VEGA VEGAFLEX 52P (Profibus PA) User Manual

Page 26

26

VEGAFLEX 51P and 52P

Electrical connection

In the so-called Fieldbus Intrinsically Safe

Concept (FISCO), the general conditions for

an Ex safe bus configuration have been laid

down. Therein the participants and the bus

cables with their electrical data have been

determined, so that the linking of these com-

ponents always meets the Ex requirements.

A more time-consuming Ex calculation is

therefore not necessary. You can build your

Ex bus according to the IEC standard 1158-

2.

The Ex segment coupler delivers a controlled

power supply to the PA bus. All other compo-

nents (field instruments and bus terminators)

are only consumers. A field instrument must

consume at least 10 mA. Ideally, an individual

sensor should not consume more than

10 mA, so that the number of instruments can

be as large as possible.

VEGA PA sensors, whether Ex or non Ex,

consume a constant current of 10 mA. Ac-

cording to the Profibus specification, this is

the minimum participant current. With VEGA

sensors it is therefore possible to connect 10

sensors (also in Ex environment) even with a

limited energy supply from the Ex segment

couplers.

Watch out for potential losses

Due to potential losses, earthing on both

sides without a potential equalisation system

is not allowed in Ex applications. If an instru-

ment is used in hazardous areas, the re-

quired regulations, conformity and type

approval certificates for systems in Ex areas

must be noted (e.g. DIN 0165). Please also

note the approval documents with the safety

data sheet attached to the Ex sensors.

Ex protection

If an instrument is used in hazardous areas,

the required regulations as well as the dust-

Ex certificates of VEGAFLEX for systems in

dust-Ex areas must be noted.

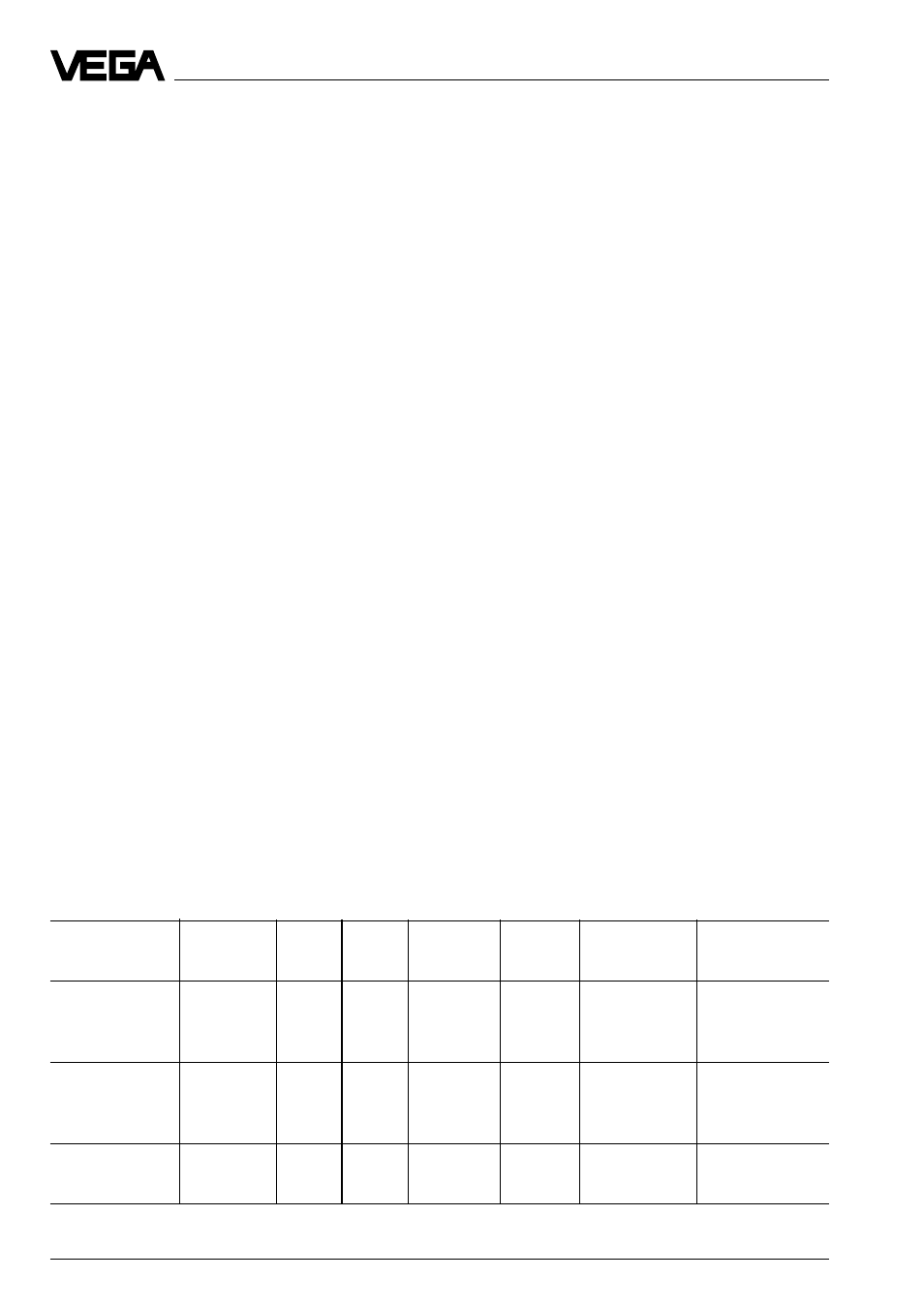

Electrical data of the cables

R

DC

No. of A in

Z

31.25kHz

C in

Damping

Screen

cores

mm

2

nF/km

SINEC 6XV1

44

W/km

2

0.75

100

W

< 90

< 3 dB/km

Cu braiding

830-5AH10

+/- 20

W

39 kHz

(Siemens)

SINEC L26XV1 44

W/km

2

0.75

100

W

< 90

< 3 dB/km

Cu braiding

830-35H10

+/- 20

W

39 kHz

(Siemens)

3079A

105

W/km 2

0.32

150

W

29.5

< 3 dB/km

Foil

(Belden)

39 kHz