Section 4 - selecting check paper and micr toner, Selecting check paper – TROY Group MICR Basics Handbook User Manual

Page 17

Section 4 Selecting Check Paper and MICR Toner

MICR Basics Handbook -- Document #50-70300-001 Rev. C

4-1

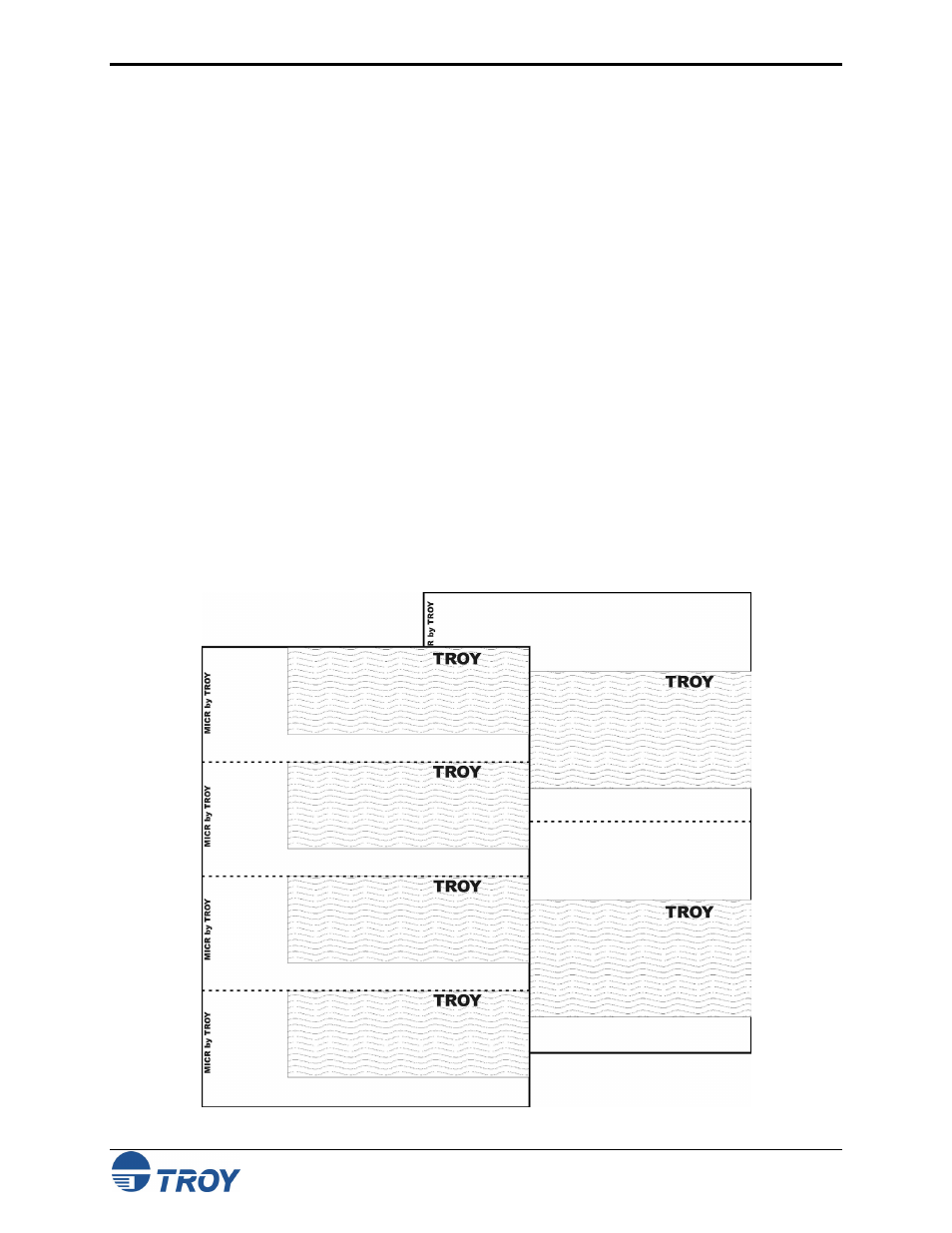

Selecting Check Paper

During a typical processing cycle, a check may pass through high-speed readers/sorters as many as 30

times. If the proper check paper is not used, the check could easily become damaged. If damage occurs

at the beginning of the processing cycle, the check may not feed into subsequent machines. Damaged

documents must be repaired before being re-entered into subsequent reader/sorter machines.

Inexpensive paper may save you money in the short term; however, the finished documents may not

survive the processing cycle and may cause a marked increase in rejected documents at your banking

operation centers and clearing houses. Most of these establishments keep accurate records on problem

checks. Continued use of inferior check stock could ultimately result in fines from these clearing houses

and/or outright rejection of all of your subsequent checks.

After learning about the paper requirements in the following sections, you will find that TROY’s

premium quality security check paper will give you the best results. TROY’s premium quality security

check paper is made specifically for printing checks. If you wish to order your paper stock from your

own source, show the paper requirements outlined in this section to the sales representative.

If you are uncertain about the characteristics of your paper stock, TROY’s state-of-the-art paper and print

quality laboratory will test your paper forms and print quality for a nominal fee. For more information on

this service or to obtain TROY premium quality check paper, call: (800) 332-6427 (MICR).

NOTE:

This section provides details for MICR specifications and

guidelines that apply to the United States. For information

on International MICR specifications and guidelines, refer

to the ISO-1004 standards document.