Slip member and boot installation, Driveshaft installation – Spicer Driveshafts Service Manual User Manual

Page 29

26

Driveshaft

Installation

Note: If the application requires the installation of a slinger,

avoid damage during installation.

Note: Do not reuse old slingers. Most replacement center

bearings will not include slingers.

3.

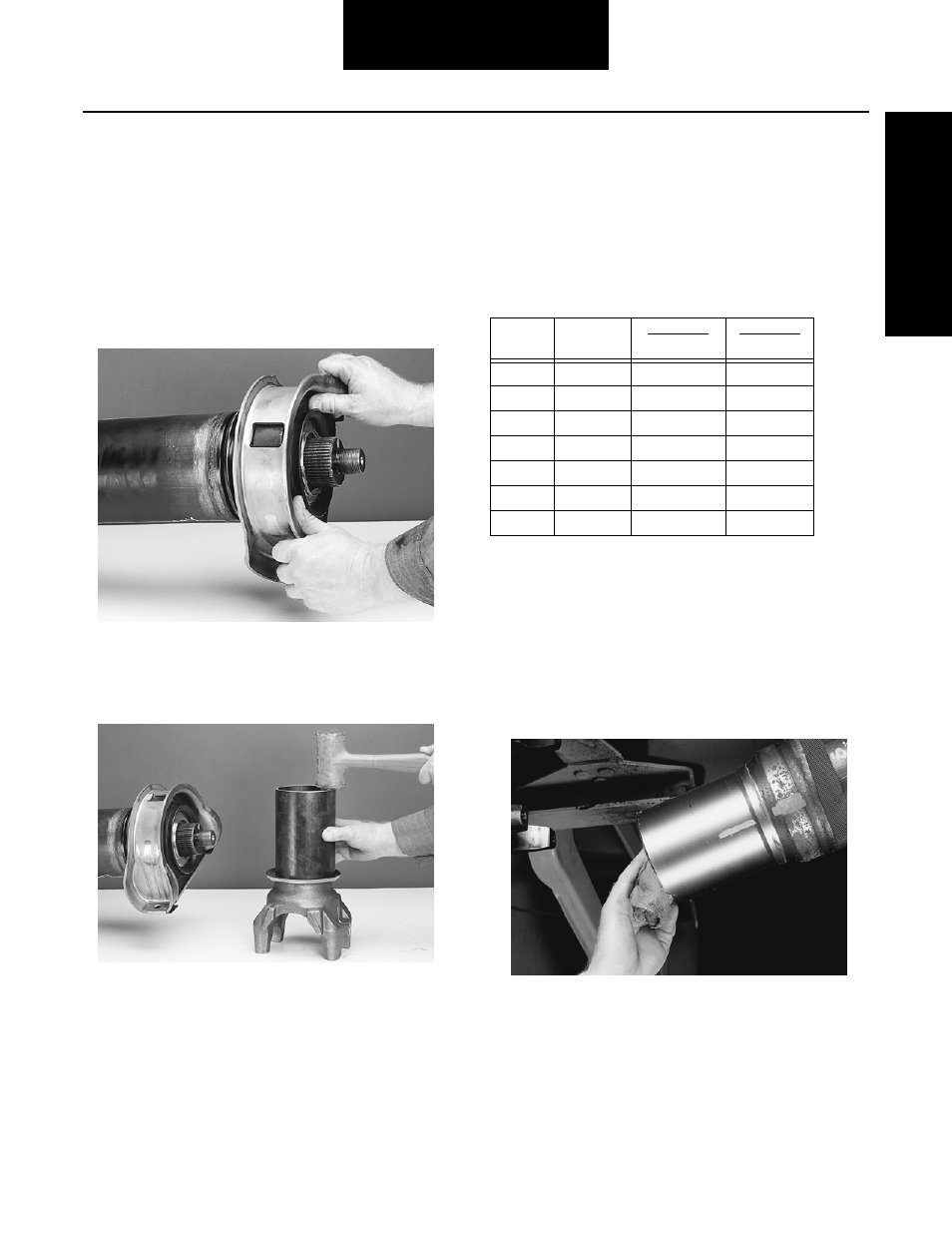

Carefully align the new center bearing assembly with

the ground surface of the midship tube shaft. Physi-

cally push the center bearing onto the midship tube

shaft.

4.

Press remaining slinger on end yoke using a section

of tubing to avoid damaging slinger.

5.

Using a soft-faced hammer, drive the yoke onto mid-

ship tube shaft, making sure phasing marks from

driveshaft removal procedure are in line. Continue to

tap the yoke until it is completely seated against the

center bearing.

Note: Only drive (press) off the washer face of the yoke. Never

hammer or press on the ears of the yoke. See illustra-

tion

6.

Install a washer (if required) and new midship nut

and torque nut to specifications. See midship nut

specifications, Table MM.

Failure to torque midship nut to required specifications can

cause driveline failure, which can result in separation of the

driveline from the vehicle. A separated driveline can result in

property damage, serious personal injury or death.

Slip Member and Boot Installation

1.

Clean ALL grease from yoke shaft and spline sleeve.

Make sure grease-cutting solvent does not intrude

into the tube through the vent hole in the spline

sleeve plug. Be sure the phasing marks made during

disassembly are not removed.

Table MM - Midship Nut Specifications

Series

Head Size*

Nut Torque

Nm

Nut Torque

LB. FT.

SPL55

1 5/16"

542-610

400-450

SPL70

1 5/8"

644-712

475-525

SPL90

1 5/8"

644-712

475-525

SPL100

1 5/8"

644-712

475-525

SPL140

41mm*

644-712

475-525

SPL170

41mm*

644-712

475-525

SPL250

41mm*

644-712

475-525