Spicer Single Drive Axles Service Manual: S170, S190, S590 User Manual

Page 31

27

Wheel Differential

Wheel Differential

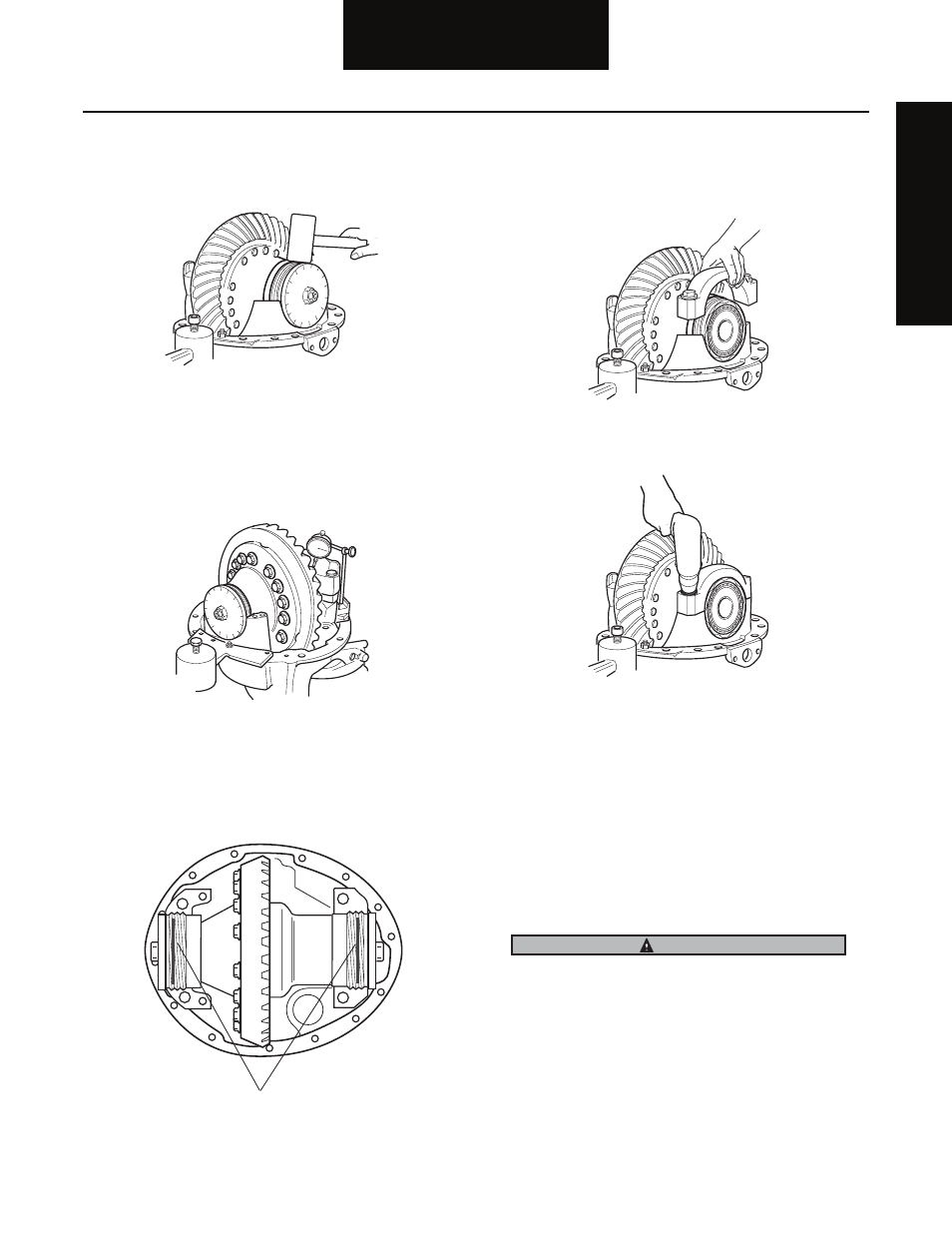

8. Use a rubber mallet to fully seat the threaded bearing

cups.

9. With a dial indicator, check the ring and pinion back-

lash. Set the backlash from 0.010" to 0.012". This

will give you room to adjust the contact pattern, if

necessary.

10. Remove the adjuster plates and threaded rod

assembly.

11. Apply a 1/8” bead of Loctite 540 to the exposed

threads of the bearing adjuster.

12. Install the carrier differential bearing caps and cap-

screws. Make certain there is no gap between the

carrier cap and the carrier surface.

13. Use an impact gun to snug all carrier

cap fasteners.

14. Recheck the backlash. For new gearing, the backlash

should be between 0.008" and 0.018" (0.20 and 0.46

mm).

Note: For used gearing, the backlash should be reset to what

it was at the time of disassembly.

Note: If you have too much backlash, move the ring gear

closer to the pinion. Count the number of notches you

back off the plain half threaded cup. Each notch equals

about 0.003" (0.08 mm) of backlash.

In order to maintain the differential bearing preload, you

will need to turn the flange half threaded cup the same

amount in the same direction. If you need more backlash,

reverse the procedure.

Apply Loctite 5 40

IMPORTANT