2 setup steps – VEGA VEGAMET 381 User Manual

Page 25

25

6 Setup with the integrated display and adjustment unit

VEGAMET 381 • 4 … 20 mA signal conditioning instrument

27567-01-131025

F

E

DC

B A 9 8 7 6

5 4

32

1

0

-

+

1

2

1

3

7

6

5

2

4

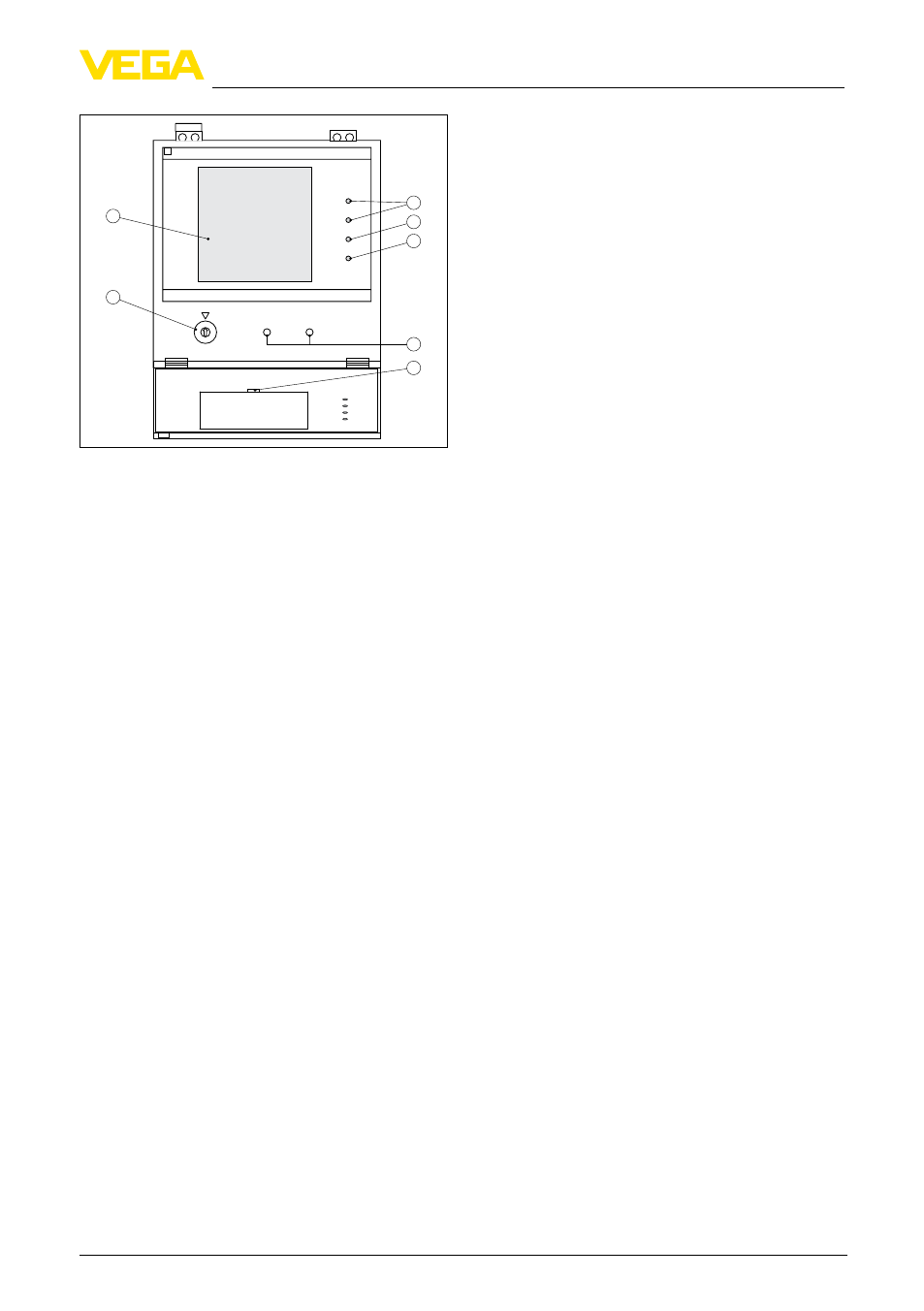

Abb. 14: Display and adjustment elements

1 Status indication operating relay 1 and 2

2 Status indication fail safe relay

3 Status indication operation

4 Adjustment keys +/-

5 Insertable tag for identification of the measure-

ment loop

6 Function switch

7 LC display

Key functions

•

[Function switch] for selection of:

– Adjustment

– Relay switching points

– Indication scaling

– Current output

– Integration time

– Offset correction

– Current input active/passive

•

[+/-] key:

– Change value of the parameters

By pushing the [+/-] key, you change the indivi-

dual parameters of the selected function. In this

phase, the processed parameter is flashing. By

briefly pushing the two keys simultaneously, you

save your settings. "Save" is briefly displayed.

6.2 Setup steps

Setup

Setup comprises mainly the adjustment of the

measurement loop. A scaling of the measured

value for the LC display and the adaptation of

the relay switching points are further settings.

Additional setup steps would be, if necessary,

setting an integration time (damping) to steady

the measured value or modifying the current

output characteristics.

To clearly denote the measuring unit, the

supplied labels can be inserted in the cover. In

case several VEGAMET 381 are used, each

measurement loop should be clearly labelled.

Switch-on phase

After being switched on, VEGAMET 381 first of

all carries out a short self-check. The following

steps are carried out:

•

Internal check of the electronics

•

Indication of the firmware version

•

The output signal jumps briefly to the set

fault value

Then the actual measured value is displayed

and the corresponding current is transmitted to

the current output.

Measured value indication

The measured value indication shows the digital

indication value and also an analogue bargraph.

Here, it is absolutely necessary that the function

switch is set to position [ 0] ("OPERATE").

Function switch

The following functions can be selected via the

rotary switch:

•

0: Measured value display and simulation

•

1: Relay 1 switching point ON

•

2: Relay 1 switching point OFF

•

3: Relay 2 switching point ON

•

2: Relay 2 switching point OFF

•

5: Decimal point position of the scaling

•

6: Scaling for 100 %

•

7: Scaling for 0 %

•

8: Switch over current output 0/4 … 20 mA

•

9: Damping of the measured value (integra-

tion time)

•

A: Offset correction

•

B: Min. adjustment in percent through

change of the level

•

C: Max. adjustment in percent through

change of the level

•

D: Min. adjustment in mA without changing

the level

•

E: Max. adjustment in mA without changing

the level

•

F: Changeover current input active/passive

Current input active/passive

•

In active mode, VEGAMET 381 provides the

power for the connected sensor. Power sup-