Carburetor adjustment, Ghs “full” signal horn with grass-pak® switch, Troubleshooting (when horn fails to operate) – Walker MT User Manual

Page 85: Maintenance instructions, Danger, Warning

Maintenance Instructions

ADJUSTMENTS

81

2.

Preliminary Setting: Turn the idle mixture nee-

dle valve out (counterclockwise) 1-1/2 turns

from the closed position. This initial adjust-

ment will allow the engine to be started and

warmed up prior to the final adjustment.

Carburetor Adjustment

3.

Start the engine and allow it to warm up by run-

ning at 1/2 throttle for approximately five (5)

minutes. The engine must be warm before

making final settings.

4.

Move the throttle to the idle position. Adjust idle

speed for 1200 rpm (± 75 rpm) by adjusting the

idle speed screw. Check the idle speed using a

tachometer.

5.

With the engine idling, adjust the idle mixture by

turning the idle mixture needle valve in (slowly)

from the preliminary setting until engine speed

decreases and then back out approximately 3/4

to 1 turn to obtain the best low speed perfor-

mance.

6.

Recheck idle speed after the final idle mixture

adjustment.

GHS “Full” Signal Horn with Grass-Pak

®

Switch

If the GHS “full” signal horn is not sounding or is not

adjusted to sound when the catcher is full, the fol-

lowing troubleshooting and adjustment instructions

apply:

Troubleshooting (When Horn Fails to Operate)

1.

Check the horn.

a.

Disconnect the two wires from the Grass-

Pak

®

switch electric connector plug and

make a jumper wire connection between

these wires (bypassing switch).

b.

Turn the ignition switch ON and move the

blade clutch to the ENGAGED position

(engine not running) to make the horn

sound.

c.

If the horn does not sound, the horn is bad

and needs to be replaced.

d.

If the horn does sound, proceed to step 2.

2.

Check the Grass-Pak

®

switch.

a.

Reconnect the wires to the Grass-Pak

®

switch electric connector plug.

b.

Turn the ignition switch ON and move the

blade clutch to the ENGAGED position

(engine not running).

c.

Open the catcher back door and trigger the

Grass-Pak

®

vane by hand as it oscillates.

d.

The horn should sound as the switch is

moved in both directions. If the horn does

not sound, the switch is bad and needs to

be replaced.

DANGER

The engine must be running to adjust the

carburetor for engine idle. To guard

against injury, keep hands, feet, face, and

other parts of body away from the muffler/

exhaust pipe, other hot parts of the engine,

and moving or rotating parts of the engine.

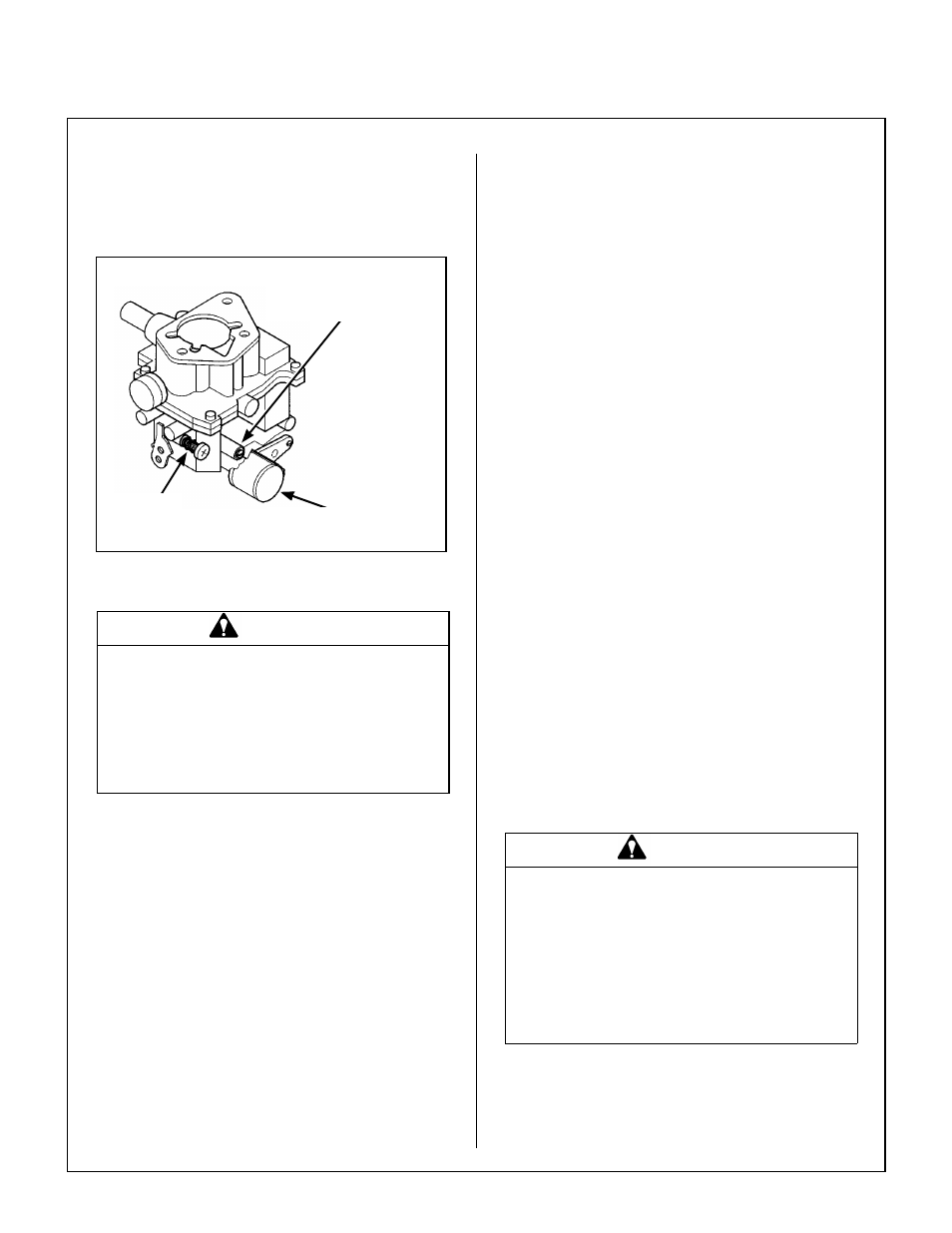

Low Idle Mixture

Needle Valve

(May be Non-Adjustable)

Fixed Main Jet Under

Shutdown Solenoid

Idle Speed

Screw

WARNING

PINCH POINT - SPRING LOADED DOOR

When lowering the door on the GHS catch-

er, depress the safety latch on the side of

the catcher as the door closes. The springs

that hold the door closed during operation

are very powerful, and the door CAN slam

shut with considerable force.