K (black) panel printing, Black panel - compensation, Overlay - panel speed – Zebra Technologies P640I User Manual

Page 57: Overlay panel - compensation, Ribbon - position (mm)

980541-001 Rev. A

P640i Card Printer User Guide

47

K (Black) Panel Printing

Black Panel - Compensation:

Overlay - Panel Speed: Speed at which the “OP”

overlay panel, if any, is printed (rarely used in printers

with laminating capability). If a Uv ribbon is selected,

the text changes to say “Uv Panel Speed”.

Overlay Panel - Compensation: Mainly used

with Uv ribbon to optimize the appearance of ultra-

violet-visible text.

Ribbon - Position (mm): This has to do with

positioning the color ribbon relative to the print head

such that when the head descends it lands solidly

within

the panel, not too early, not too late. Keep in mind the

following:

•

While the head is down and printing, ribbon

motion is controlled by the card itself, not by

the ribbon takeup (which at this time serves

only to peel the ribbon cleanly off the card).

•

The color panels are about ½" (12 mm)

longer than the image printed on the card.

This means that between one color printing

pass and the next, when the head briefly lifts,

the takeup drive has to shift the ribbon

rapidly to bring the next color panel under the

head.

•

The transition from one panel to the next in

the color ribbon is marked by a black stripe

which activates the ribbon sensor below the

supply roll. It is used, together with a count of

pulses from the motion sensor, to determine

ribbon position.

Unlike YMC color printing, which is required only

to deliver realistic portraits and pleasing graphics,

the K panel serves a more quantifiable purpose,

namely machine readability. In practically all

instances of K panel usage, there is a requirement

both for bar codes and well defined text - and

sometimes for signatures, which can be ìspideryî in

appearance unless compensated for. Unfortunately,

these requirements are in opposite corners.

The P640i provides three controls for K panel

printing: these are:

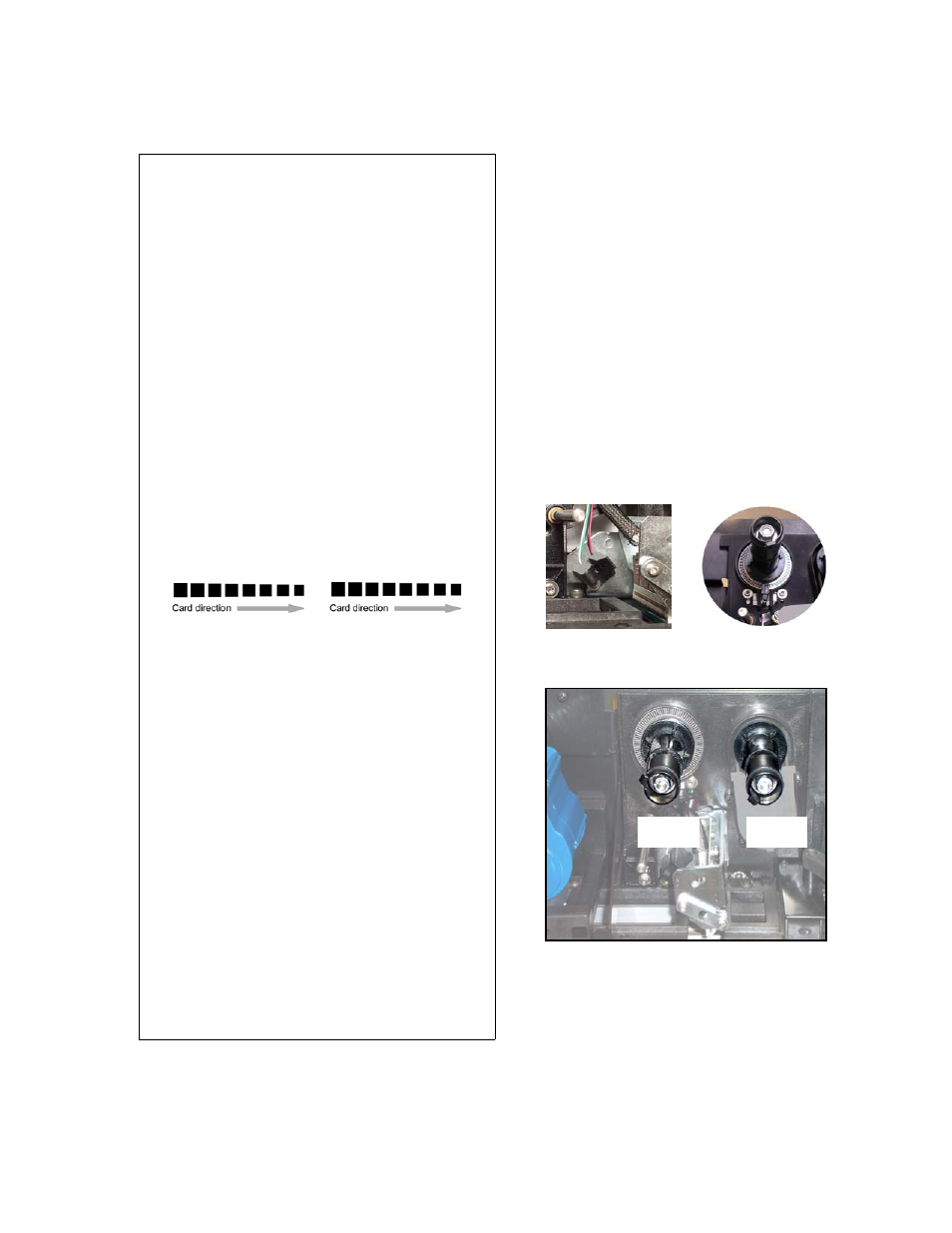

1.

Black panel compensation (Adjustment

screen, this page TN4 - x) If a line of black dots

is printed along the card motion axis, the

heating element (pixel) in question doesn’t

cool down completely between adjacent dots.

Without compensation, the steadily increasing

residual heat would cause the printed dot to

increase noticeably in size (“bloom”), below

left. Properly compensated, the dot size is

reasonably constant, below right.

2.

Black panel density (Color Calibration screen,

page TN4 - x) This control the amount of heat

energy applied to any pixel required to be

“black”. A higher value gives darker printing,

but can cause undesirable blooming (indefinite

edges).

3.

Black panel preheat (Color Calibration

screen, page TN4 - x) Think of this as a

temperature offset applied across the entire

head, specifically for K panel printing. A higher

value results in better resin transfer on the

leading edge of graphics and text than you

would get with a “cold start”, but it may lead to

undesirable blooming (indefinite edges)

overall.

The following default values deliver a good

compromise between barcode readability and the

appearance of text and signatures: Compensation

55, Density 117, Preheat 15

Without compensation

With compensation

Ribbon sensor

Motion sensor

Supply

arbor

Takeup

arbor