Center bearing installation, Driveshaft – Spicer Driveshafts Service Manual User Manual

Page 28

25

Driveshaft

3.

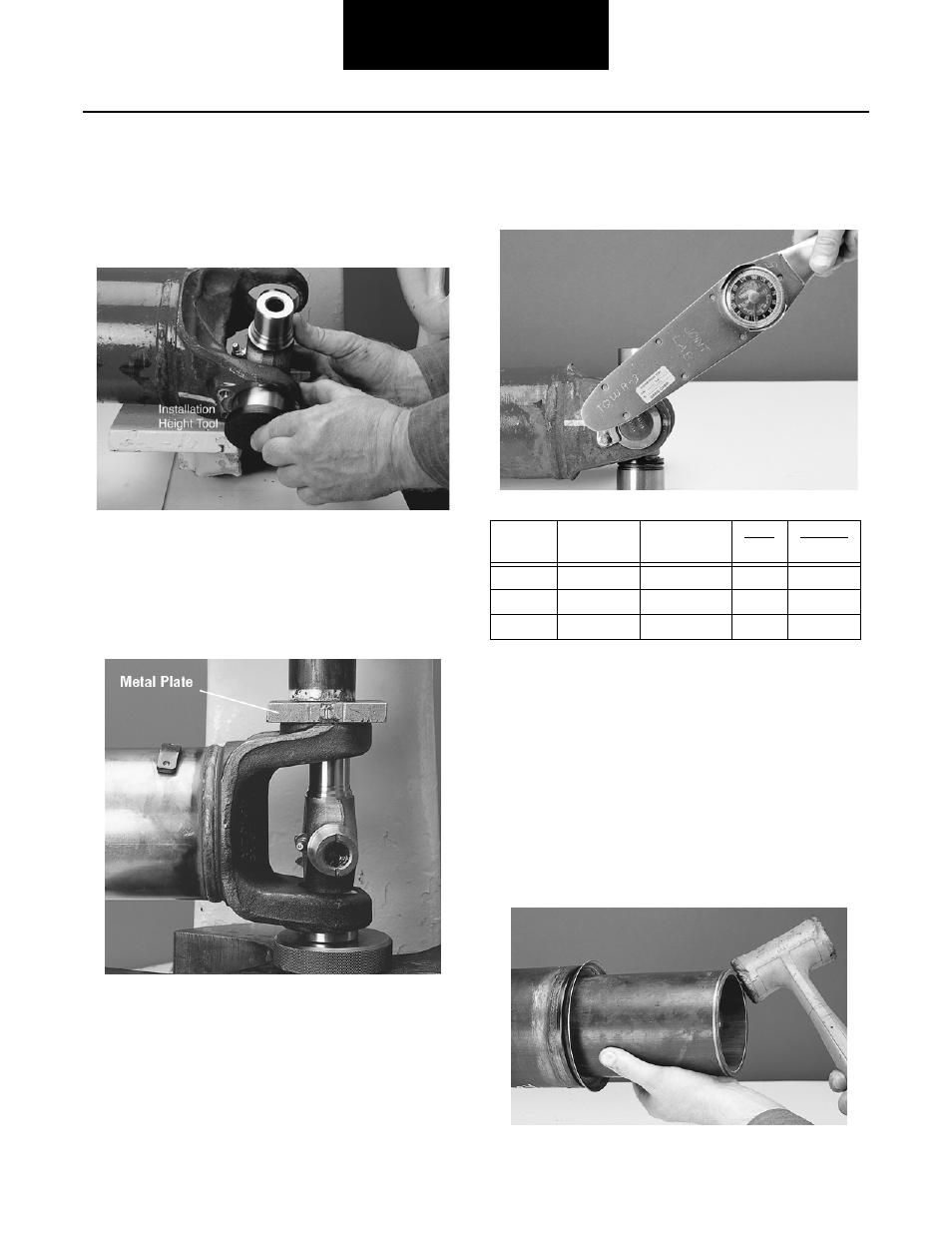

Move one end of the journal cross to cause a trun-

nion to project through the cross hole beyond the

outer machined face of the yoke ear. Take one bear-

ing cup assembly and position an installation height

tool on the end of the bearing cup assembly. Place

the bearing cup assembly over the protruding trun-

nion diameter and align it to the yoke cross.

4.

Align the yoke in an arbor press with the bearing

assembly resting on the base of the press. Cover the

yoke ear with a metal plate that has 0.25 inch (6.4

mm) minimum thickness. Push the yoke onto the

bearing cup assembly until it is flush with the cross

hole face. Do not remove the installation height

tool.

5.

Flip yoke 180 degrees. Position the remaining

installation heigh tool on the end of another bearing

cup assembly. Place bearing cup assembly over

trunnion diameter and align it to the yoke cross hole.

Push the bearing cup assembly until both installation

height tools are flush with the cross hole face.

6.

Install new spring tabs and 8mm thread bolts. Make

sure that no grease or foreign material is present

between the contact areas of the spring tabs, bearing

cups and yoke cross hole faces. Tighten bolts to the

required torque.

*Bolts are specially heat-treated.

DO NOT substitute inferior grade bolts.

Center Bearing Installation

1.

Wipe the bearing surface of the midship tube shaft

with a fine emery cloth.

2.

Install a new slinger (included in center bearing

replacement kit) on the midship tube shaft using a

section of tubing to avoid damaging slinger. Make

sure the slinger is completely seated against the

midship tube shaft shoulder

SPRING TAB BOLT SPECIFICATIONS

SERIES

THREAD

SIZE

HEAD SIZE

BOLT

Nm

TORQUE

LB. FT.

SPL140

8mm x 1.00

8mm, 6 point

34-41

25-30

SPL170

8mm x 1.00

8mm, 6 point

34-41

25-30

SPL250

8mm x 1.00

8mm, 6 point

34-41

25-30