Spicer DS404 Reinforcing Instructions User Manual

Page 3

8.

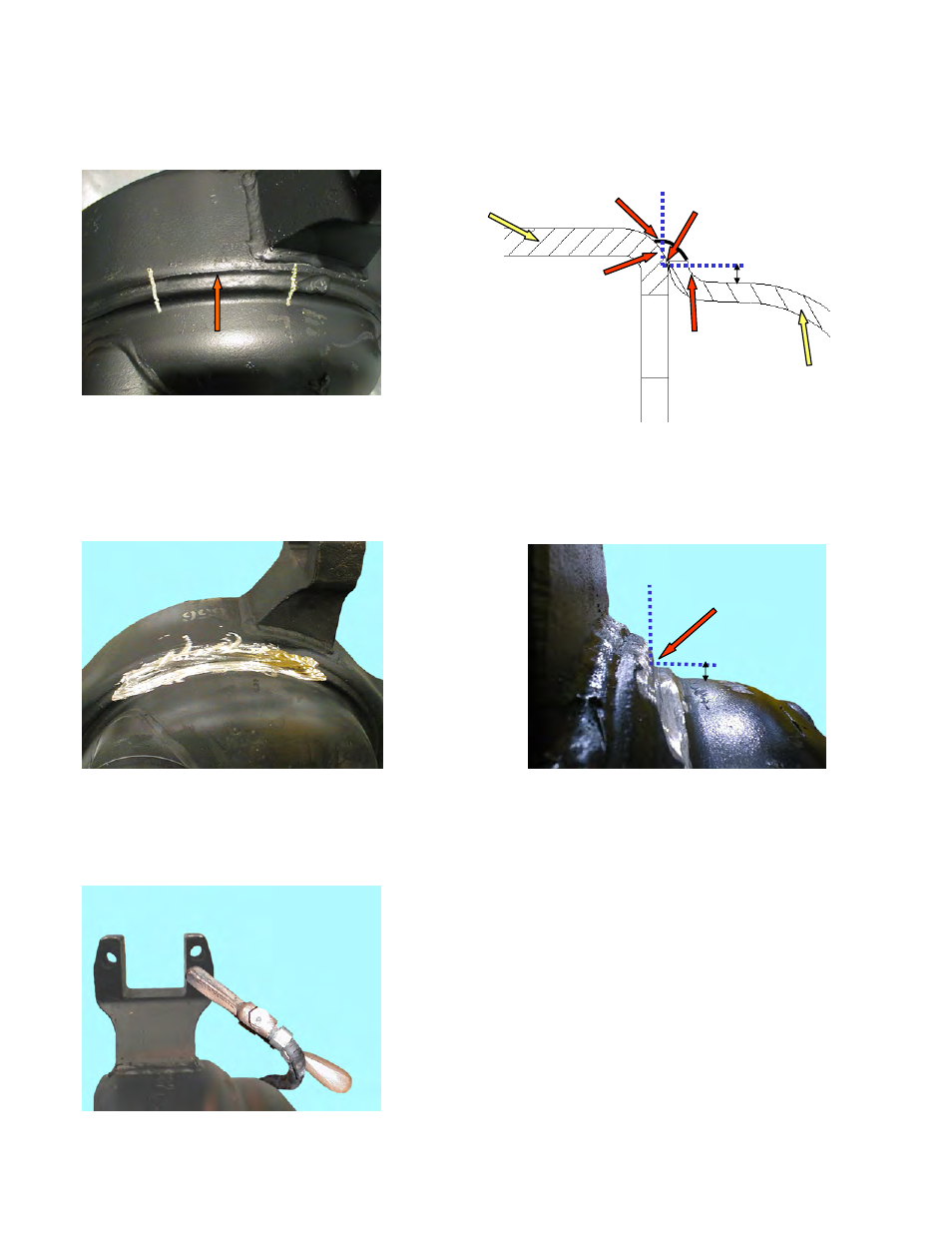

If the cover weld is NOT cracked on the outside of the weld, mark the housing 2 inches either side of the 12:00

position. Remember these cracks start on the inside of the housing and work their way out. You will need to grind

through the old weld to the fit-up line, this is where the cover meets the axle housing. You should have approximately

¼” of distance between the top of the cover to the bottom of the ground area. The blue dotted lines below represent

the area to be ground.

No Crack Outside Of Weld

9. Use a 4 inch angle grinder to grind away the crack. You must grind just below the old weld, down to the fit-up line.

Use the drawing above and the photo below as a guide. It’s very important that you recognize the difference between

the crack and the point where the cover meets the axle housing.

Caution*** Be careful to not break completely

through as this will contaminate the axle’s lubricant with grinding material.

Use a wire wheel to remove paint from area to be welded.

Grind Away Crack

Side view of Grind

10. For All Weld Passes Cover Weld – When using a Mig Welder use approximate setting of 30 volts and 180 amps. If

using an Arc welder, use E7018 1/8 inch electrode.

Important** The ground from the welder must be connected to the torque rod bracket. See figure below.

Ground Connection

12:00 Position

Grind Profile

Approximate

Depth

Fit-Up Line

Cover

Housing

Old Weld

Cover

Radius

1/4”

Area To Be

Ground

1/4”