Bosch GWS 14-125 Inox Professional User Manual

Page 21

22 | English

1 609 92A 069 | (20.2.13)

Bosch Power Tools

To save energy, only switch the power tool on when using it.

Check grinding tools before using. The grinding tool

must be mounted properly and be able to move freely.

Carry out a test run for at least one minute with no load.

Do not use damaged, out-of-centre or vibrating grinding

tools. Damaged grinding tools can burst and cause injuries.

Kickback stop

In case of a sudden drop in speed, e.g.,

caused by a jammed disc while cutting, the

power supply to the motor is electronically

interrupted.

To restart the operation, switch the On/

Off switch 4 to the Off position and start the

machine again.

Restarting Protection

The restarting protection feature prevents uncontrolled re-

starting of the machine after an interruption in the power sup-

ply.

To restart the operation, switch the On/Off switch 4 to the

Off position and start the machine again.

Reduced starting current

The electronic reduced starting current limits the power con-

sumption when switching the tool on and enables operation

from a 13 ampere fuse.

Constant Electronic Control

Constant electronic control holds the speed constant at no-

load and under load, and ensures uniform working perfor-

mance.

Speed preselection

The required speed can be preselected with the thumbwheel 3 (also while running).

The data in the following table are recommended values.

Working Advice

Exercise caution when cutting slots in structural walls;

see Section “Information on Structures”.

Clamp the workpiece if it does not remain stationary

due to its own weight.

Do not strain the machine so heavily that it comes to a

standstill.

After heavily straining the power tool, continue to run

it at no-load for several minutes to cool down the acces-

sory.

Do not touch grinding and cutting discs before they

have cooled down. The discs can become very hot while

working.

Rough Grinding

Never use a cutting disc for roughing.

The best roughing results are achieved when setting the ma-

chine at an angle of 30° to 40°. Move the machine back and

forth with moderate pressure. In this manner, the workpiece

will not become too hot, does not discolour and no grooves

are formed.

Flap Disc

With the flap disc (accessory), curved surfaces and profiles

can be worked.

Flap discs have a considerably higher service life, lower noise

levels and lower sanding temperatures than conventional

sanding sheets.

Cutting Metal

For cutting with bonded abrasives, always use the pro-

tection guard for cutting 13.

When cutting, work with moderate feed, adapted to the mate-

rial being cut. Do not exert pressure onto the cutting disc, tilt

or oscillate the machine.

Do not reduce the speed of running down cutting discs by ap-

plying sideward pressure.

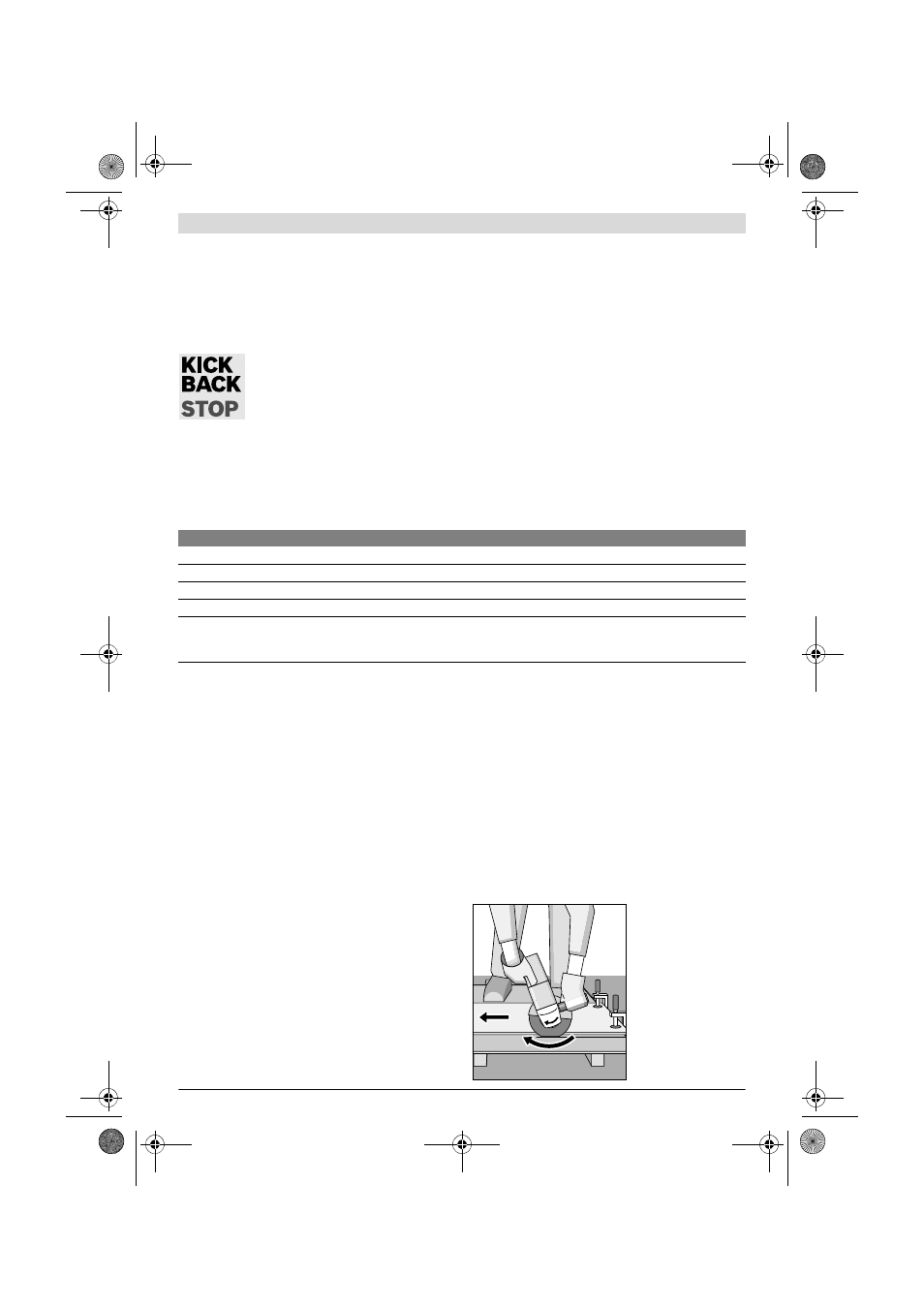

The machine must al-

ways work in an up-

grinding motion. Other-

wise, the danger exists

of it being pushed un-

controlled out of the

cut.

When cutting profiles

and square bar, it is best

to start at the smallest

cross section.

Material

Application

Accessory

Thumbwheel Position

Metal

Removing paint

Sanding disc

1 – 3

Wood, metal

Brushing, rust removal

Cup brush, sanding disc

3

Metal, masonry

Grinding

Grinding disc

4 – 6

Metal

Rough grinding

Grinding disc

6

Masonry, stone

Cutting

Cutting disc and cutting guide

(Cutting masonry/stone is permitted only with

use of the cutting guide)

6

OBJ_BUCH-611-005.book Page 22 Wednesday, February 20, 2013 9:29 AM