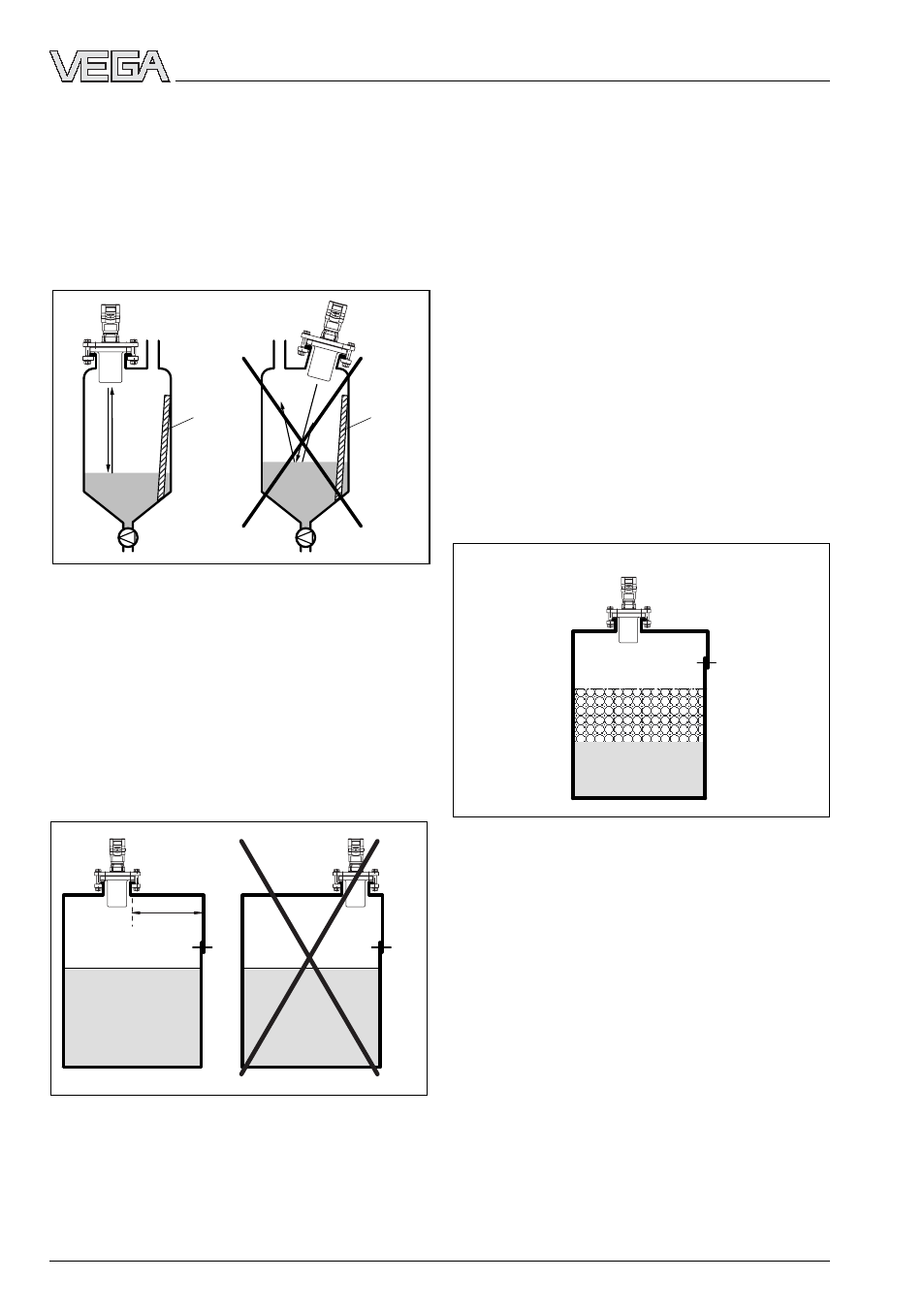

Foam generation

Thick, dense and creamy foam on the prod-

uct can cause incorrect measurements. Take

measures to avoid foam, measure in a by-

pass tube or use another measuring technol-

ogy, e.g. capacitive meas. probes or

hydrostatic pressure transmitters.

Foam generation

Mounting and installation

Wrong orientation to the product

Weak measuring signals are generated if the

sensor is not directly pointed at the product

surface. Orient the sensor axis perpendicu-

larly to the product surface to achieve opti-

mum measuring results.

Sensor too close to the vessel wall

If the radar sensor is mounted too close to

the vessel wall, strong false echoes can be

caused. Buildup, rivets, screws or weld joints

superimpose their echoes onto the product

i.e. useful echo. Please ensure a sufficient

distance from the sensor to the vessel wall.

Direct sensor vertically to the product surface

Correct

Incorrect

Ladder

Ladder

Sensor too close to the vessel wall