Accelabar model selection, Ready to install, Specifications chart a – Veris Accelabar Brochure User Manual

Page 6

Accelabar Model Selection

1. Furnish your flowing conditions. A flow

calculation is required to determine the

DP and verification of the operating limits.

• Each meter size has a standard beta ratio

sized for the optimal operating range.

• The maximum operating limits are deter-

mined by the Accelabar flow calculation.

2. If your flowing conditions exceed the operating limits, a larger or smaller model (meter size) must be selected.

6

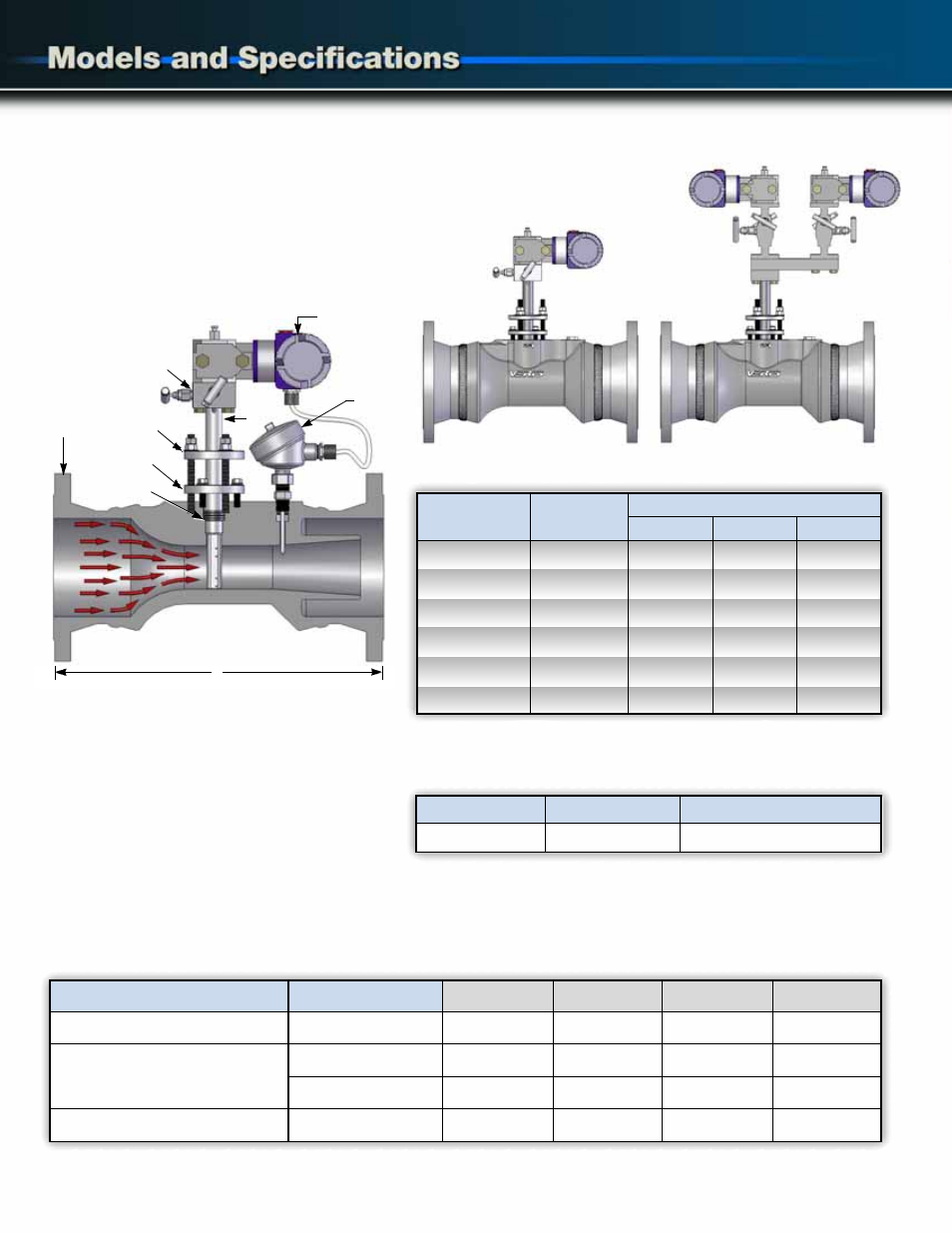

Ready to Install

The Accelabar is a complete flow meter

ready to install. It comes complete with

single or dual transmitters depending on the

turndown requirements.

An optional RTD is supplied in a Thermowell

for dynamic compensation (required for use

with multivariable transmitter).

Specifications

Chart A

Meter Size

Verabar

Face to Face “L”*

Sensor

150#

300#

600#

3” (75mm)

-05 1/2”

13.78”

14.53”

15.28”

4” (100mm)

-05 1/2”

15.15”

15.90”

17.65”

6” (150mm)

-10 1”

19.15”

19.90”

21.90”

8” (200mm)

-10 1”

21.40”

22.15”

24.40”

10” (250mm)

-10 1”

23.15”

24.40”

27.65”

12” (300mm)

-10 1”

26.17”

27.78”

29.67”

AF Flanged

Model

Single Transmitter

Dual Transmitter

Flowing Conditions

*Density is not required for steam applications.

General Data

Fluid Parameters

Maximum

Normal

Minimum

Units

Tag number

Flow Rate

Pipe size & schedule or

Pressure

exact ID & wall thickness

Temperature

Fluid name:

Density*

Accuracy

Repeatability

Sensor, Body & Flange

to ± 0.50%

±0.050%

316SS

Accelabar flow nozzle

Graphite

packing

Packing follower

Weld neck

RF flange

Verabar

Transmitter

RTD

(optional)

Retaining

plate

Manifold

head

L

* Face to face dimensions nominal. Custom lengths available.