A.13 model 601 and energy absorption, A.13.1 model 601 specifications, Appendix – American Magnetics 05300PS-430-601 High Stability Integrated Power Supply System User Manual

Page 190

172

Rev. 5

Appendix

Model 601 and Energy Absorption

A.13 Model 601 and Energy Absorption

In order to provide magnet discharge current control with a unipolar

power supply, AMI introduces the Model 601 Energy Absorber into the

current loop (refer to “Dual-Quadrant Operation” on page 10 and Figure 3-

A.13.1

Model 601 Specifications

The AMI Model 601 Energy Absorber is designed to provide a compact,

fast-rampdown option of up to 5 Vdc for AMI power supply systems. The

Model 601 is designed to operate safely in the event of loss of facility ac

power by drawing the necessary power for internal cooling from the

superconducting magnet. Upon loss of ac power to a power supply system,

the Model 601 will ramp the system to zero current at a discharge rate of

approximately 5 Vdc.

A.13.2

Connecting Multiple Model 601 Energy Absorbers

The AMI 05300PS-430-601 bipolar power supply system incorporates

three Model 601 units operated in parallel. The positive (+) and negative

(-) lugs will be ganged together using conductive bus bars. The power

leads, from the supply and to the magnet, may be connected to any

mounting lug if an additional lug is not provided in the bus bar.

In addition to the ganged lugs, the coaxial connectors on the rear of each

Model 601 must all be connected together with coaxial cables — no BNC

terminators should be used. Use standard BNC “T” adaptors on the inner

unit.

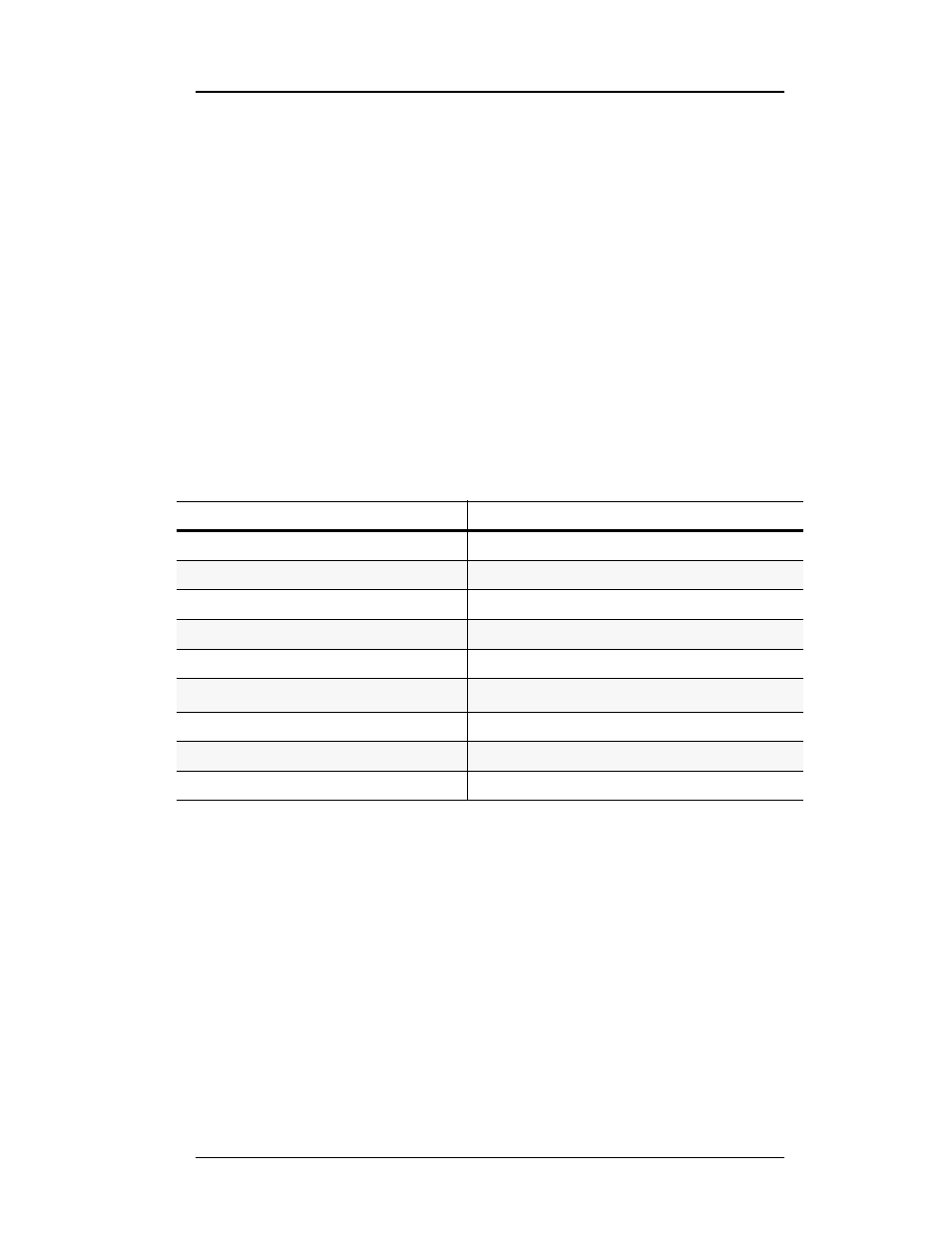

Table A-14.

Model 601 Energy Absorber Specifications

Parameter

Value

AC Input (to AC power adapter)

100 to 240 Vac ± 10%, 50/60 Hz, 100 VA max

DC Input (from AC power adapter)

5 Vdc ± 5%, 4 A max

Maximum Magnet Operating Current

130 A @ 25°C, derated linearly to 100 A @ 40°C

Nominal Discharge Voltage

5.0 Vdc ± 2%

Discharge Voltage Temperature Coefficient

± 150 ppm/°C max

Internal Series Resistance

a

a. Nominally adds 200 mV voltage drop at 100 A

2 m

Ω

± 1 m

Ω

Rated Operating Temperature

0 to 40°C @ 100 A, 0 to 25°C @ 130 A

Rated Operating Relative Humidity

0 to 95% non-condensing

Torque Limit on Current Terminals

48 lbf-in.