Veris Verabar V110 Spec Sheet User Manual

Verabar, Regular models

The Most Accurate and Reliable Technology

for Measuring Gas, Liquid and Steam…

Developed from aerospace technology,

the Verabar

®

averaging pitot flow

sensor provides unsurpassed

accuracy and reliability.

With its solid, one-piece

construction and bullet

shape, the Verabar

makes flow

measurement

leak proof

and precise.

The unique

sensor shape

reduces drag and flow induced vibration. The location

of the low-pressure ports eliminates the potential for

clogging and improves signal stability.

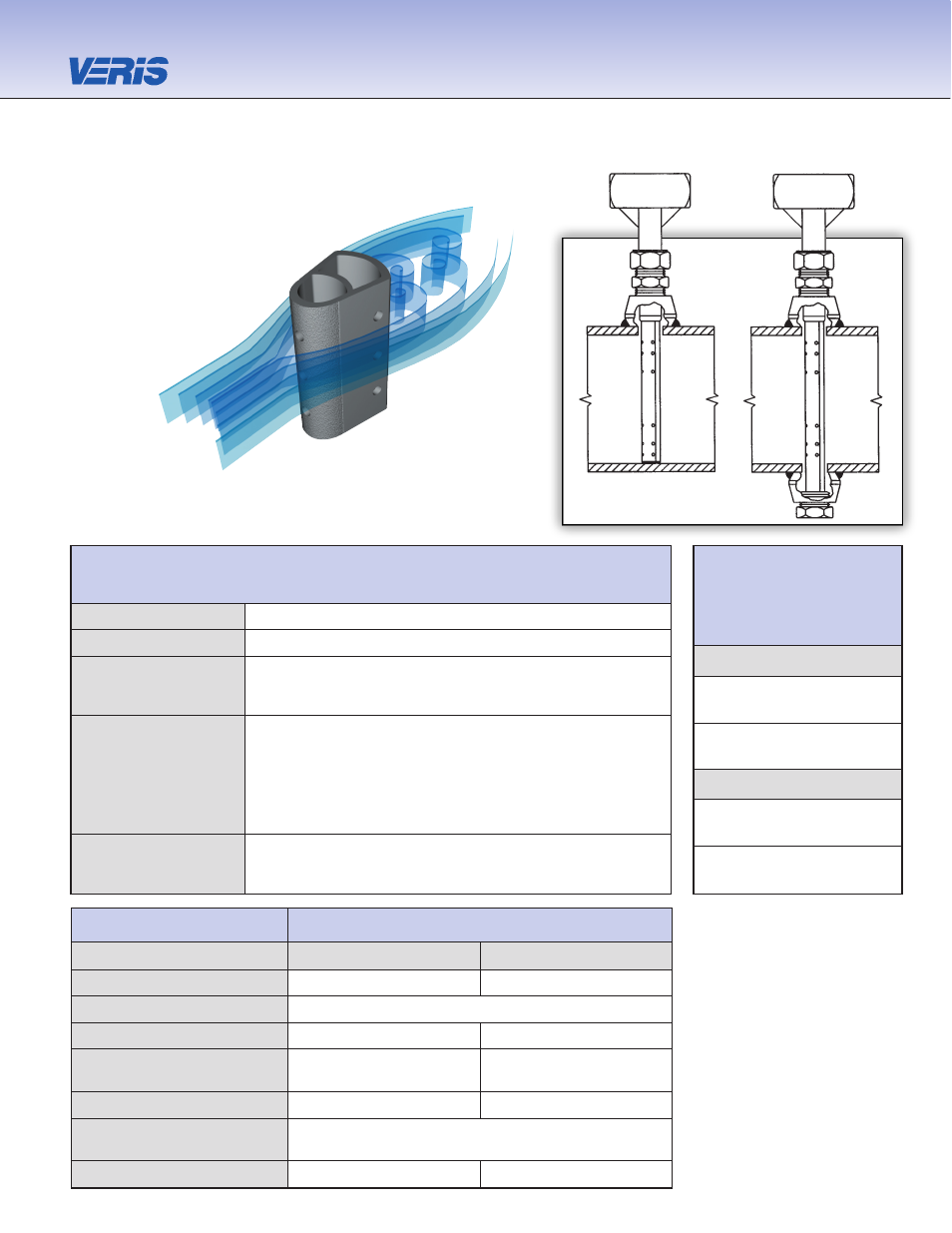

Regular Models

V100 & V110 Compression Fitting

Differential Pressure Flow Sensors

Verabar

®

Model

V110

Model

V100

V100 Single Support

V110 Opposite Support

Pipe Connection

Threaded (NPT)

Mounting Type

Tube fitting

Features and

• Most cost effective model

Benefits

• Installed in less than one hour

• Low and medium pressures

• Pipes (steel, PVC, FRP, copper)

• Air (compressed, combustion)

• Natural gas

Applications

• Stack/flue gas

• Water (raw, cooling, feedwater)

• Low pressure steam

• Non-hazardous fluids

Special Designs —

• Custom mounting, lengths, materials,

Consult Factory

instrument connections, etc.

• Short straight run

Temperature

Pressure

Limits

(ANSI Class)*

300#

740 psig @ 100°F

(51.0 Bars @ 38°C)

410 psig @ 800°F

(28.3 Bars @ 426°C)

600#

1440 psig @ 100°F

(99.3 Bars @ 38°C)

825 psig @ 800°F

(56.9 Bars @ 426°C)

* DIN and JIS flanges available. Consult factory.

Model Specifications

V100 and V110

Sensor Code

05

10

Sensor Diameter

7/16” (11mm)

7/8” (22mm)

Accuracy

±1% of flow rate; ±0.5% if calibrated

ANSI Class*

600#

300#

Pipe Size

2”- 6”

6”- 48”

(50mm -150mm)

(150mm -1200mm)

Instrument Connection

1/2” NPT

1/2” NPT or Direct Mount

Components Furnished

Weld coupling, tube fitting;

V110 includes additional weld coupling and plug

Weld Coupling Size

3/4” NPT

1” NPT