Connections to the bypass tube – VEGA VEGAPULS 43 4 … 20 mA; HART compact sensor User Manual

Page 16

16

VEGAPULS 43 – 4 … 20 mA

26626-EN-041227

Welding beads too large

Connections to the bypass tube

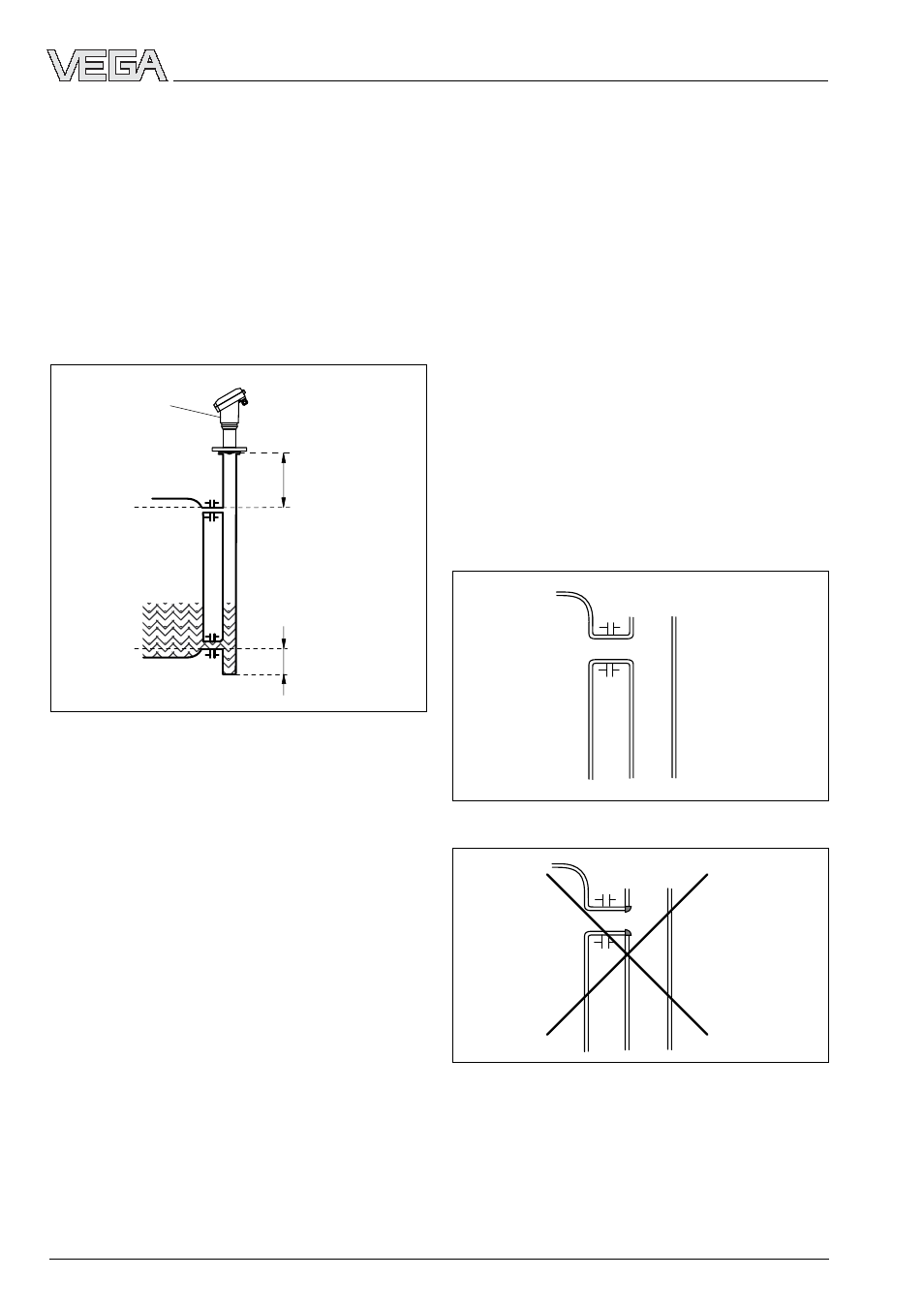

The connections to the bypass tubes must

be fashioned in such a way that only minimal

reflections are caused by the walls of the

connecting tubes. This is especially important

for the breather connection in the upper part

of the tube. Observe the following points:

• Use small openings for the connection.

• The diameter of the connecting tubes

should not exceed 1/3 of the bypass diam-

eter.

• The tube connections must not protrude

into the bypass tube.

• Large welding beads in the tubes should

be avoided.

• Additional connections to the bypass tube

must lie in the same plane as the upper

and lower vessel connection (above each

other or displaced by 180°).

Optimum connection to the bypass tube

100 %

0 %

> 300 mm

300 ... 800 mm

Tube flange system as bypass tube

Type label

For products with small dielectric constants

(< 4), the bypass tube should have a length

greater than would normally be required for

the lower tube connection. Products with

small dielectric constants are partly pen-

etrated by the radar signals, allowing the

tube bottom to produce a stronger echo than

the product (when the bypass tube is nearly

empty). By extending the tube downward,

some liquid remains at the bottom even when

the vessel is completely empty.

Mounting and installation

If enough liquid (300 … 800 mm) remains in

the blind lower end of the tube, the portion of

the signal that penetrates the liquid and re-

flects from the tube bottom is sufficiently

damped - the sensor can then easily distin-

guish it from the echo of the liquid surface. In

cases where there is not enough liquid at the

bottom of the tube, a deflector situated there

will carry out the same function. It deflects

signals that reach the tube bottom into the

standard connection opening.