Assembly – Bosch GBH 3-28 DRE Professional User Manual

Page 15

English | 15

Bosch Power Tools

1 609 92A 043 | (10.1.13)

GBH 3-28 DRE/GBH 3-28 DFR:

The vibration emission level given in this information sheet has

been measured in accordance with a standardised test given in

EN 60745 and may be used to compare one tool with another.

It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main ap-

plications of the tool. However if the tool is used for different

applications, with different accessories or poorly maintained,

the vibration emission may differ. This may significantly in-

crease the exposure level over the total working period.

An estimation of the level of exposure to vibration should also

take into account the times when the tool is switched off or

when it is running but not actually doing the job. This may signif-

icantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator

from the effects of vibration such as: maintain the tool and the

accessories, keep hands warm, organise work patterns.

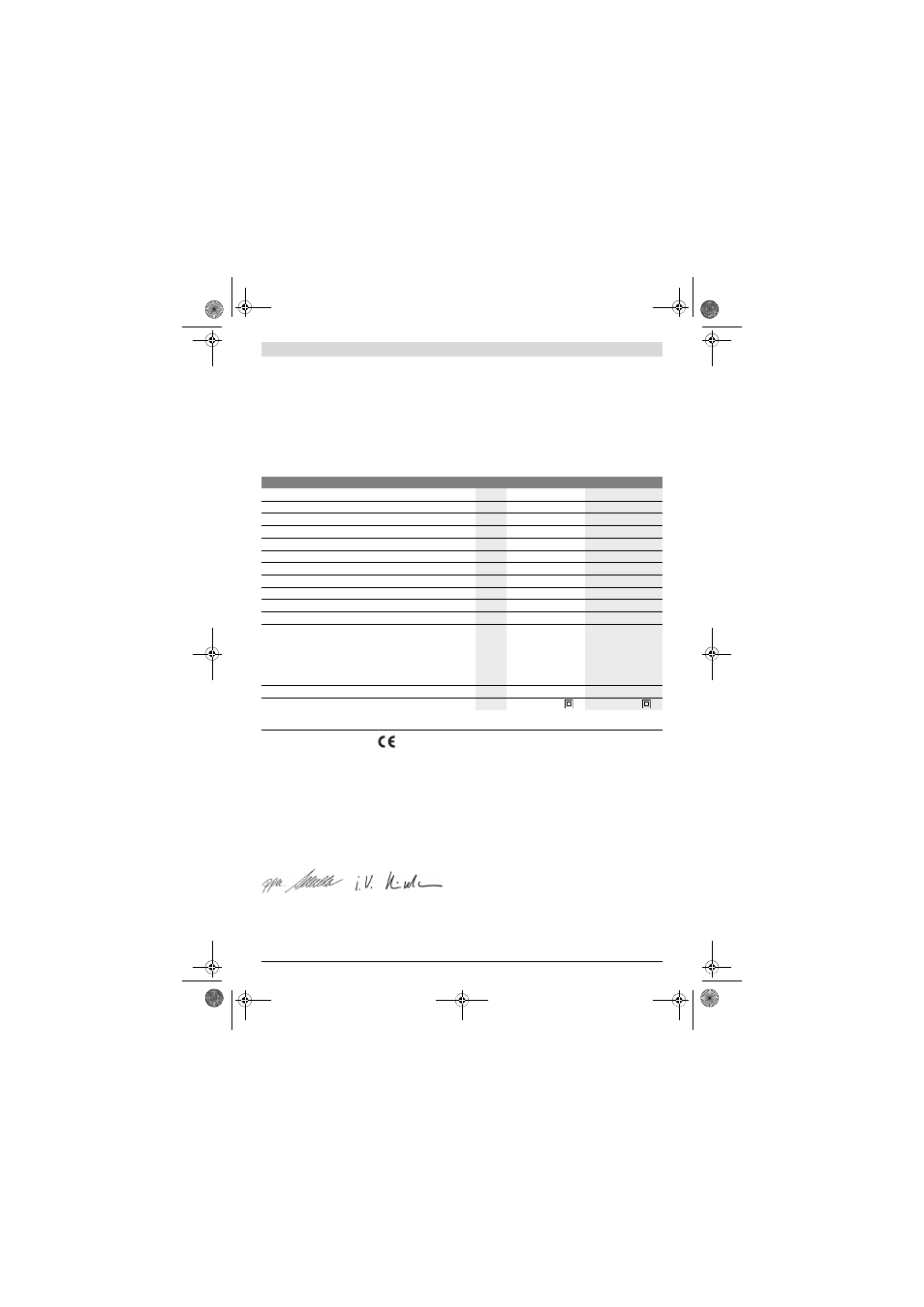

Technical Data

Declaration of Conformity

We declare under our sole responsibility that the product de-

scribed under “Technical Data” is in conformity with the fol-

lowing standards or standardization documents: EN 60745

according to the provisions of the directives 2011/65/EU,

2004/108/EC, 2006/42/EC.

Technical file (2006/42/EC) at:

Robert Bosch GmbH, PT/ETM9,

D-70745 Leinfelden-Echterdingen

Robert Bosch GmbH, Power Tools Division

D-70745 Leinfelden-Echterdingen

Leinfelden, 14.12.2012

Assembly

Before any work on the machine itself, pull the mains

plug.

Auxiliary Handle

Operate your machine only with the auxiliary handle 12.

Changing the position of the auxiliary handle

(see figure A)

The auxiliary handle 12 can be set to any position for a secure

and low-fatigue working posture.

– Turn the bottom part of the auxiliary handle 12 in counter-

clockwise direction and swivel the auxiliary handle 12 to

the desired position. Then retighten the bottom part of the

auxiliary handle 12 by turning in clockwise direction.

Pay attention that the clamping band of the auxiliary handle is

positioned in the groove on the housing as intended for.

Adjusting the Drilling Depth (see figure B)

The required drilling depth X can be set with the depth stop 11.

Rotary Hammer

GBH 3-28 DRE

GBH 3-28 DFR

Article number

3 611 B3A 0..

3 611 B4A 0..

Speed control

Stop rotation

Right/left rotation

Quick change chuck

–

Rated power input

W

800

800

Impact rate

min

-1

0 –4000

0 –4000

Impact energy per stroke according to EPTA-Procedure 05/2009

J

3.1

3.1

Speed

min

-1

0 –900

0 –900

Tool holder

SDS-plus

SDS-plus

Spindle collar diameter

mm

50

50

Permissible drilling diameter, max.:

(also see page 16)

– Concrete*

– Brickwork (with core bit)

– Steel

– Wood

mm

mm

mm

mm

28

82

13

30

28

82

13

30

Weight according to EPTA-Procedure 01/2003

kg

3.5

3.6

Protection class

/

II

/

II

*not suitable with core bit

The values given are valid for a nominal voltage [U] of 230 V. For different voltages and models for specific countries, these values can vary.

Dr. Egbert Schneider

Senior Vice President

Engineering

Helmut Heinzelmann

Head of Product Certification

PT/ETM9

OBJ_BUCH-770-006.book Page 15 Thursday, January 10, 2013 11:11 AM