Spicer DS404 Reinforcing Instructions User Manual

Spicer, Axles & brakes, Ds404 housing cover weld reinforcing instructions

Spicer

®

Axles & Brakes

P/N: SHAIS132

DS404 Housing Cover Weld Reinforcing Instructions

Subject of Instruction Sheet:

The procedure below has been created to assist a mechanical technician in the proper

repair of a cracked rear cover weld and the installation of a reinforcement bracket on DS404 housings in Peterbilt vehicles

using an Air Leaf Suspension. This is the

only approved method for this repair. Any other method of repair may result in

damage to the axle, axle housing, or other vehicle components and could affect performance and safety. Failure to follow

all steps of this procedure will result in a poor repair and the crack could occur again.

Affected Models:

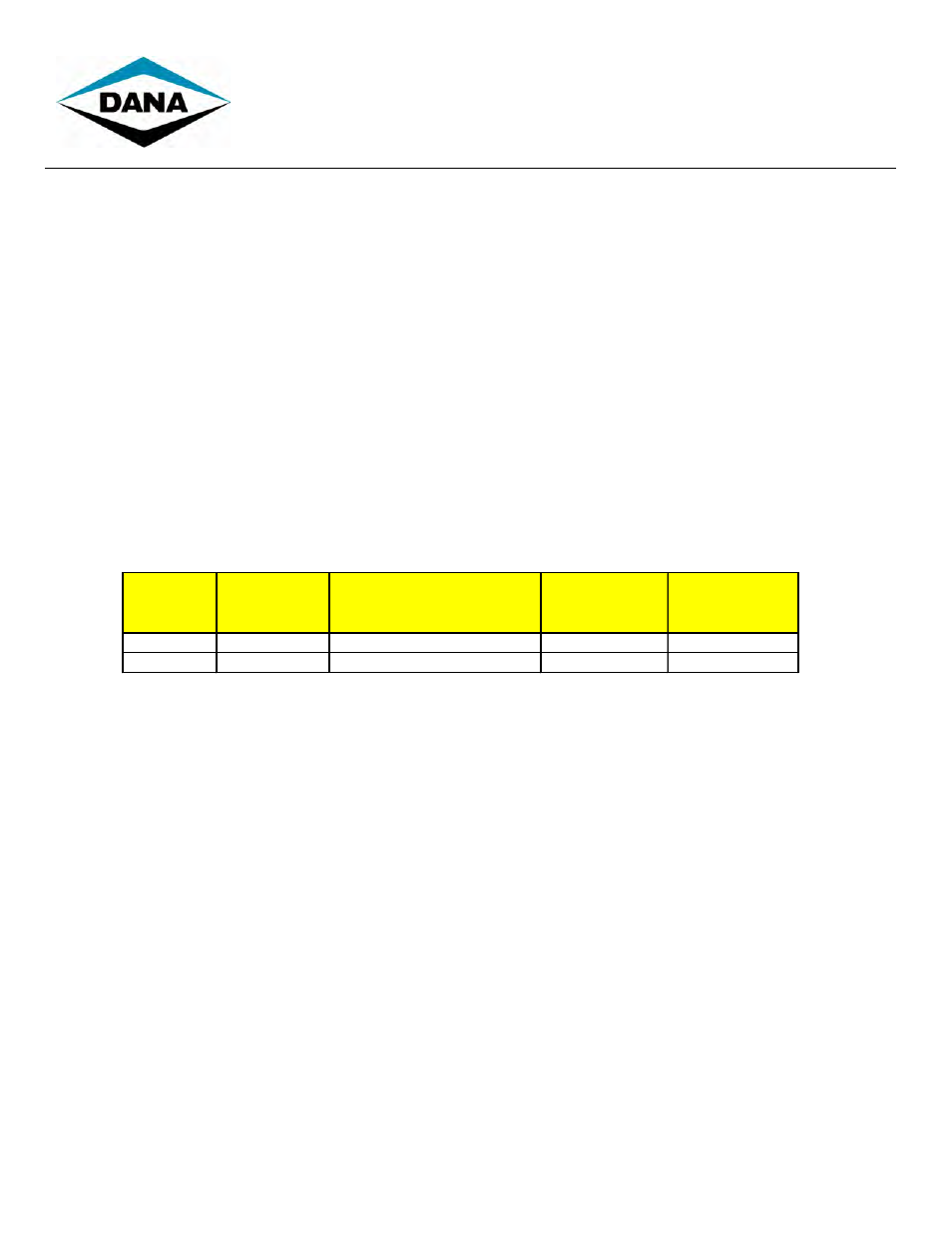

DS404 Drive Housing Used in Peterbilt Air Leaf Suspension Vehicles. See chart

below.

Axle Model

Wall

Thickness

Suspension Type and

Timing

Production

Housing P/N On

Tag

Production

Brackets Welded

By:

DS404

3/8" (9.5mm)

Air Leaf - Before 3/99

319402

Peterbilt

DS404

3/8" (9.5mm)

Air Leaf - From 3/99 - 6/00

319954

Dana

Reinforcing Bracket Part Number 302527

Welding Equipment and Specifications

:

Mig (wire) Welding

Welding Gas – recommended – 80% Argon, 20% C-O2 Gas Flow Setting – 50-60 cfh.

Wire Size – ER70S-3 or ER70S-6 .035”

First and second passes cover weld, approximate settings – 30 volts, 180 amps.

Third filler pass, cover weld, approximate settings – 26 volts, 140 amps.

Apply three weld passes to the cover and two to the bracket. The first pass should be centered over the fit-up line and

penetrate the failure area. The second pass should be placed slightly above the first. Blend the weld smoothly ( without

significant cross section enlargement ) with the housing and first pass. The third pass should penetrate the lower half of

the second pass to the edge of the housing cover. Avoid any significant overlap of weld or undercut. When making the

second and third passes the weld direction should be reversed. Always start the weld at one end, never in the middle the

intended weld area. See illustrations below for more information.

Arc (stick) Welding

Miller DC type stick welder set at 140 -150 amp setting.

Use E7018 1/8 inch Electrode for all three passes. Note** Remove slag between

passes. E7018 rod must be stored in

heated rod oven. Apply three weld passes to the cover and two to the bracket. The first pass should be centered over the

fit-up line and penetrate the failure area. The second pass should be placed slightly above the first. Blend the weld

smoothly ( without significant cross section enlargement ) with the housing and first pass. The third pass should penetrate

the lower half of the second pass to the edge of the housing cover. Avoid any significant overlap of weld or undercut.

When making the second and third passes the weld direction should be reversed. Always start the weld at one end, never

in the middle the intended weld area. See illustrations below for more information. When welding the second and third

passes, reverse the direction of the weld. Never start or stop a weld close to the 12:00 position.